Leave Your Message

Choosing the right Ultrasonic Fabric Welder can be a daunting task. With a plethora of options available, it’s important to identify what fits your specific needs. Different industries may require unique features, so understanding these can save you time and effort.

When selecting an Ultrasonic Fabric Welder, consider the materials you will be working with. Some welders excel with certain fabrics, while others might struggle. This could lead to wasted materials or unsatisfactory results. Pay attention to the specifications that matter most to you.

Not every Ultrasonic Fabric Welder will be perfect for your application. There are trade-offs to consider. A higher price doesn’t always mean better performance. Research and test different welders. Learn from feedback and review your choices carefully to ensure the best fit for your requirements.

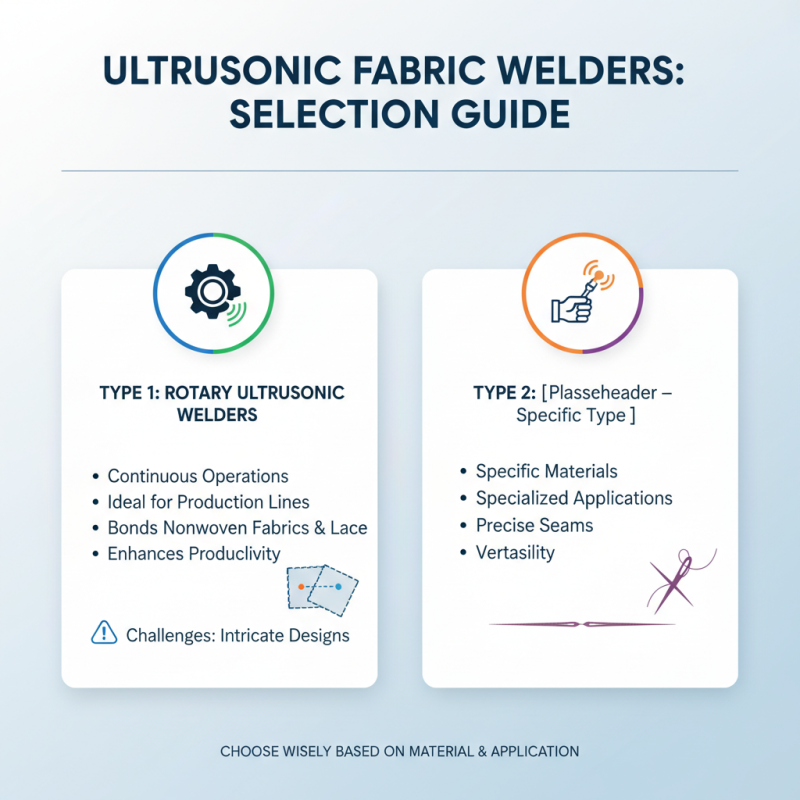

When selecting an ultrasonic fabric welder, understanding the various types available is crucial. Different machines cater to different materials and applications. For instance, rotary ultrasonic welders are ideal for continuous operations, especially in production settings. They efficiently bond materials like nonwoven fabrics and lace. This can enhance productivity but might pose challenges with intricate designs.

Another popular option is bench-top ultrasonic welders. These machines are versatile and suitable for small batches. They’re easier to set up and use. However, their limitations arise in larger scale operations. Users may notice that they can struggle with thicker materials. Spot ultrasonic welders offer precise applications for small areas. They can be advantageous for detailed work, but their efficiency in speed may not meet fast-paced demands.

Making the right choice involves assessing your specific needs. Consider the materials you work with and the desired production speed. Reflecting on these factors is crucial. Each type of ultrasonic fabric welder has its advantages and drawbacks. Understanding your unique requirements helps in making an informed decision.

Choosing the right ultrasonic fabric welder is crucial for your projects. You need to consider several factors carefully. First, assess the material types you will work with. Different materials require different welding settings. This affects the welder’s frequency and amplitude. For example, lightweight fabrics may need less power than heavy-duty materials.

Think about the size of your projects. A compact welder might suffice for small items, but larger projects may require a more substantial machine. Power supply is another important aspect. Verify if the welder suits your electrical setup. It’s an obvious detail but often overlooked.

Consider your budget, too. Be aware that a lower price may mean fewer features or lower quality. Test the machine if possible. Pay attention to its ease of use. Can you adjust settings seamlessly? Reflect on these aspects as they will impact your workflow. Ultimately, find a balance between cost and functionality that fits your specific needs. Every project demands different requirements, so acknowledge that perfection may not always be possible in your selection process.

Choosing the right ultrasonic fabric welder is essential for various applications, from clothing to medical textiles. Key features can significantly impact your decision. Look for machines with adjustable frequency settings. This allows flexibility for different fabric types. A welder with a high power output can effectively bond thicker materials.

Tip: When assessing power levels, consider the types of fabrics you frequently use. Some welders may struggle with certain materials.

Another important feature is the weld speed. Faster weld speeds can increase production efficiency. However, sometimes faster isn’t better. If the weld is not strong enough, it can lead to product failures.

Tip: Run tests on different speeds before settling on a setting. Evaluate the strength of each weld. It’s a detail that can save time and resources later.

Lastly, check the ergonomics and ease of use. A welder that is comfortable to operate can reduce fatigue over long working hours. Poor design can lead to mistakes, which may cause delays in your projects. Always prioritize user-friendly options to enhance productivity.

When choosing an ultrasonic fabric welder, understanding your production needs is crucial. Think about your output requirements. How many units do you plan to produce daily?

A low-volume operation needs a different machine than a high-capacity one. Smaller businesses may benefit from compact models, which are versatile yet effective for limited tasks.

Consider the types of fabrics you will be working with.

Some welders excel with specific materials, while others are more universal. It can be challenging to find the right fit. Review the specifications carefully, noting what each model can handle.

Pay attention to features like speed and consistency, as these will impact your production quality. Reflect on how your production might grow in the future.

It’s wise to choose equipment that offers scalability to adapt to changing needs.

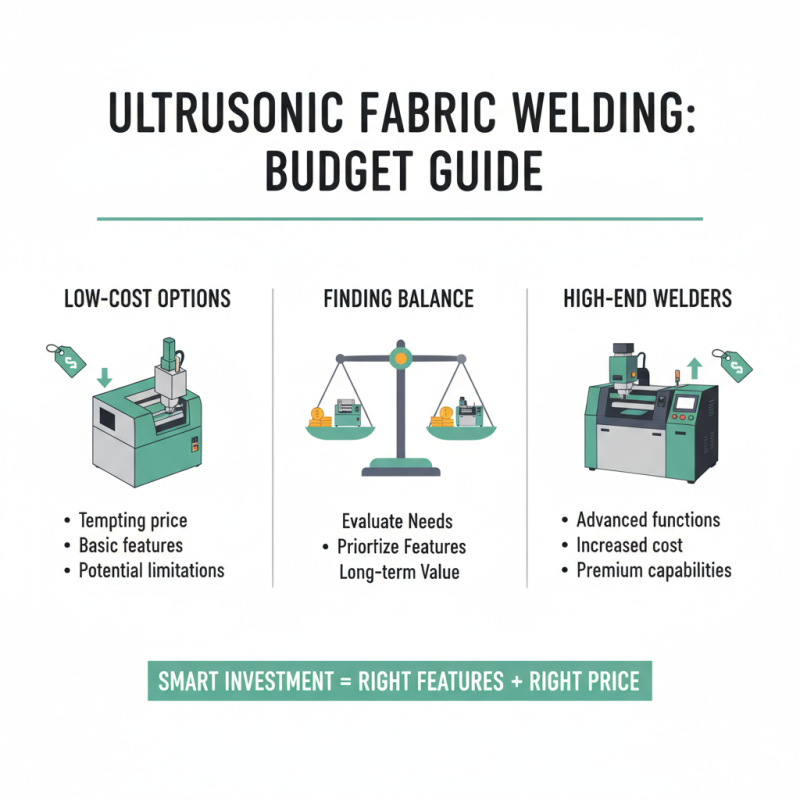

When selecting ultrasonic fabric welding equipment, budget plays a crucial role. Different machines come with various price tags. Low-cost options are tempting but may lack essential features. High-end welders often include advanced functions but can be overwhelmingly expensive. Finding the right balance is key.

Consider your production volume. If it’s low, a budget-friendly model might suffice. However, for larger operations, investing in a better machine can pay off. Don't forget about additional costs. Maintenance, parts, and training can add up quickly. Reflect on your actual needs and avoid overspending on unnecessary features.

Think about future needs too. What if your production demands increase? A slightly more expensive model could offer flexibility. Take the time to evaluate effectively. Visit trade shows or demo sessions to get a feel for different models. This experiential approach lets you see machine capabilities firsthand. Making informed decisions can save you from costly mistakes down the road.