Leave Your Message

In today's fast-paced manufacturing landscape, selecting the appropriate Ultrasonic Welder Machine is crucial for optimizing production efficiency and ensuring product quality. According to a recent industry report by MarketsandMarkets, the ultrasonic welding market is projected to reach $2.1 billion by 2025, growing at a CAGR of 5.9%. This growth is driven by the increasing demand for high-quality and environmentally friendly joining methods across various sectors, including automotive, electronics, and healthcare.

With a myriad of options available, it becomes imperative for businesses to assess their specific needs based on factors such as material compatibility, production volume, and cost-effectiveness. This guide will outline key considerations and expert recommendations to help you choose the most suitable Ultrasonic Welder Machine that aligns with your business objectives and enhances your operational capabilities.

When choosing the right ultrasonic welder machine for your business needs, it's crucial to consider the specific materials and products involved in your applications. According to industry reports, the global lifecycle assessment (LCA) software market is expected to grow significantly, reaching a size of $695.3 million by 2032 from $261.8 million in 2025, with a compound annual growth rate (CAGR) of 15.0%. This growth indicates an increasing emphasis on sustainable practices and materials in manufacturing processes, including the use of ultrasonic welding technology to enhance product durability and efficiency.

Furthermore, the development of self-healing materials is set to revolutionize various industries, as reported by IDTechEx, which provides an in-depth analysis of over 20 application areas, focusing on technology readiness levels (TRL). Manufacturers looking to adopt ultrasonic welding must assess their material choices in the context of these technological advancements. Selecting machines suited to both conventional and innovative materials will not only align with industry standards but also meet the evolving demands of sustainability and product longevity in today's market.

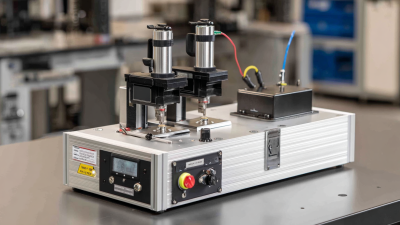

When selecting an ultrasonic welder machine for your business, evaluating the machine specifications is crucial. One of the primary factors to consider is power output. Depending on the materials you plan to work with, different power levels can significantly influence the quality of the weld. For instance, heavier or thicker materials typically require higher power outputs to ensure a strong bond. Therefore, understanding the materials’ characteristics and their welding requirements can guide you in choosing an appropriate level of power.

In addition to power output, frequency is another vital specification. Ultrasonic welding machines operate within specific frequency ranges, commonly between 20 kHz to 70 kHz. The frequency impacts the tautness of the weld and the speed of the welding process. For delicate applications, a higher frequency may be preferred to prevent damage to the components, whereas lower frequencies might be more suitable for heavy-duty applications. Moreover, the size of the machine must align with your workspace and the types of projects you’ll be handling. A compact machine might fit well in smaller facilities, while larger machines could support more extensive production lines. Considering these specifications will help you choose a welder that meets your specific business needs.

| Model | Power Output (Watts) | Frequency (kHz) | Weight (kg) | Size (mm) |

|---|---|---|---|---|

| Model A | 1000 | 20 | 50 | 400 x 300 x 200 |

| Model B | 1500 | 30 | 70 | 500 x 350 x 250 |

| Model C | 2000 | 40 | 90 | 600 x 400 x 300 |

| Model D | 1200 | 25 | 60 | 450 x 320 x 220 |

When selecting an ultrasonic welder machine, businesses often face the challenge of balancing cost and performance. Industry reports indicate that investing in high-quality machines can result in a 20-30% increase in production efficiency, significantly impacting the bottom line. However, the initial cost of these machines can be substantial, often ranging from $5,000 to $50,000 depending on the model and capabilities. It’s essential to analyze the specific application needs, as lower-cost machines may lead to higher operational costs due to increased maintenance and reduced throughput.

**Tips:** To make the most informed decision, conduct a thorough needs assessment to determine the volume and types of materials you’ll be working with. Consulting with vendors who provide detailed specifications and customer testimonials can also illuminate the true value of each option.

Furthermore, consider the long-term implications of your purchase. A less expensive machine might save you money upfront, but can incur hidden costs over time due to inefficiencies. An industry study revealed that firms focusing on quality over initial price typically achieve better ROI, emphasizing the importance of a balanced approach in your procurement strategy.

**Tips:** Always request a demonstration of the machine’s capabilities and performance metrics to ensure it meets your operational requirements before making a purchase.

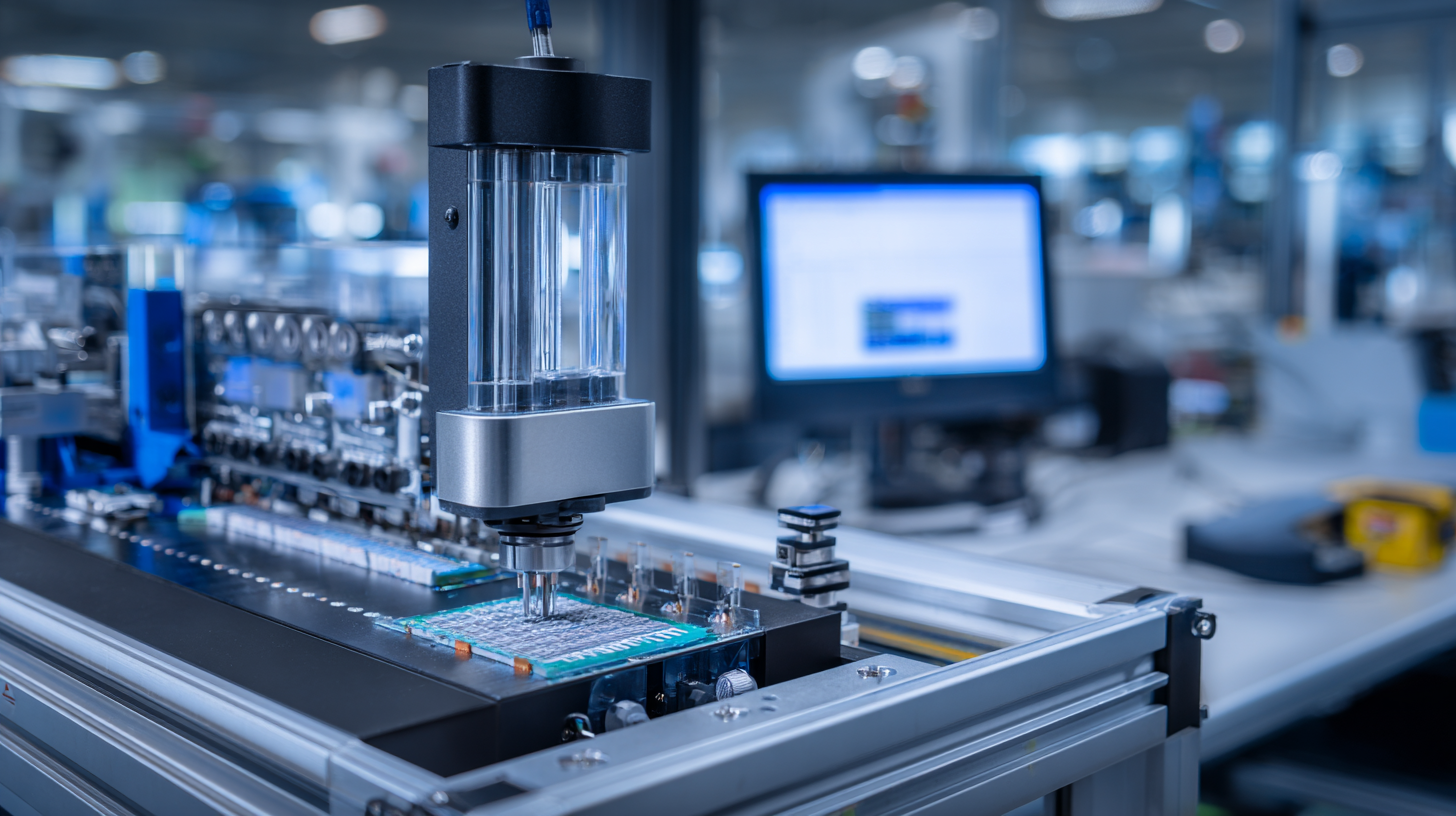

When selecting an ultrasonic welder machine for your business, it is crucial to stay informed about market trends and industry demands that shape equipment choices. Innovations in ultrasonic technology have led to advancements such as automated systems and improved frequency control, which can significantly enhance production efficiency. Businesses must evaluate these developments to ensure they choose machines that align with their operational needs and offer a competitive edge in the market.

Additionally, analyzing industry demand is essential in making an informed decision. Different sectors may require specific functions or capabilities from ultrasonic welders, such as increased power for tougher materials or versatility for various applications. Engaging with market research reports, attending industry trade shows, and collaborating with suppliers can provide valuable insights into which machines best meet current and future demands. By aligning equipment selection with both market trends and industry requirements, businesses can foster growth and innovation in their manufacturing processes.

Choosing the right ultrasonic welder machine for your business is critical to optimizing production efficiency and cost-effectiveness. One way to ensure you make an informed decision is by consulting with industry experts. According to a report by Grand View Research, the ultrasonic welding equipment market is projected to reach $3.3 billion by 2025, demonstrating rapid growth driven by advancements in technology and increasing demand across various industries. Engaging with professionals who have a deep understanding of market trends and technology developments can significantly aid in selecting the right equipment tailored to your specific needs.

Choosing the right ultrasonic welder machine for your business is critical to optimizing production efficiency and cost-effectiveness. One way to ensure you make an informed decision is by consulting with industry experts. According to a report by Grand View Research, the ultrasonic welding equipment market is projected to reach $3.3 billion by 2025, demonstrating rapid growth driven by advancements in technology and increasing demand across various industries. Engaging with professionals who have a deep understanding of market trends and technology developments can significantly aid in selecting the right equipment tailored to your specific needs.

Professional advice allows businesses to leverage the latest data and insights, increasing the likelihood of selecting a machine that meets current and future production requirements. A study by Markets and Markets highlighted that improper equipment selection can lead to inefficiencies costing companies up to 20% of their total production capacity. Experts can provide critical evaluations not only of the machines available but also how they integrate with existing systems. By collaborating with industry specialists, businesses can avoid costly missteps and secure a competitive edge in an evolving market.