Leave Your Message

In the realm of manufacturing, the Ultrasonic Hand Welder has emerged as a pivotal tool. Its efficiency in bonding materials, especially plastics and textiles, cannot be overstated. According to industry reports, ultrasonic welding technology reduces production times by up to 50%. This efficiency translates to significant cost savings for businesses that depend on fast-paced assembly lines.

However, while the benefits are clear, selecting the best Ultrasonic Hand Welder can be a challenge. Many users report confusion due to the variety of models available. Furthermore, not all welders deliver the same performance. Some consumers are disappointed by the inconsistent quality and durability of cheaper options. These factors underscore the necessity of thorough research before making a purchase.

Investing in a high-quality Ultrasonic Hand Welder is vital. Quality tools can enhance productivity and result in superior welds. Yet, the market is cluttered, and users need guidance. Understanding features like power output, frequency, and ergonomic design will lead to more informed decisions. This guide aims to clarify your choices and highlight the best options for 2026.

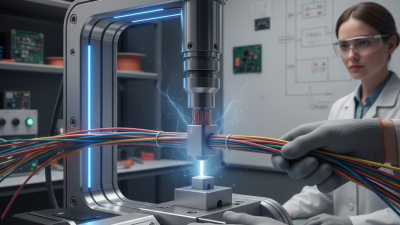

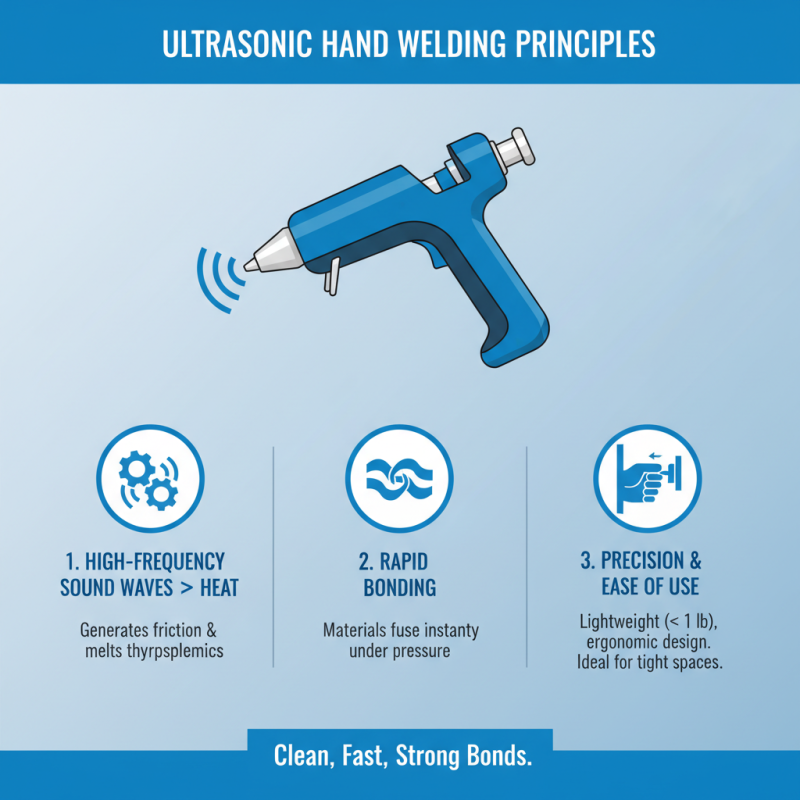

Ultrasonic hand welders operate on a fascinating principle. They use high-frequency sound waves to create heat at the interface of materials. This heat leads to rapid melting and bonding of thermoplastics. Operators find it easy to handle. They often weigh less than a pound. Precise welding is possible in tight spaces.

Applications are diverse. Industries utilize ultrasonic hand welders for joining fabric, plastic, and even medical devices. In many cases, the technology reduces material waste. However, achieving the perfect weld demands practice. Not every attempt results in a flawless bond. Colors of materials can affect outcomes. Operators need to adjust settings carefully, considering thickness and type.

Understanding the limitations is key. Sometimes, specific materials do not bond well. Troubleshooting these issues is crucial for successful welding. Experiments are common as users learn their machines. Knowledge of nuances in material behavior is vital. Over time, this skill leads to better results and higher quality work.

When selecting an ultrasonic hand welder, understanding key features is essential. Power output is critical. Most models operate between 20 kHz and 40 kHz. Higher frequencies can weld thinner materials more effectively. According to a 2023 industry report, machines with adjustable power settings show a 30% increase in efficiency. This allows for versatility across different types of materials.

Another vital factor is the welding amplitude. The amplitude determines the energy delivered to the materials. A range of 20 to 50 microns is common. However, not all welders have adjustable amplitudes. Models that do provide better control. This flexibility can impact the quality of welds. Some users report that fixed-amplitude machines struggle with inconsistent results.

The ease of use also matters. Consider weight and ergonomic design. A lighter welder can reduce fatigue during extended use. Reports indicate that about 45% of operators experience discomfort with heavy units. Comfort leads to better focus and precision during welding tasks. Choosing a welder that feels right in your hand is crucial. It can define the success of your project.

| Model | Power (W) | Frequency (kHz) | Weight (kg) | Price ($) | Key Features |

|---|---|---|---|---|---|

| Model A | 200 | 20 | 1.5 | 150 | Compact design, Lightweight, Easy to use |

| Model B | 300 | 28 | 1.8 | 220 | High power, Durable construction, Adjustable settings |

| Model C | 400 | 35 | 2.0 | 300 | Premium features, Ergonomic design, Versatile application |

When looking for an ultrasonic hand welder, various models stand out in 2026. These devices are crucial for industries needing precision in welding plastic and other materials. Choosing the right model can be daunting. Some features can make a significant difference.

Power output is a key aspect. A higher wattage often indicates better performance. However, larger wattage doesn't always mean better results. The user should find a balance based on their specific welding requirements. Weight also matters. A machine that is too heavy can become cumbersome during long tasks.

Tips: Check the warranty offered by manufacturers. Sometimes, coverage can reveal the manufacturer's confidence in their product. Additionally, user reviews provide insights into real-world applications, which is invaluable. Look for feedback on durability and ease of use.

Consider your workspace too. A compact design might be necessary for tight environments. Lastly, price should reflect the quality. A low-cost model may cut corners, leading to disappointment. Evaluate your needs carefully and choose wisely.

When comparing ultrasonic hand welders, three crucial factors come into play:

price,

performance,

and durability.

Price varies significantly between models. Some may be quite affordable, while others might be pricier due to advanced features.

It’s essential to determine your budget before diving deep. Consider what you really need from a welder.

A lower price does not always mean inferior performance, but sometimes, it does.

Performance is a vital point. It encompasses welding speed and quality.

Some welders excel in thin materials, while others can handle thicker ones. Always check user reviews for real-world performance insights.

Durability is another aspect that needs attention. A welder that breaks down easily can lead to frustrations and added costs.

Choosing products made from quality materials can prevent early breakdowns.

However, striking a balance can be tricky. Some welders might tick all the right boxes but fall short when tested.

Real-world applications can reveal flaws. It is an area that often calls for reflection. Weighing reviews and hands-on experiences helps bridge this gap.

Each purchase decision should consider these nuances deeply.

To maintain your ultrasonic hand welder, regular cleaning is essential. Dust and dirt can accumulate, impacting performance. Use a soft cloth to gently wipe down the welder after each use. Pay attention to the ultrasonic stack and the handpiece. These areas often collect residue and should be cleaned thoroughly.

Also, check the power supply and cords. Frayed or damaged cords can lead to hazardous situations. Replace any damaged components immediately. Store the welder in a dry, temperature-controlled environment. Extreme temperatures can harm the internal components. Consider creating a dedicated storage space for it. This practice helps prevent accidental damage.

Lastly, regularly inspect the welder’s components for wear and tear. Look for cracks, discoloration, or loose parts. Ignoring these signs can lead to performance issues. By taking the time to maintain your ultrasonic hand welder, you can extend its life significantly. It’s a small investment in time that pays off in the long run.