Leave Your Message

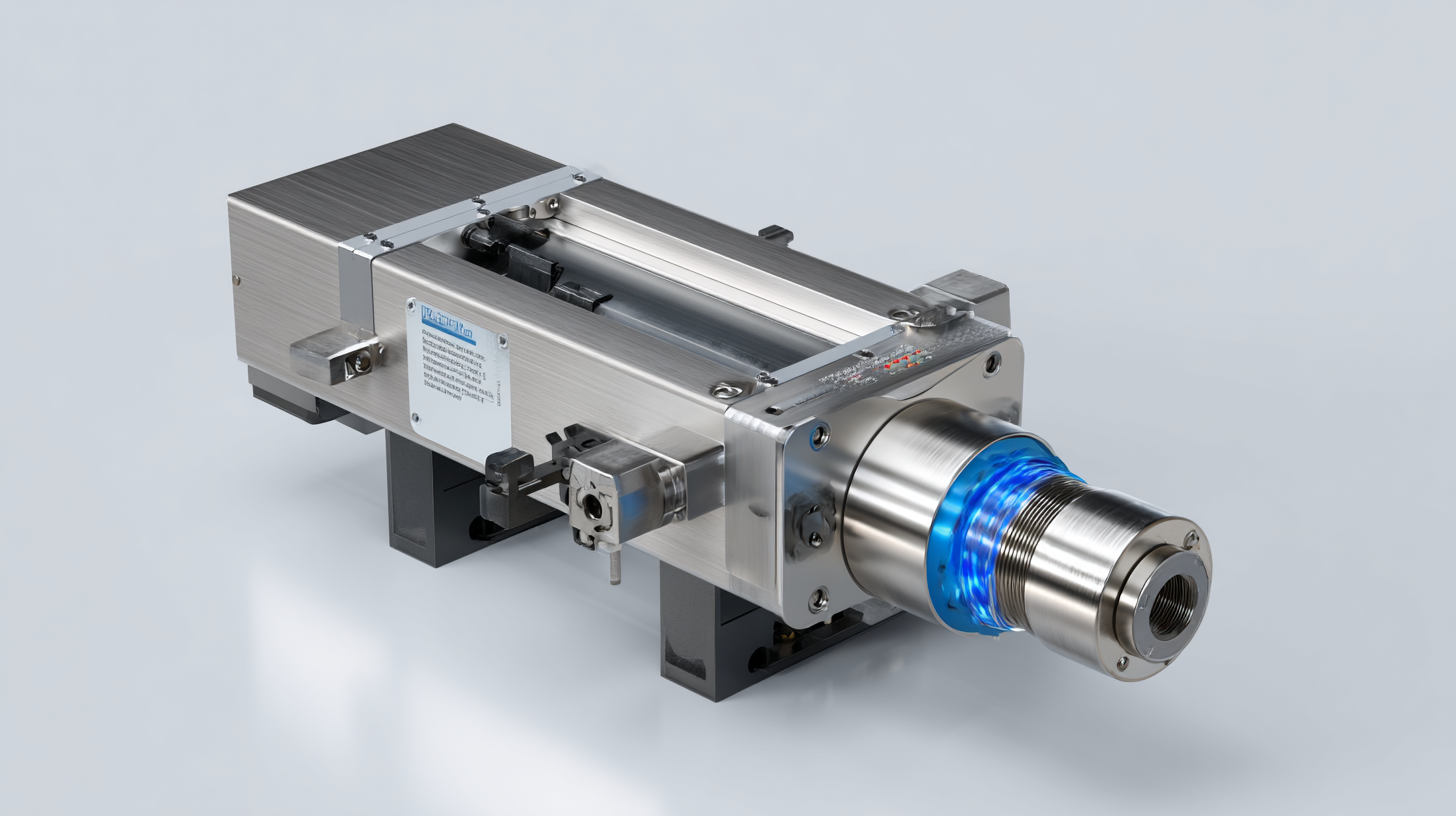

As we step into 2025, the realm of ultrasonic welding continues to evolve, particularly in the domain of wire solutions. The ultrasonic welder for wire has become an indispensable tool across various industries due to its efficiency and precision in creating strong, reliable joints. According to a recent market research report by Technavio, the ultrasonic welding market is projected to grow by over 8% annually, driven by increasing demand in automotive and electronics sectors. This growth can be attributed to the technology's ability to reduce manufacturing costs while enhancing product quality. The versatility of different types of ultrasonic welders tailored for specific wire materials is transforming manufacturing processes, paving the way for innovative solutions. In this blog, we will explore the characteristics and applications of various ultrasonic welding products, providing a comprehensive guide to help industries harness the full potential of this cutting-edge technology.

The rise of ultrasonic welding is poised to transform the manufacturing landscape in 2025. As industries increasingly adopt innovative joining techniques, ultrasonic welding stands out as a key trend due to its efficiency and precision. This method is particularly advantageous in sectors such as automotive and electronics, where lightweight and durable connections are essential. With the global automotive robotics market projected to grow from $11.21 billion in 2025 to $26.76 billion by 2032, the integration of ultrasonic welding technologies will play a pivotal role in meeting production demands while ensuring high-quality outputs.

In China, the market for flux-cored welding wires is also expected to see significant growth from 2025 to 2033, influenced by the continuous advancements in welding applications across various industries, including machinery and shipbuilding. As manufacturers seek to optimize their processes and expand their capabilities, ultrasonic welding is likely to emerge as a preferred method due to its reduced thermal impact and increased speed. The trends indicate a broader embrace of these technologies, underlining the necessity for companies to adapt and invest in ultrasonic solutions to maintain competitive advantages in the evolving landscape.

As industries evolve, the demand for high-quality ultrasonic welding solutions continues to rise. Identifying top manufacturers for your ultrasonic welding needs is crucial for ensuring that you receive reliable and efficient equipment. Start by researching companies known for their innovation and expertise in the ultrasonic welding sector. Online reviews, industry publications, and trade shows can provide valuable insights into which manufacturers are leading the way in technology and customer satisfaction.

Once you have a list of potential manufacturers, consider factors such as their production capabilities, equipment variety, and customization options. Evaluate their history of performance and reputation in the market. A manufacturer that invests in research and development demonstrates a commitment to staying ahead of industry trends, which can directly affect the quality of your welding solutions. Additionally, reaching out to their customer support teams can give you a sense of their responsiveness and willingness to assist with your specific needs. By taking these steps, you can ensure you partner with a manufacturer that aligns with your ultrasonic welding requirements and will help propel your projects into the future.

In 2025, the landscape of ultrasonic welding is set to undergo a remarkable transformation, underscored by the relentless march of digital innovation. Traditional ultrasonic welding techniques have long relied on manual calibration and oversight, often leading to inconsistencies and decreased productivity. However, with advancements in smart technology, we are now witnessing the rise of automated systems that integrate machine learning algorithms. These systems can analyze real-time data, optimize welding parameters, and ensure higher precision in the welding process.

Moreover, the integration of the Internet of Things (IoT) is revolutionizing ultrasonic welding methods. By equipping ultrasonic welding machines with IoT capabilities, manufacturers can monitor equipment performance remotely, predict maintenance needs, and minimize downtime. This connectivity not only enhances operational efficiency but also provides comprehensive insights into production patterns and quality control. As companies shift toward a more data-driven approach, the possibility of achieving flawless welds that meet stringent industry standards becomes a reality, paving the way for more innovative applications across various sectors.

As we look toward the future of ultrasonic welding in 2025, the effectiveness of wire solutions will play a pivotal role in enhancing welding processes across multiple industries. Ultrasonic welding is emerging as a preferred method for fabricating components in sectors like automotive, electronics, and medical devices, owing to its efficiency and precision. According to a report by MarketsandMarkets, the ultrasonic welding market is projected to grow from $1.5 billion in 2020 to over $2.5 billion by 2025, indicating a rising demand for innovative wire solutions that can withstand high-performance requirements.

As the demand for high-quality and reliable manufacturing processes continues to grow, ultrasonic welding has emerged as a vital technology in various industries, particularly in automotive and electronics. In 2025, the emphasis on ensuring quality and reliability in ultrasonic welding equipment will be paramount to meet both regulatory standards and consumer expectations. According to a recent report by MarketsandMarkets, the ultrasonic welding market is projected to reach $1.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 7%. This growth is indicative of the increasing adoption of ultrasonic solutions which require meticulous attention to equipment quality to ensure effective join integrity.

To maintain reliability in ultrasonic welding, manufacturers should prioritize regular equipment maintenance and calibration. Studies have shown that even small variations in frequency can lead to significant defects in welds, impacting product durability. Additionally, following best practices in material selection is crucial; materials like thermoplastics often yield better results when paired with specific ultrasonic frequencies, enhancing the overall weld quality. By investing in high-quality ultrasonic welding equipment and adhering to strict operational protocols, companies can ensure optimal performance, reduce downtime, and ultimately drive efficiency in their production processes.