Leave Your Message

As we look towards 2025, the ultrasonic battery welder market is poised for significant growth, driven by the increasing demand for efficient and reliable battery manufacturing processes. According to a recent industry report by Market Research Future, the global ultrasonic welding market is expected to reach approximately $4 billion by 2025, growing at a CAGR of 7.5%. This surge is largely attributed to advancements in electric vehicle production and renewable energy storage solutions, where ultrasonic battery welders play a critical role in ensuring optimal performance and safety. In this blog, we will explore the best applications of ultrasonic battery welders and provide a comprehensive purchasing guide, helping manufacturers make informed decisions for their future needs in this rapidly evolving sector.

Ultrasonic battery welding technology has emerged as a pivotal innovation in manufacturing high-performance battery packs, particularly in electric vehicles. Focusing on key technical specifications for optimal performance, it's essential to understand the parameters that influence the quality of the ultrasonic welds. Recent studies have highlighted the importance of welding width and its direct impact on joint strength and electrical conductivity. By utilizing different welding widths for various copper cable specifications, researchers have demonstrated the ability to optimize welding conditions, ensuring robust connections that withstand thermal shocks.

Additionally, ultrasonic welding allows for effective bonding between multi-layer battery foils and tabs, enabling manufacturers to achieve high-strength joints with great efficiency. The process not only conserves energy but also minimizes material waste, making it a sustainable choice in battery production.

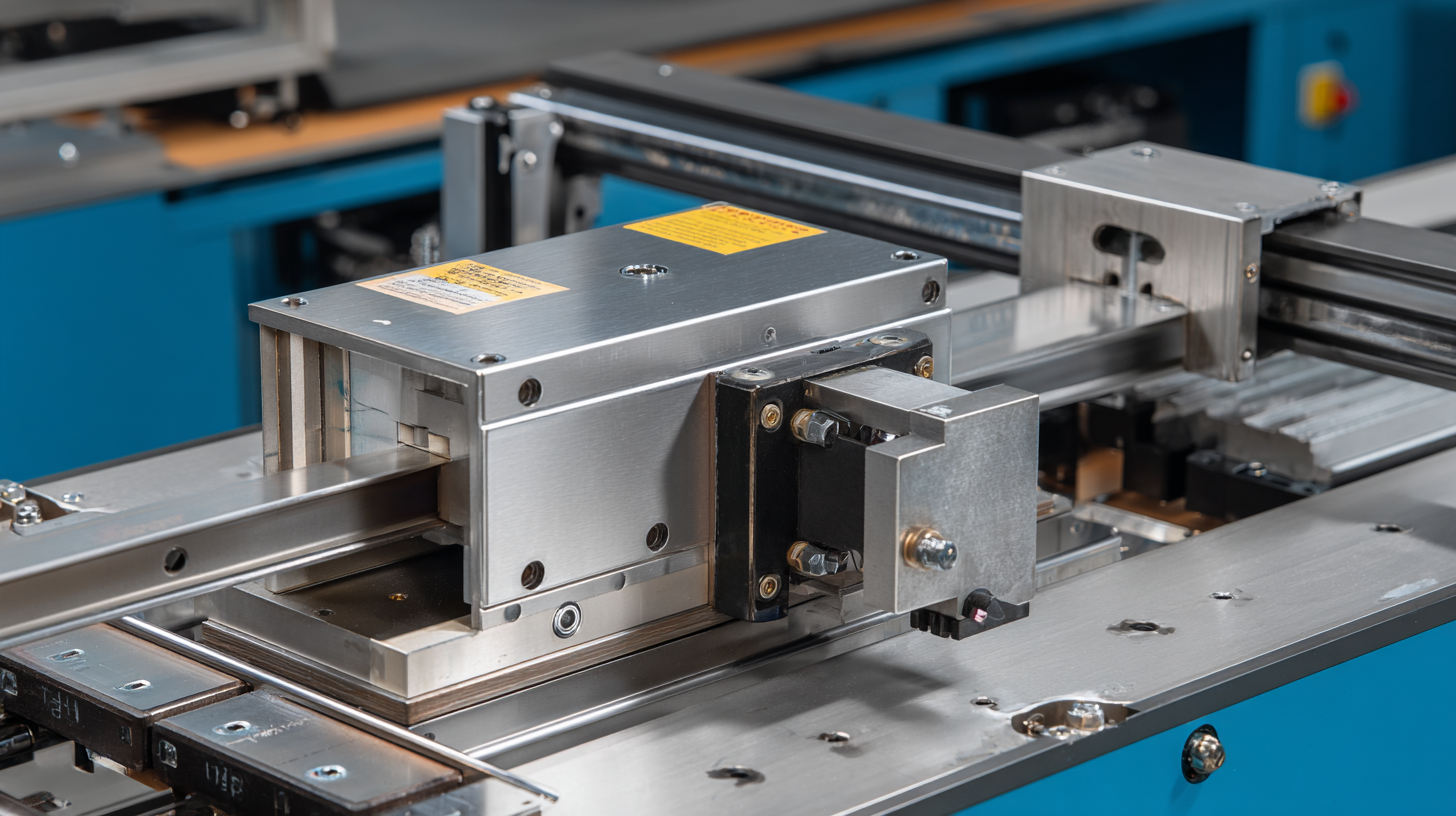

Experimental setups have shown the effectiveness of ultrasonic metal welding in joining different materials, such as aluminum alloys and carbon fiber reinforced polymers. As advancements in ultrasonic welding continue, manufacturers can expect improved reliability and performance in battery technology, paving the way for the next generation of electric vehicles.

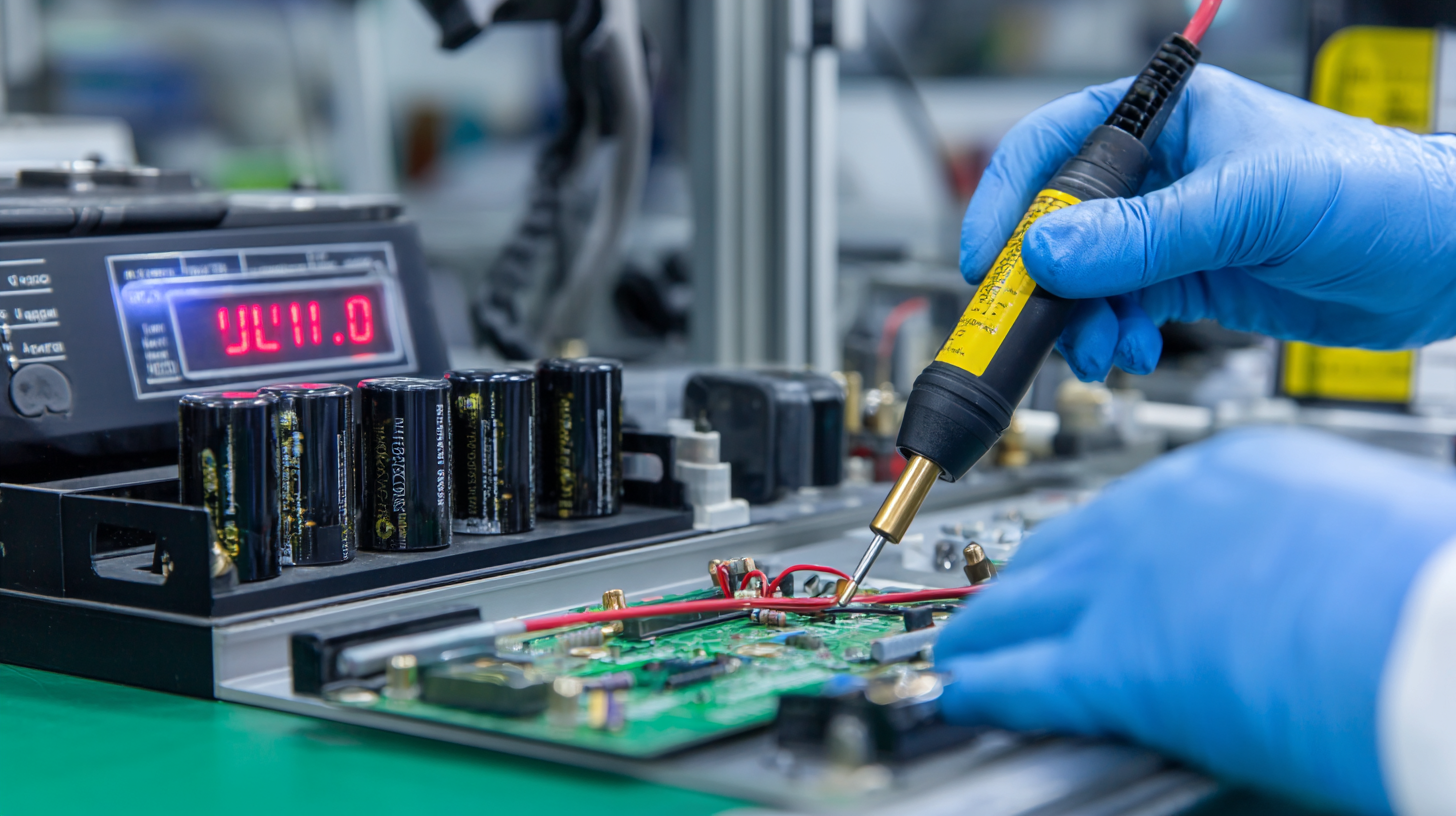

Ultrasonic welding has emerged as a critical technology in battery manufacturing and assembly, particularly for electric vehicles (EVs). This method offers a range of essential applications, primarily in the joining of various battery components, such as nickel tabs to aluminum casings in cylindrical lithium-ion cells. The precision and efficiency provided by ultrasonic welding significantly enhance the electrochemical performance of batteries, ensuring that manufacturers can meet the growing demands for improved capacity and longevity.

Recent innovations in ultrasonic welding tools are further driving advancements in battery production. For instance, developments at universities and companies have introduced benchtop tools that utilize ultrasound technology to not only weld but also test battery integrity. This dual functionality aids automakers in streamlining their manufacturing processes while ensuring high-quality outputs. As the industry shifts towards better-performing batteries, the integration of ultrasonic welding techniques in production lines is expected to play a pivotal role in achieving these goals while addressing challenges related to high volume and efficiency in EV battery assembly.

Operating ultrasonic battery welders effectively requires understanding both the technology itself and best practices. According to a recent market analysis by Industry Research, the global ultrasonic welding market is projected to exceed $7 billion by 2025, highlighting the growing importance of proficient use in battery assembly. Ultrasonic welders are crucial in ensuring strong, consistent bonds in battery production, particularly as the demand for advanced battery technologies escalates.

To operate an ultrasonic battery welder effectively, begin with thorough preparation. Ensure that the welder’s amplitude, frequency, and pressure settings are calibrated according to the material specifications. Consistent monitoring during the welding process is vital; slight variations can affect joint integrity. Additionally, clean and maintain your welding tips regularly to avoid contamination that can compromise weld quality.

Tips: Always conduct preliminary tests with scrap materials to fine-tune your settings before applying them to production units. Continuous training and staying informed about industry best practices can significantly enhance operator efficiency and product reliability. Moreover, keeping an eye on emerging technologies in ultrasonic welding can provide a competitive edge as the market evolves.

When considering the purchase of ultrasonic battery welding equipment, several key factors must be evaluated to ensure optimal performance and cost-effectiveness. According to a report by MarketsandMarkets, the ultrasonic welding market is projected to reach $1.1 billion by 2025, with increasing applications in the automotive and electronics sectors driving this growth. Buyers should prioritize equipment that meets the specific requirements of their battery manufacturing processes, including weld strength, speed, and energy efficiency.

Moreover, the choice of an ultrasonic welder should be influenced by the materials being processed. Materials such as lithium-ion and nickel-metal hydride have different welding parameters, and a system that can adapt to these variations is crucial. A study published by the Journal of Materials Processing Technology highlights that adherence to proper welding techniques can improve joint quality by up to 30%, emphasizing the importance of selecting a machine with precise control features. Additionally, considerations like after-sales support, warranty, and availability of spare parts can significantly impact the long-term operational efficiency of the welding equipment. As the industry evolves, ensuring that the ultrasonic welding equipment is not only technologically advanced but also backed by strong support systems will be essential for manufacturers looking to stay competitive.

The advancements in ultrasonic welding technology are set to significantly enhance battery production processes, particularly in the wake of evolving market dynamics and technological innovations. As seen in recent reports, the lithium-ion battery industry is experiencing a robust growth trajectory, with substantial capital investments expected to drive efficiency and safety in battery manufacturing. The analysis of various battery architectures highlights the demand for lightweight and cost-effective materials, positioning ultrasonic welding as a critical technology for the assembly of next-generation batteries.

Recent research indicates that the composite current collector sector is on the verge of a comprehensive breakout, with lithium battery current collectors trending towards thinner, low-cost, and high-safety designs. The shift towards these advanced materials necessitates precise welding techniques, where ultrasonic welding excels by offering rapid processing times and minimal thermal impact on sensitive battery components. As the industry anticipates significant growth, integrating ultrasonic welding into production lines could provide manufacturers with a competitive edge by ensuring high-quality assembly that meets the escalating safety standards and performance demands of modern batteries.