Leave Your Message

Choosing the right ultrasonic welder is essential for ensuring the success of your project, particularly in a market that continues to expand rapidly. According to a recent report by Fortune Business Insights, the global ultrasonic welding market was valued at approximately $2.4 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2022 to 2028. This underscores the importance of selecting a suitable ultrasonic welder for hire, tailored to specific application needs, whether it's in the automotive, medical, or packaging industries. With advancements in technology and increasing demand for automation, understanding the unique features and capabilities of different models becomes crucial. Efficient decision-making not only enhances production quality but also optimizes cost efficiency, making it vital for businesses to discern the best welder suited to their requirements.

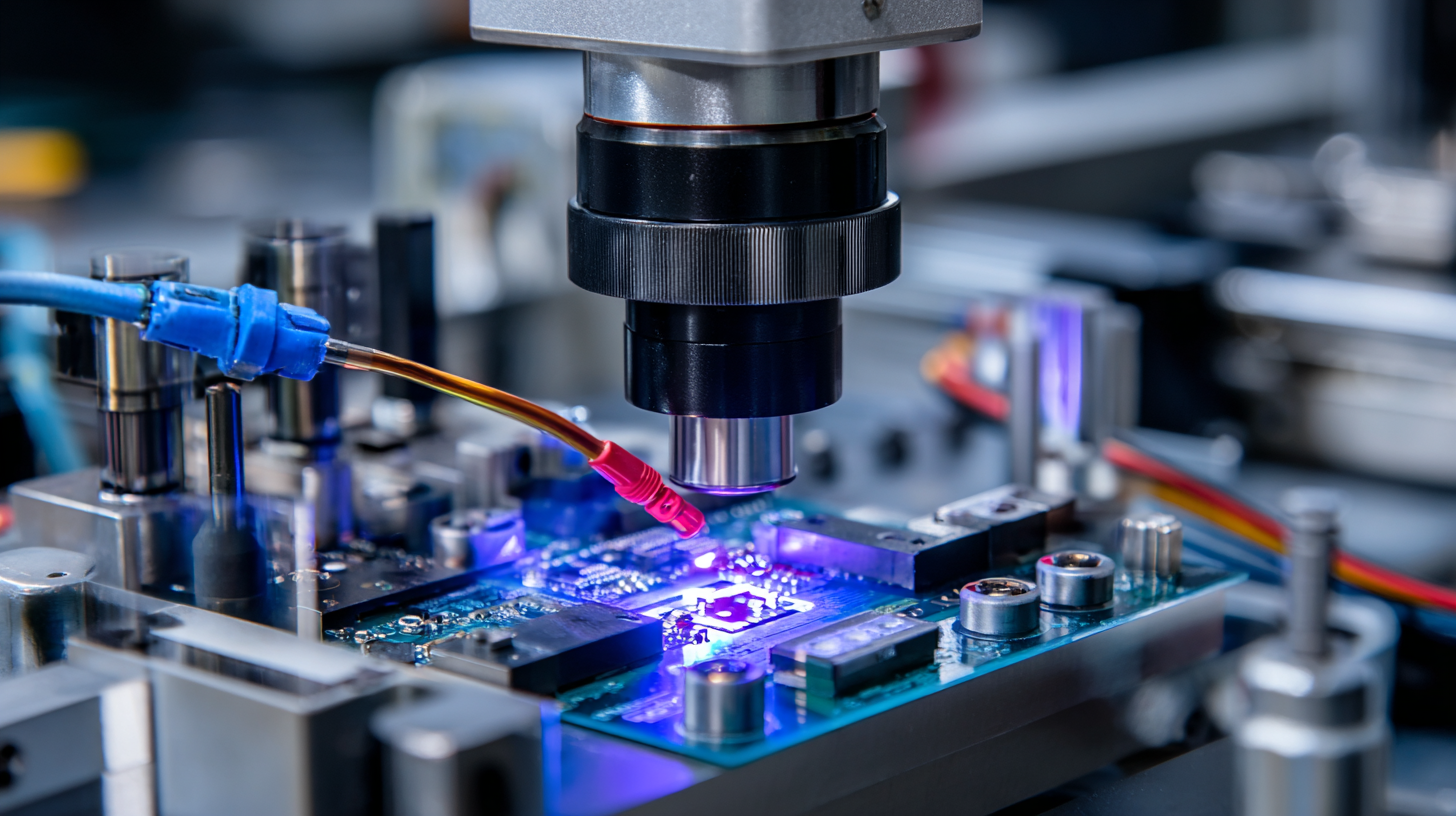

Ultrasonic welding is a versatile joining technology that utilizes high-frequency ultrasonic vibrations to create strong, permanent bonds between plastic or metal components. The fundamental principle lies in converting electrical energy into mechanical vibrations, which are concentrated at the interface of the materials being joined. This process generates localized heat through rapid molecular movement, allowing the materials to melt and fuse without the need for additional adhesives or fillers. Understanding this mechanism is crucial when selecting the appropriate ultrasonic welder for your project.

Applications of ultrasonic welding span various industries, including automotive, electronics, and medical devices, highlighting its adaptability. In the automotive sector, ultrasonic welding is often used for assembling complex plastic components, ensuring robust joints that can withstand high stress. In the electronics industry, it plays a pivotal role in producing connections for wiring and components, where precision and reliability are paramount. Meanwhile, the medical field benefits from the technology's capability to bond bio-compatible materials, facilitating the production of sterile and safe devices. By understanding the key principles and diverse applications of ultrasonic welding, one can make an informed decision when choosing the right welder for specific project needs.

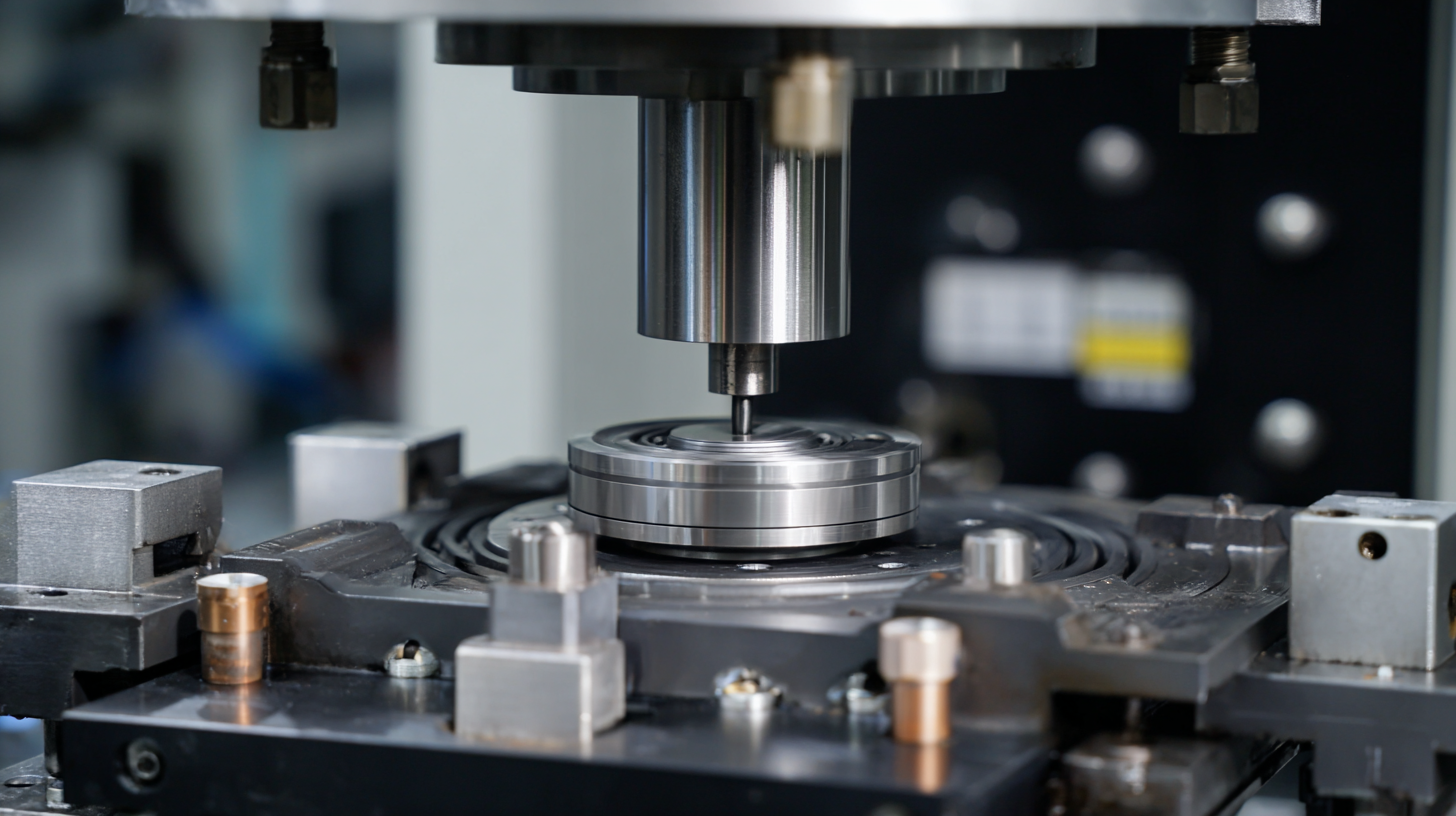

When selecting the right ultrasonic welder for your project, it is crucial to assess your specific requirements, particularly focusing on material types and joint designs. Different materials respond uniquely to ultrasonic welding; for example, thermoplastics, such as polypropylene (PP) and polycarbonate (PC), exhibit excellent bonding capabilities when utilizing ultrasonic techniques. According to a report by Smithers Pira, the global market for ultrasonic welding technology is expected to reach $1.5 billion by 2025, highlighting its growing relevance in various industries.

Tips: Always consider the melting points of the materials you plan to weld. If the materials have significantly different melting points, you might need to experiment with different frequency settings and amplitude levels to achieve optimal results.

Joint design also plays a pivotal role in the success of ultrasonic welding. Overlapping joints provide more surface area for bonding but can compromise the strength of the weld. In contrast, butt joints generally produce stronger welds but require precise alignment. A study by Advanced Materials and Processes indicates that effective joint design can increase weld strength by up to 30%.

Tips: Engage in early-stage prototyping to test different joint designs before full-scale production. This will not only save time but also minimize material waste in the long run.

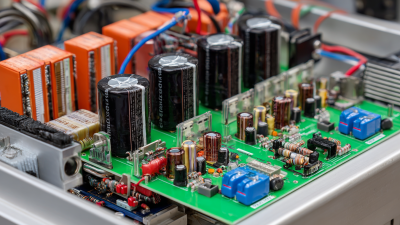

When selecting an ultrasonic welder for your project, understanding power and frequency specifications is crucial for achieving optimal performance. The power output of the ultrasonic welder directly influences its welding capabilities. Higher power levels can deliver more energy to the materials being welded, facilitating the joining process, especially for thicker or more robust materials. However, it's important to match the power with the specific requirements of your application. Too much power can lead to overheating and material damage, while insufficient power may result in weak or incomplete welds.

Frequency specifications also play a vital role in the efficiency of the ultrasonic welding process. Most ultrasonic welders operate within a frequency range of 20 kHz to 70 kHz. Lower frequencies tend to provide greater penetration, making them ideal for bonding thicker materials, whereas higher frequencies are suited for more delicate applications that require precision. When choosing a welder, consider the materials you'll be working with and their thickness, as this will guide you in selecting the appropriate frequency to achieve the most reliable and effective welds. Proper evaluation of both power and frequency can significantly enhance the quality of your ultrasonic welding results.

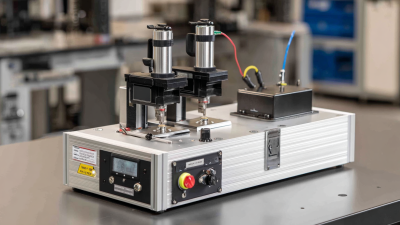

When selecting an ultrasonic welder for your project, focusing on the right features is essential to ensure efficiency and safety. One of the primary considerations is automation. Automated ultrasonic welders can significantly enhance productivity by reducing operator involvement and minimizing human error. With advanced features such as automated cycle control and material handling systems, automated welders can consistently deliver high-quality welds while freeing up valuable labor resources.

Control features are equally important, as they can directly affect the precision and repeatability of the welding process. Look for welders equipped with digital control systems that allow for easy adjustments of parameters like power output, ultrasonic frequency, and weld time. This capability enables operators to fine-tune the device to match specific material characteristics and project requirements. Additionally, consider models with real-time monitoring that can provide feedback during the welding process, ensuring optimal performance and reducing the risk of defects.

Safety measures should never be overlooked when choosing an ultrasonic welder. Opt for machines that incorporate safety features such as emergency stop buttons, protective enclosures, and user-friendly interfaces that minimize the risk of accidents. Furthermore, training for operators on best safety practices is essential to ensure their well-being while handling equipment. By prioritizing these features, you can make an informed decision and achieve successful outcomes for your welding projects.

| Feature | Description | Importance Level | Recommendations |

|---|---|---|---|

| Automation | Integrates robotic systems for increased speed and efficiency. | High | Consider automated systems for production lines. |

| Control Options | Adjustable settings for frequency, amplitude, and time. | Medium | Choose models with user-friendly interfaces. |

| Safety Features | Includes emergency stop, overload protection, and safety interlocks. | High | Select welders with multiple safety measures. |

| Power Supply | Voltage and wattage options that fit your operational needs. | Medium | Ensure compatibility with facility power sources. |

| Portability | Ease of moving the machine to different work areas. | Low | Evaluate if fixed or mobile units are more suitable. |

When considering the purchase of an ultrasonic welder, conducting a cost versus benefit analysis is crucial. This process allows you to evaluate not only the initial investment but also the long-term advantages that the machine can provide for your specific projects. Ultrasonic welders can vary significantly in price based on features, size, and capabilities. Establishing a clear budget helps you to narrow down your options and align your selection with the financial resources available for your project.

On the benefits side, ultrasonic welders can drastically improve production efficiency and the quality of welded joints. They simplify the welding process, reduce cycle times, and often result in less material waste. By understanding the return on investment—such as increased productivity, reduced labor costs, and enhanced product quality—you can justify the expenses associated with choosing a high-quality ultrasonic welder. Ultimately, weighing these factors will guide you in making an informed decision that provides the best value for your budget.