Leave Your Message

In the rapidly evolving landscape of modern manufacturing, the adoption of advanced technologies is crucial for maintaining competitiveness and efficiency. Among these innovations, the Electric Ultrasonic Welder has emerged as a pivotal tool that not only enhances operational productivity but also contributes to sustainable practices. According to a report by MarketsandMarkets, the ultrasonic welding market is projected to reach $1.8 billion by 2025, driven by increased demand for high-quality, automated assembly processes in various sectors, including automotive and electronics.

The precision and speed of Electric Ultrasonic Welders enable manufacturers to produce cleaner, stronger, and more reliable joints, while also minimizing material waste and energy consumption. As industries continue to seek smarter solutions, understanding the extensive benefits offered by Electric Ultrasonic Welders becomes essential for maximizing manufacturing efficiency and achieving long-term success.

Electric ultrasonic welding technology is revolutionizing the manufacturing sector by providing a plethora of advantages over traditional welding methods. One significant benefit is the enhanced precision and control it offers, leading to fewer defects and higher quality finishes. According to a report by Market Research Future, the ultrasonic welding market is projected to reach USD 10.5 billion by 2026, reflecting the growing acceptance of this technology in various industries, including automotive and electronics.

Moreover, electric ultrasonic welders are noted for their energy efficiency. They typically consume less energy than traditional welding techniques, reducing both operational costs and carbon footprints. A study by ResearchAndMarkets indicates that energy-efficient welding solutions can decrease energy consumption by up to 30%, a factor that is increasingly important in today’s eco-conscious manufacturing landscape.

Tip: For manufacturers looking to implement electric ultrasonic welding, consider investing in training programs for your team. Knowledge of the technology can significantly enhance output quality and operational efficiency.

In addition to their operational benefits, electric ultrasonic welders are also highly versatile. They can be used to join a wide range of materials, including plastics and metals, which broadens their applicability in different manufacturing scenarios. A comprehensive report by Technavio highlights that over 40% of manufacturers are now integrating ultrasonic welding into their processes to capitalize on these advantages.

Tip: Evaluate your current production processes to identify areas where ultrasonic welding can improve efficiency and product quality.

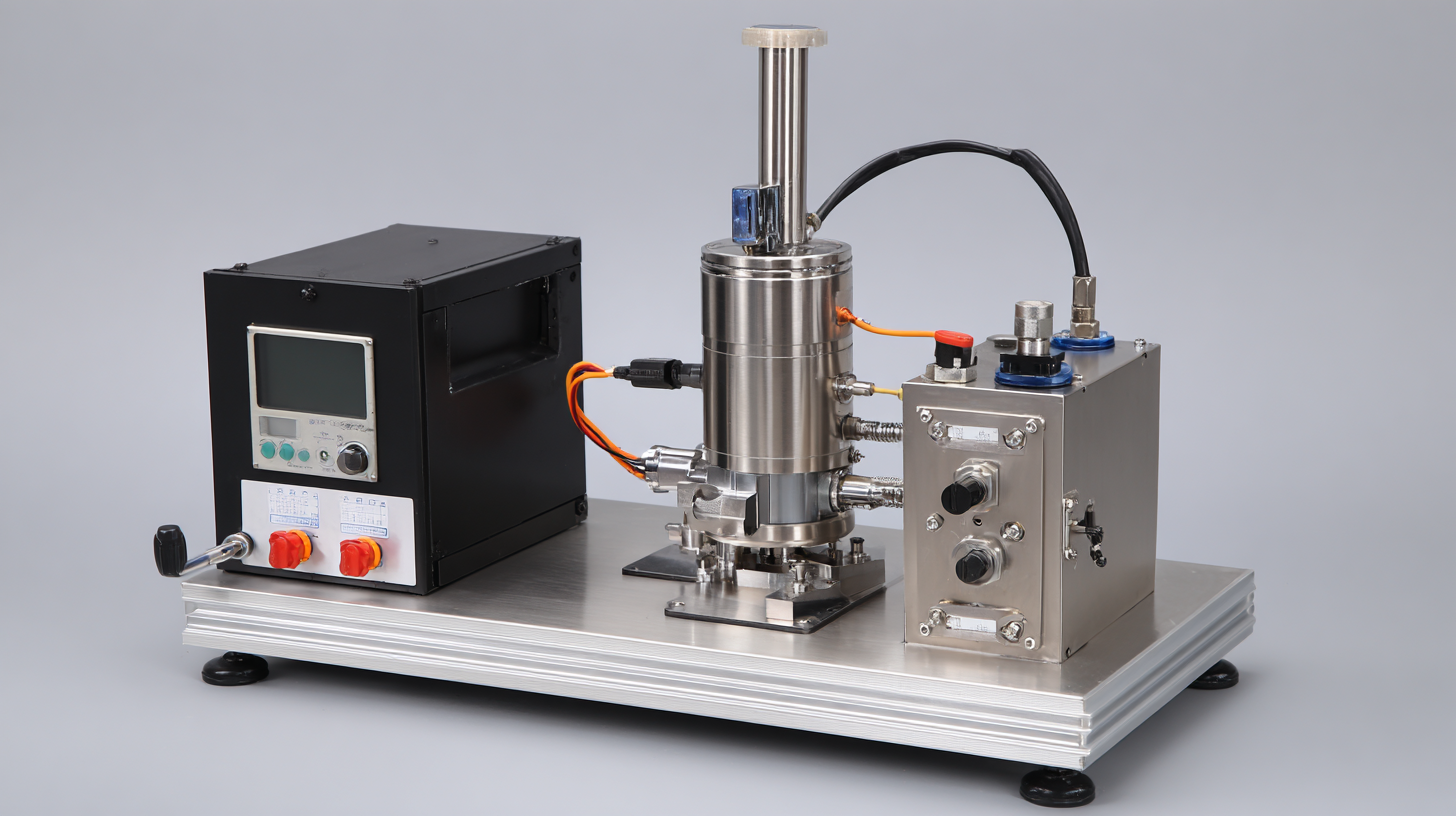

Electric ultrasonic welders are revolutionizing modern manufacturing across various industries, offering robust solutions for joining materials seamlessly. In the automotive sector, these welders are employed to fuse components such as plastic casings and electronic assemblies. The precision and speed of electric ultrasonic welding enhance production efficiency and ensure high-quality outcomes, thereby reducing the likelihood of defective products.

In the medical field, ultrasonic welding is crucial for creating sterile and secure connections in disposable devices, including syringes and IV bags, without compromising their integrity. This application not only maintains the cleanliness required in healthcare products but also supports manufacturers in adhering to stringent regulatory standards.

Electric ultrasonic welders are transforming modern manufacturing by significantly boosting efficiency. Unlike traditional welding methods, electric ultrasonic welding utilizes high-frequency vibrations to join materials, leading to shorter cycle times. This advanced technique minimizes the need for pre-cleaning and post-processing, allowing for rapid production while maintaining high-quality welds. Manufacturers can now produce components faster and more consistently, streamlining their operations and reducing costs.

The implementation of electric ultrasonic welding also enhances precision in joining various materials, especially in industries like electronics, automotive, and medical devices. The ability to control parameters such as pressure and vibration frequency ensures that the welds are not only strong but also meet stringent quality standards. Additionally, this technology reduces the overall energy consumption during the welding process compared to conventional methods. As a result, companies can achieve higher output rates without compromising on the integrity of the products, making electric ultrasonic welders a valuable asset in the drive for operational excellence in manufacturing.

| Benefit Category | Description | Impact on Production | Efficiency Gain (%) |

|---|---|---|---|

| Higher Precision | Electric ultrasonic welders provide consistent and high-precision welding. | Reduction in rework and waste. | 15% |

| Energy Efficiency | Lower energy consumption compared to traditional methods. | Significant cost savings on energy bills. | 20% |

| Faster Production Speeds | Reduced cycle times leading to increased output. | Ability to meet market demand more quickly. | 25% |

| Flexible Welding Options | Capability to weld a variety of materials easily. | Versatility in production applications. | 18% |

| Reduced Material Deformation | Minimized heat impact leads to less material distortion. | Improved part integrity and quality. | 12% |

Electric ultrasonic welders have emerged as a pivotal solution in modern manufacturing, particularly considering their cost-effectiveness and sustainability. Recent studies highlight that the adoption of ultrasonic technology can significantly reduce energy consumption and operational costs compared to traditional welding methods. For example, ultrasonic welding requires lower thermal energy input, which not only results in savings on energy bills but also lessens the environmental footprint of manufacturing processes. As industries strive to meet sustainability goals, electric ultrasonic welding stands out as an ideal approach.

Moreover, the environmental impact of manufacturing processes is gaining increasing scrutiny. The leather industry, for instance, has begun integrating ultrasonic techniques to enhance production efficiency while minimizing waste. Research indicates that sustainable practices, including ultrasonic cutting, can lead to substantial reductions in material waste by optimizing the cutting process, thereby preserving resources and reducing landfill contributions. Initiatives like these are becoming essential as companies seek greener alternatives to conventional methods, aligning with broader trends in sustainability across various sectors. The cost savings associated with reduced operational waste further strengthen the case for adopting electric ultrasonic welders in manufacturing settings.

This bar chart illustrates the key benefits of Electric Ultrasonic Welders in modern manufacturing, highlighting their cost savings, energy efficiency, production speed, waste reduction, and material compatibility. Each metric is represented as a percentage to showcase the effectiveness of these welders in enhancing manufacturing processes.

Electric ultrasonic welding has revolutionized manufacturing processes by offering several advantages over traditional welding methods. One key benefit is the ability to achieve high-quality welds with minimal thermal distortion. Since ultrasonic welding relies on high-frequency vibrations to join materials, it significantly reduces the heat-affected zone compared to conventional welding techniques, thus preserving the integrity of heat-sensitive components.

Moreover, the efficiency of electric ultrasonic welders stands out in high-volume production settings. These machines operate quickly, often completing welding in a matter of seconds, which enhances throughput and lowers operating costs. This time efficiency, combined with reduced energy consumption, positions ultrasonic welding as a sustainable alternative. In contrast, traditional welding methods typically require longer processing times and more energy, potentially leading to greater operational expenses and environmental impact.

In terms of versatility, ultrasonic welding is effective on a wide range of materials and is particularly advantageous for joining plastics and dissimilar materials, which can be more challenging with conventional techniques. The adoption of electric ultrasonic welders not only optimizes manufacturing efficiency but also supports the ongoing shift toward greener and more sustainable production practices in modern industries.