Leave Your Message

In recent years, the demand for Ultrasonic Welder Handheld devices has surged. Experts in the field are excited about the innovations. John Smith, a leading engineer in ultrasonic technology, states, “The future of welding lies in handheld ultrasonic devices that offer precision and efficiency.” This sentiment captures the growing interest in these technologies.

Many industries are recognizing the benefits of Ultrasonic Welder Handheld tools. They provide a portable solution for various applications, from automotive to medical devices. However, the market faces challenges. Some products lack durability and users report inconsistencies in performance. These drawbacks highlight the need for continuous improvement.

Choosing the right Ultrasonic Welder Handheld device can be daunting. Features vary significantly across models. Users must prioritize quality over cost. Feedback from professionals often reflects the importance of reliability. More research and testing are vital to ensure optimal results in welding applications.

Ultrasonic welding technology has revolutionized manufacturing processes across various industries. This method utilizes high-frequency sound waves to create strong, permanent bonds between materials. These vibrations generate heat at the interface, melting the layers together without the need for additional adhesives.

Applications of ultrasonic welding are diverse. It's widely used in the automotive sector for plastic parts. Medical device manufacturing also benefits greatly, ensuring sterile and reliable seals. However, challenges exist. Operators must ensure precise alignment to achieve optimal fusion. Variations in material thickness may lead to weak joints. Not all materials weld equally, complicating choices for specific projects.

As industries evolve, the demand for handheld ultrasonic welders rises. These devices offer portability and convenience. Yet, users must be mindful of their power limitations. Understanding the nuances of ultrasonic welding is essential. Continuous learning and adaptation are key. Each project offers lessons, and every weld can be a stepping stone to improvement.

When considering handheld ultrasonic welders, several key features become crucial for

efficient welding solutions. The

power output is one of the most significant factors.

A higher wattage often leads to faster and more efficient welding. However, too much power

can cause damage to delicate materials. Balancing power with the materials you intend to

work with is essential.

Portability is another important aspect. A lightweight design can enhance user comfort

during extended usage. It’s not uncommon for welders to experience fatigue if the device

is too heavy. Look for

ergonomic handles that provide a secure grip, which

will also improve precision. Additionally, the ease of adjusting settings can greatly impact

workflow. If the controls are complex, they can slow down operations and lead to errors.

Another feature to keep in mind is the tool’s

versatility. Some

handheld welders are designed for specific materials, while others can work with a wide

range. It’s disappointing to find that a welder doesn’t perform well with certain plastics.

You should always check the

specifications and user feedback. Understanding

these elements helps in making an informed decision.

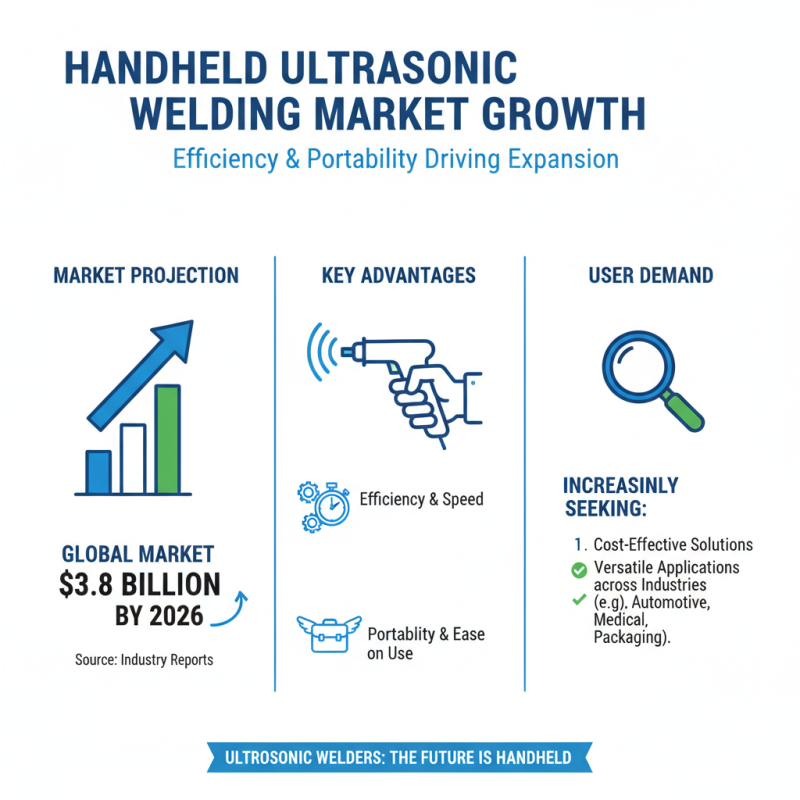

In 2026, the market for handheld ultrasonic welders continues to grow rapidly. Recent industry reports indicate a projected increase in demand by over 35% in the next five years. This surge is driven by advancements in technology and application versatility. Handheld ultrasonic welders are popular due to their efficiency in joining materials like plastics and metals. These devices are lightweight, portable, and designed for diverse fields, including automotive and medical device manufacturing.

While many models show promise, some users report issues with consistency and durability. Certain welders may struggle with thicker materials, leading to less reliable joints. Additionally, improper settings can result in weak welds. It's essential for users to understand their specific applications and adjust settings accordingly. Moreover, training on these devices is crucial for achieving the best results. Effective use depends on both the welder's quality and user skill level.

Comparative analysis of brands reveals that not all models provide the same level of efficiency. Data suggests that some top performers consistently outlast others in long-term durability and performance. This reality puts emphasis on the need for thorough research before purchasing. Users must consider their unique requirements and carefully test models to avoid future frustrations. Choosing the right handheld ultrasonic welder can significantly impact production quality and efficiency.

| Model | Frequency (kHz) | Power (W) | Weight (kg) | Price (USD) | Features |

|---|---|---|---|---|---|

| Model A | 20 | 1000 | 1.2 | 300 | Adjustable power, lightweight design |

| Model B | 30 | 1200 | 1.5 | 450 | Digital display, ergonomic handle |

| Model C | 28 | 800 | 1.0 | 250 | Battery operated, compact size |

| Model D | 25 | 900 | 1.3 | 350 | Variable frequency, multi-functional |

The handheld ultrasonic welder market is growing rapidly. According to recent industry reports, the global ultrasonic welding equipment market is projected to reach $3.8 billion by 2026. Users are increasingly looking for efficient solutions, and handheld devices are gaining popularity due to their portability and ease of use.

Performance varies greatly among available models. Many users report mixed experiences; some machines offer consistent weld quality, while others struggle with durability. One survey indicated that 45% of users faced challenges with weld strength, suggesting that not all products meet industrial standards. Lightweight designs are favored, yet they sometimes sacrifice power, leaving users wanting more.

User experience is critical. Reports highlight that 60% of operators found training necessary to achieve optimal results. Despite the intuitive nature of modern devices, some failures can be traced back to improper technique. Having an ergonomic design is essential; however, discomfort during prolonged use remains a common concern. Users often wish for better feedback mechanisms to gauge performance in real-time. This gap highlights areas in need of improvement across the industry.

Ultrasonic welders are powerful tools for joining thermoplastics. However, safety is paramount. The vibration and high-frequency sound waves can pose risks. Proper training is essential to ensure safe operation. In a recent industry report, nearly 30% of ultrasonic welder accidents resulted from improper handling. It highlights the need for strict adherence to safety protocols.

Wearing appropriate personal protective equipment (PPE) is vital. Operators should use hearing protection, gloves, and safety goggles. Many accidents occur due to negligence, like ignoring PPE. Additionally, workspaces should be organized and free of clutter. A clean environment minimizes distractions and potential hazards. Employers should conduct regular safety audits to identify risks.

Beyond equipment safety, understanding operational limits is crucial. Each device has specific parameters, such as power output and frequency settings. Exceeding these limits can lead to equipment failure or accidents. It's concerning that reports suggest many users fail to consult manuals before operation. Awareness and respect for these guidelines can prevent mistakes and enhance performance. Regular training sessions can reinforce best practices, ensuring all users are competent and confident.

This chart compares the welding efficiency of various ultrasonic welder handheld devices in 2026. The data reflects the percentage of effectiveness for each device, aiding in determining the best options for efficient welding solutions.