Leave Your Message

An Ultrasonic Wire Welder plays a crucial role in modern manufacturing. This innovative tool is essential for creating strong, reliable connections in various applications. However, using it effectively can be challenging.

Understanding the machine's operation is vital. Proper setup and calibration can make a significant difference. Even small misalignments can lead to weak welds. Operators must pay attention to detail. Incorrect settings might cause high rejection rates of finished products.

Investing time in training is often overlooked. Some might assume they can learn through experience alone. This approach can lead to mistakes. Regular practice is necessary for mastering the Ultrasonic Wire Welder. Reflecting on past errors can guide improvements. In the end, effective use combines knowledge, skill, and continuous learning.

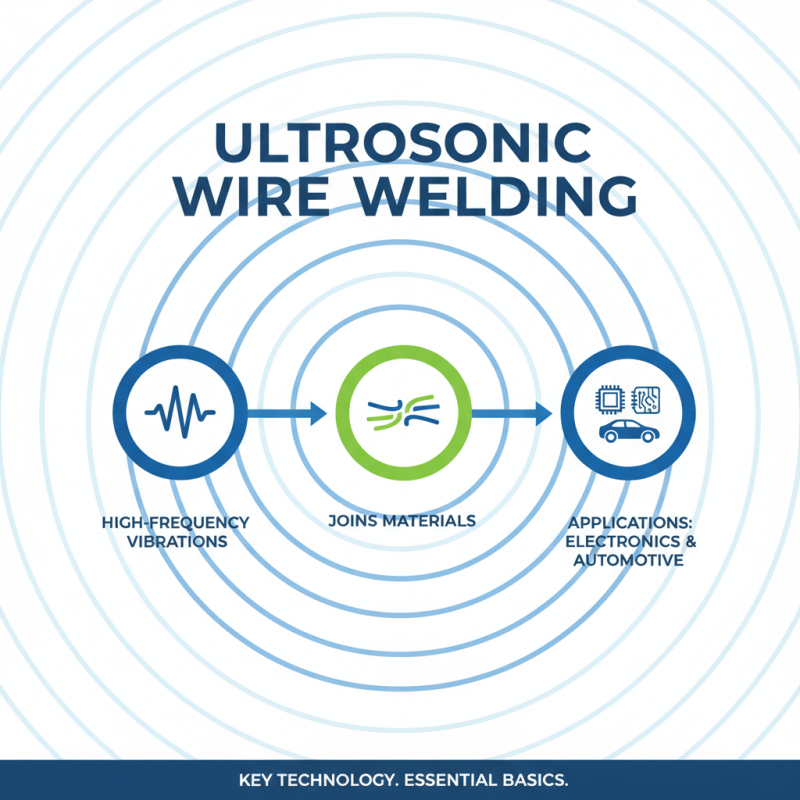

Ultrasonic wire welding is a fascinating technology. It relies on high-frequency vibrations to join materials. This method is used in various industries like electronics and automotive. Understanding the basics is essential for effective use.

The core principle involves generating ultrasonic waves. These waves create a rapid melting effect at the interface of the wires. The process is quick and can be automated, but it requires precision. Improper settings can lead to weak joints. Factors like amplitude, pressure, and frequency must be fine-tuned. Even slight variations can result in failures.

It's important to practice and test different settings. Sometimes results aren't as expected. Observing the output helps identify areas for improvement. Experimenting with different materials can also yield insights. Each project presents unique challenges, demanding continuous learning.

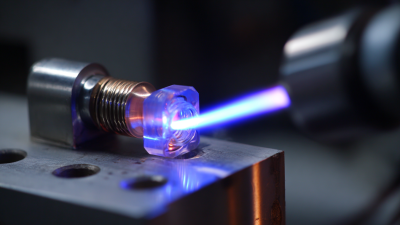

Ultrasonic wire welding is a specialized process, crucial for many applications. This technique requires specific components to function effectively. The ultrasonic generator converts electrical energy into high-frequency mechanical vibrations. This energy is then transmitted to the transducer, which amplifies it. The transducer crucially influences welding quality. If it malfunctions, the welding can fail.

Another key component is the sonotrode. This tool delivers ultrasonic energy to the wire. Its design impacts focus and efficiency. Selecting the right sonotrode material is essential. It must withstand wear and provide durability. Additionally, the anvil supports the workpiece during the welding process. The alignment between the sonotrode and the anvil is critical. Improper alignment leads to ineffective welds.

Proper maintenance of these components is vital. Regular inspections can prevent unexpected breakdowns. Users often overlook small wear and tear. Ignoring these aspects can lead to significant issues. Understanding each component's role can enhance the overall welding process. Fine-tuning parameters is essential for optimizing results. Each piece of equipment requires thoughtful consideration to achieve successful welding.

Setting up an ultrasonic wire welder requires careful attention to detail. Begin by selecting the right workspace.

Make sure the area is clean and well-lit. Organize your tools and materials for easy access. This helps minimize distractions and improves efficiency.

Next, focus on the machine itself. Check all the connections and make sure the ultrasonic generator is properly calibrated.

Take time to read the manufacturer’s guidelines. This ensures you fully understand the machine's capabilities and limitations. Be prepared to troubleshoot any issues. Not all setups go smoothly.

You may face unexpected challenges that require critical thinking.

Once the machine is set up, practice is essential. Start with small test pieces before moving to larger projects.

Monitor the weld quality closely and adjust settings as needed. You'll notice differences in materials and how they respond. Don't hesitate to jot down notes.

Reflecting on what works and what doesn’t can lead to better results in future projects.

Wire welding can be tricky. Operators often face challenges that require quick solutions. One common issue is inconsistent weld quality. This can happen due to improper settings or material variations. Checking the machine settings is crucial. Sometimes, the materials themselves are not compatible. Ensuring the correct wire and materials will save time and effort.

Another challenge is overheating. This may lead to surface damage and weak joints. Monitoring the welding duration helps prevent this. Operators should also maintain a steady pace. Stopping and starting can create additional heat. Additionally, wear and tear of equipment can cause malfunction. Regular inspection and maintenance are vital.

Mistakes happen. It’s part of the learning process. Not every weld will be perfect. Sometimes, even minor adjustments can yield significant improvements. Analyzing past jobs helps identify recurring problems. Keeping a log of these challenges can aid in future projects. Learning from welding experiences enhances skills over time.

| Challenge | Description | Common Causes | Troubleshooting Tips |

|---|---|---|---|

| Inconsistent Weld Quality | Variability in weld strength and appearance. | Incorrect amplitude settings, wire material variation. | Calibrate amplitude, use consistent materials. |

| Sonic Energy Loss | Inefficient energy transmission during the welding process. | Poor contact, worn transducers. | Inspect and replace transducers, ensure proper contact. |

| Overheating | Excessive heat during welding can damage components. | Too high power settings, poor cooling. | Reduce power settings, improve cooling systems. |

| Incomplete Welds | Welding does not fully fuse wire joints. | Insufficient pressure, short welding time. | Increase pressure and ensure adequate welding time. |

| Poor Wire Feed | Wire does not feed consistently into the welder. | Blocked feed mechanism, improper tension. | Clear blockages, adjust feed tension. |

Maintaining your ultrasonic wire welder ensures its efficiency and longevity. Regular cleaning is essential. Dust and debris can hinder performance. Use a soft cloth to wipe surfaces regularly. Pay attention to the transducer and sonotrode areas. These spots accumulate residue quickly and impact weld quality.

Check the ultrasonic generator settings frequently. Ensure that output power is consistent. Fluctuations can cause weak welds or equipment damage. Inspect the wiring connections routinely as well. Loose or damaged wires can lead to performance issues. Replacement may seem trivial, but neglect can lead to bigger problems down the road.

Calibration is another crucial aspect. Misalignment can result in poor welds. Regularly calibrate your equipment to maintain precision. Keep a maintenance log. Note any irregularities to identify patterns over time. Reflecting on past issues helps prevent future mistakes. Embrace a proactive approach for better results.