Leave Your Message

Ultrasonic welding has emerged as a crucial technology in the plastic bonding industry, offering significant advantages over traditional joining methods. According to a report by MarketsandMarkets, the global ultrasonic welding market is projected to reach USD 2.77 billion by 2025, driven by the increasing demand for efficient and high-quality plastic bonding solutions across various sectors, including automotive, consumer goods, and electronics. The efficiency of ultrasonic welders in plastic applications lies in their ability to create strong, reliable joints with minimal thermal damage, thereby preserving the integrity of the materials being joined. Moreover, the process can be completed in a fraction of a second, significantly improving production rates and reducing operational costs. As manufacturers continue to prioritize speed and quality in their production lines, integrating advanced ultrasonic welding techniques into plastic bonding processes stands as a vital strategy for enhancing overall operational efficiency.

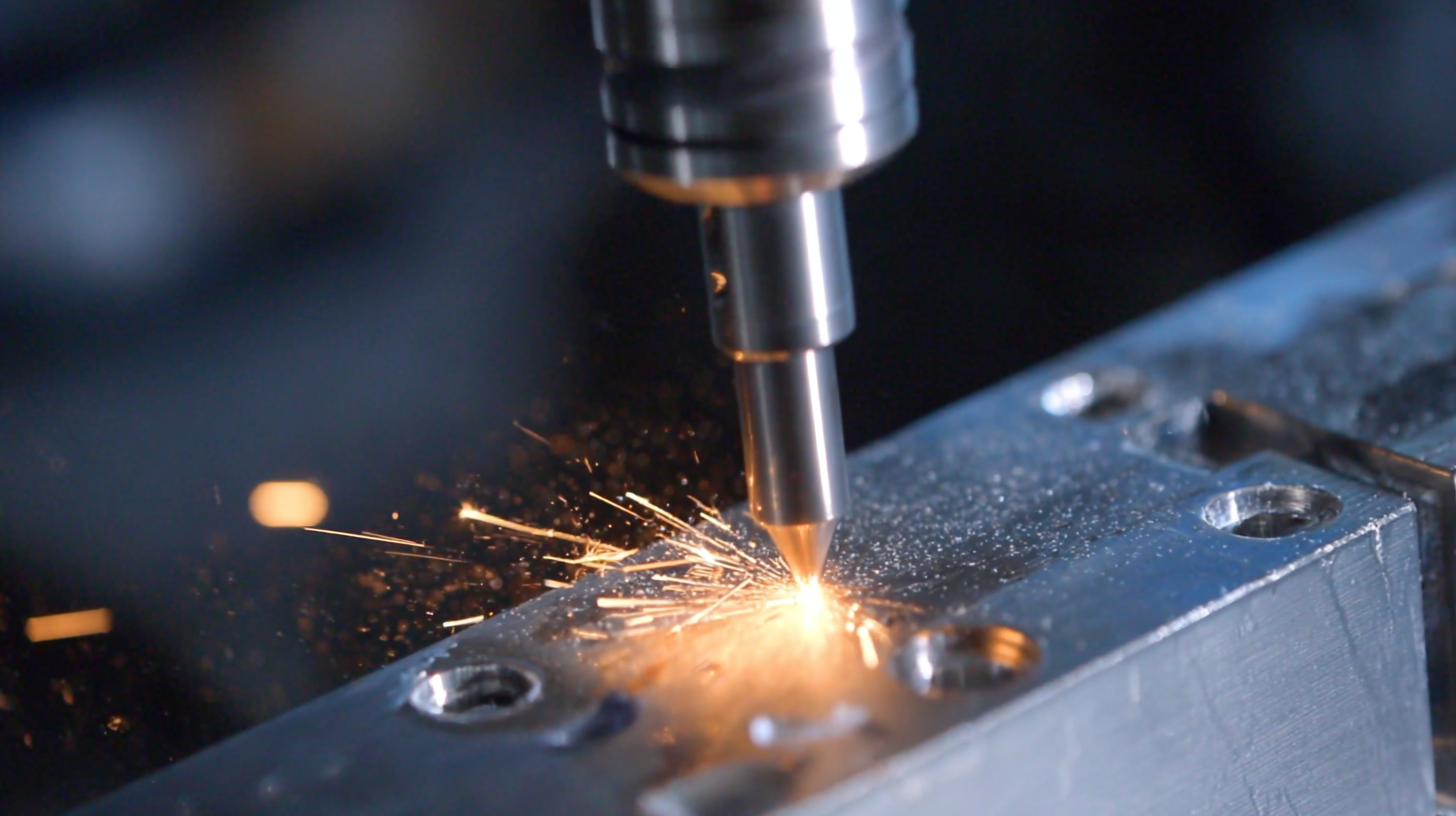

Ultrasonic welding has become a pivotal technique in enhancing the efficiency of plastic bonding processes. Understanding the basics of this technology allows manufacturers to leverage its capabilities effectively. At its core, ultrasonic welding involves the use of high-frequency sound waves to generate heat through mechanical vibrations at the interface of the plastic materials being joined. This localized heating melts the plastic, allowing for a strong bond to form as the materials cool and solidify.

One essential tip for optimizing ultrasonic welding is to ensure proper alignment of the parts being bonded. Misalignment can lead to uneven stress distribution and weak joints. Additionally, maintaining the appropriate pressure during the welding process is critical. Excessive pressure can cause material deformation, while insufficient pressure may result in inadequate bonding.

Another tip is to select the right ultrasonic welding equipment based on the specific type of plastic and joint design being used. Different materials have varying acoustic properties that can affect the welding process. By understanding the unique characteristics of the plastic and the parameters of the ultrasonic equipment, manufacturers can achieve better bonding efficiency and overall product quality.

| Parameters | Description | Impact on Bonding |

|---|---|---|

| Frequency | The number of cycles per second of the ultrasonic wave. | Higher frequencies can lead to finer bonding details and reduced thermal impact. |

| Amplitude | The maximum displacement of the ultrasonic wave. | Optimal amplitude improves the effectiveness of the energy transfer, enhancing bond strength. |

| Pressure | The force applied to the materials being welded. | Increased pressure ensures better material contact, leading to improved bond quality. |

| Welding Time | Duration of ultrasonic energy application. | Adequate time ensures sufficient heat generation at the bond interface for effective welding. |

| Material Compatibility | The ability of different plastics to bond together. | Compatible materials bond more effectively and provide stronger joints. |

Ultrasonic welding has become a prominent technique for enhancing plastic bonding efficiency, particularly in the automotive and electronics industries. Various factors significantly influence the efficiency of the ultrasonic welding process in plastics. One crucial aspect is the

material compatibility; different plastics have varying melting points and ultrasonic absorption characteristics. Selecting compatible materials ensures optimal energy transmission, leading to efficient bonding.

Another key factor is the frequency and amplitude of the ultrasonic waves. Higher frequencies can result in finer welds but may require specific adjustments to ensure thorough melting and bonding. Proper calibration of the welding parameters, including time and pressure, is also essential to prevent defects.

Tips: Always test your welding settings on similar plastic samples before full production to find the ideal parameters. Consider the use of ultrasonic boosters to enhance energy concentration at the weld interface, improving overall bond strength. Regular maintenance of the ultrasonic welding equipment ensures consistent performance and longevity, reducing downtime and improving efficiency.

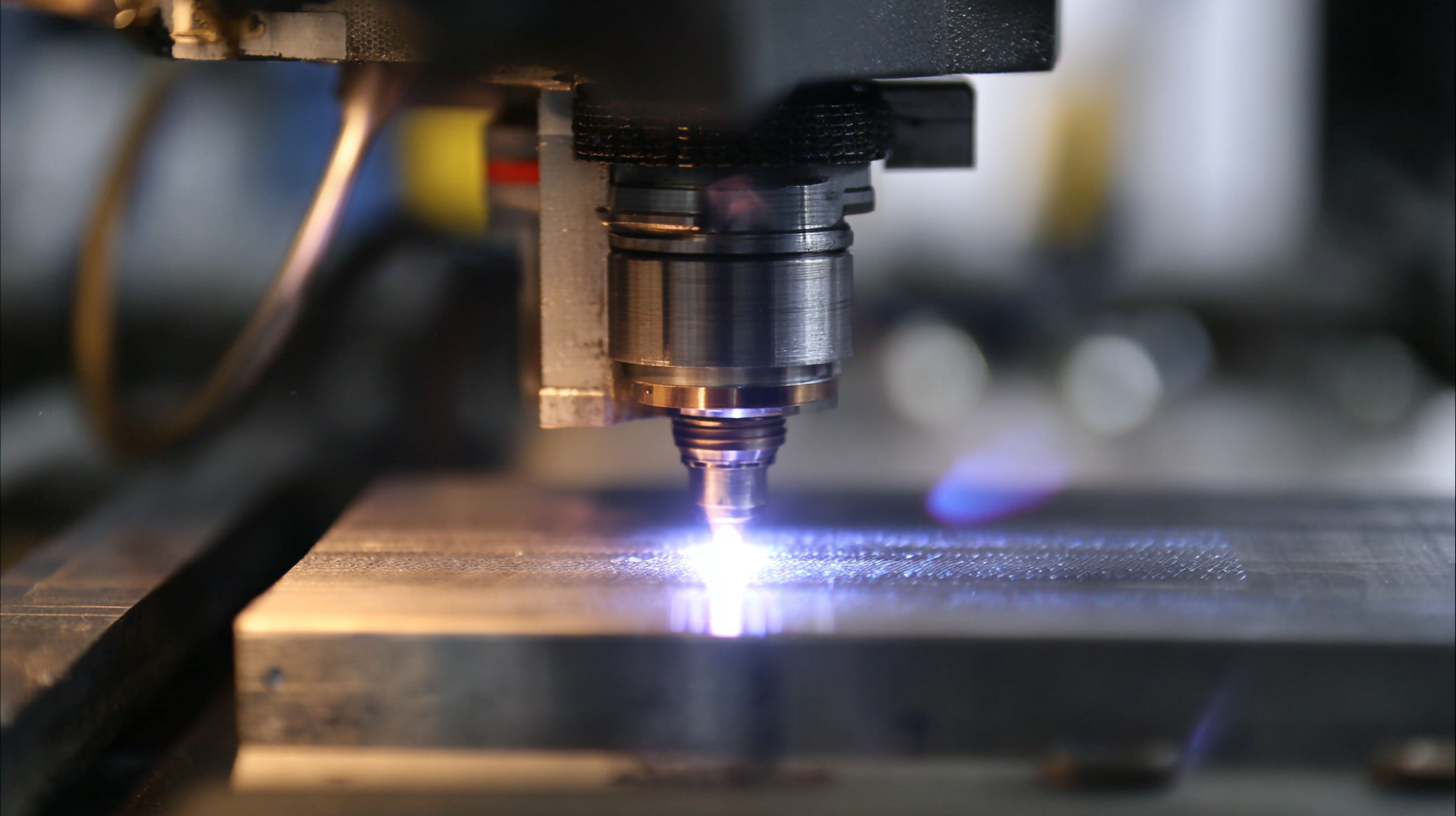

Innovative techniques for optimizing ultrasonic welding parameters are crucial for enhancing bonding efficiency, particularly in applications such as automotive electrical systems. Recent research emphasizes the importance of fine-tuning ultrasonic welding settings to improve wire terminations, which are essential for ensuring electrical connectivity and reliability. By focusing on factors such as pulse duration, energy input, and pressure, manufacturers can significantly enhance the strength and integrity of welded joints.

Furthermore, advancements in ultrasonic welding technology continue to address the challenges associated with assembling small plastic parts in various industries. Enhanced platforms are now capable of meeting the stringent demands for precision and quality in medical and automotive applications. Optimizing these parameters not only improves the weld quality but also contributes to the overall performance and durability of the assembled components. Techniques such as adjusting amplitude and frequency further demonstrate the potential for significant improvements in the efficiency and effectiveness of ultrasonic welding processes.

Plastic bonding presents several challenges, particularly in achieving strong, reliable joints under varying conditions. A significant concern is the potential for inconsistencies in material properties, which can lead to weak seams. According to a report by the Society of Plastics Engineers, inconsistencies in polymer compositions can decrease the bonding strength by up to 30%, resulting in higher rejection rates in manufacturing processes. Moreover, surface contamination, including oils and dust, can further compromise bond integrity, making it crucial to ensure cleanliness prior to welding.

Ultrasonic welding techniques provide effective solutions to these challenges by utilizing high-frequency vibrations to generate localized heat at the joint interface. This method not only enhances the melting and fusion of thermoplastics but also mitigates the problems caused by contaminants. Research indicates that ultrasonic welding can achieve bond strengths exceeding 90% of the base material's strength when optimally applied, allowing manufacturers to improve yield rates significantly. Additionally, this technique reduces cycle times by up to 50% compared to traditional bonding methods, amplifying overall production efficiency. Implementing ultrasonic welding can, therefore, be a game-changer for industries reliant on durable plastic components.

Recent advancements in ultrasonic welding technology are transforming the landscape of plastic bonding. As industries increasingly demand more efficient and environmentally friendly manufacturing processes, ultrasonic welding emerges as a leading solution. According to a report from MarketsandMarkets, the ultrasonic welding market is projected to grow from USD 1.25 billion in 2022 to USD 1.83 billion by 2027, reflecting a compound annual growth rate (CAGR) of 7.9%. This growth is driven by the ability of ultrasonic welding to provide quick, clean, and reliable joins without the need for adhesives or additional materials.

Innovations in ultrasonic welding techniques are enhancing precision and versatility in plastic applications. Manufacturers are integrating advanced sensors and automation into welding systems, enabling real-time monitoring and adjustment of process parameters. A study by Research and Markets indicates that automation in welding can improve production efficiency by up to 30% while reducing defects and operational costs. As these technologies continue to evolve, they pave the way for more intricate designs and applications across various sectors, including automotive, electronics, and medical devices, where reliable plastic bonding is critical.

The future of ultrasonic welding looks promising, poised to deliver higher efficiencies and open new possibilities in plastic manufacturing.