Leave Your Message

In an era where technological advancements are reshaping industries, the role of the ultrasonic welder has gained paramount importance, transforming manufacturing processes across various sectors. Ultrasonic welding, known for its precision and efficiency, is poised for significant innovations that promise to enhance productivity and reduce operational costs. As we delve into the future of ultrasonic welding, we will explore the emerging technologies and techniques that are not only revolutionizing this field but also addressing the growing demands for sustainable and reliable solutions. From the integration of smart systems and automation to the development of advanced materials suited for ultrasonic applications, this blog aims to illuminate how these innovations are driving industry transformation. Join us on this journey to understand how mastering the use of ultrasonic welders can position businesses at the forefront of manufacturing excellence.

The landscape of ultrasonic welding is rapidly evolving, driven by a wave of emerging technologies that promise to redefine manufacturing processes and product quality. Recent advancements in materials science are enabling the welding of more complex structures with enhanced durability. For example, the integration of smart materials that respond to environmental changes is becoming increasingly common, allowing for more versatile applications in sectors ranging from automotive to electronics.

When considering ultrasonic welding innovations, it’s essential to implement best practices that optimize performance. One tip is to ensure precise control of amplitude and frequency during the welding process, as these factors significantly affect joint strength and quality. Additionally, investing in advanced monitoring systems can provide real-time feedback, allowing for immediate adjustments that enhance efficiency and reduce waste.

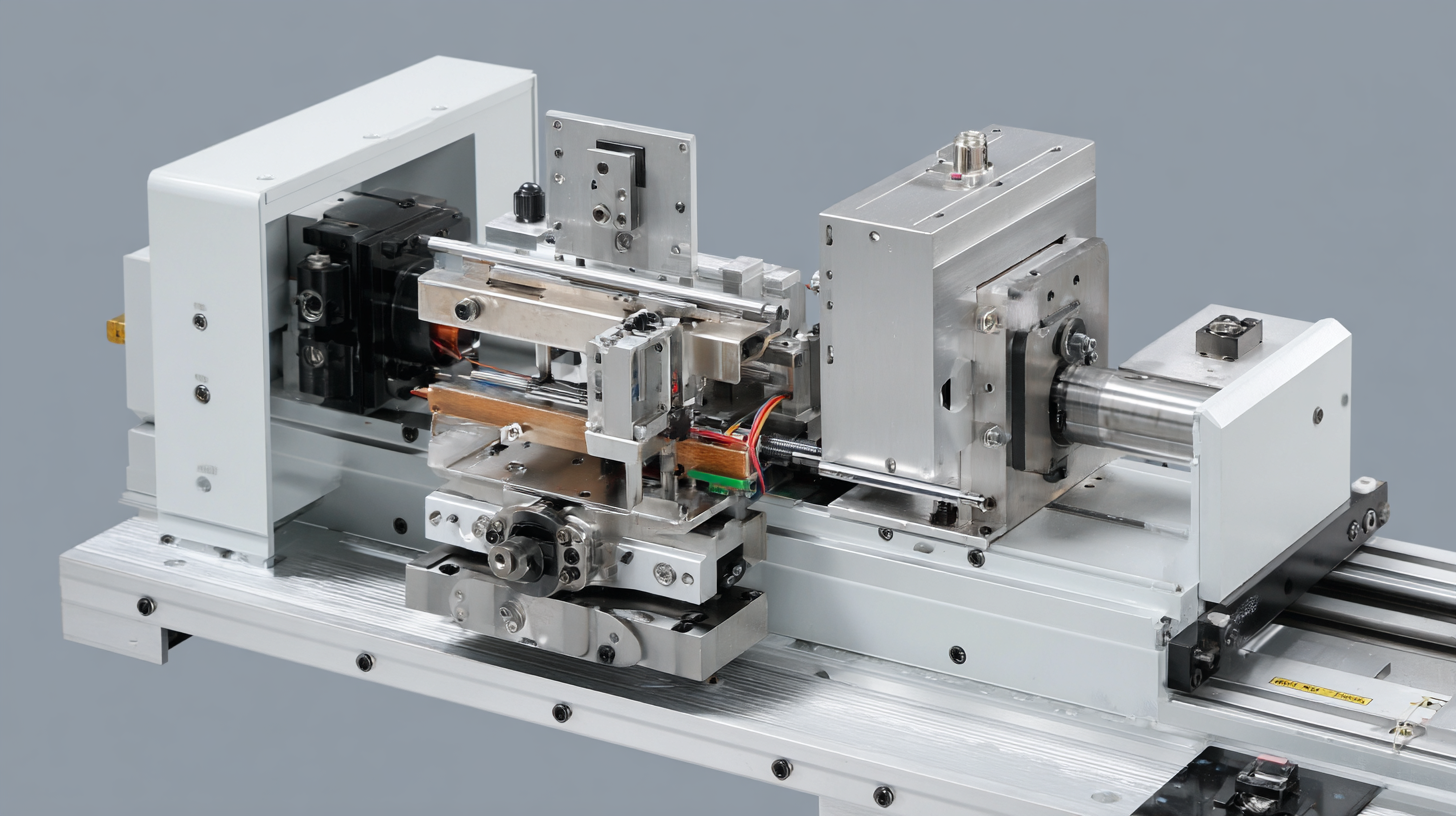

Moreover, automation is playing a crucial role in the future of ultrasonic welding. Automated systems not only increase production speed but also enhance consistency and repeatability in weld quality. Companies should consider integrating automation with data analytics to identify trends and areas for improvement, ensuring they remain competitive in an ever-evolving market.

| Technology Type | Application Areas | Benefits | Challenges |

|---|---|---|---|

| High-Frequency Ultrasonic Welding | Automotive, Medical Devices | Improved speed and efficiency | Equipment cost and training |

| Ultrasonic Spot Welding | Electronics, Packaging | Precise joining with minimal material use | Limited to thin materials |

| Ultrasonic Stitch Welding | Textiles, Nonwovens | Strong seams with flexibility | Complexity in process integration |

| Ultrasonic Consolidation | Aerospace, Composites | Joining dissimilar materials | Requires precise control |

| Robotic Ultrasonic Welding Systems | Manufacturing Automation | Enhanced productivity and repeatability | High initial investment |

The ultrasonic welding industry is undergoing significant transformation, largely driven by key innovations that promise to enhance efficiency and accuracy. With the ultrasonic welding machine market projected to grow at a CAGR of 5.2%, reaching an estimated $1.14 billion by 2034, the demand for advanced technology in sectors like automotive and electronics is surging. Notably, the computer and electrical segments are anticipated to capture 30.1% of this market by 2024, underscoring the critical role ultrasonic welding will play in manufacturing modern electrical components.

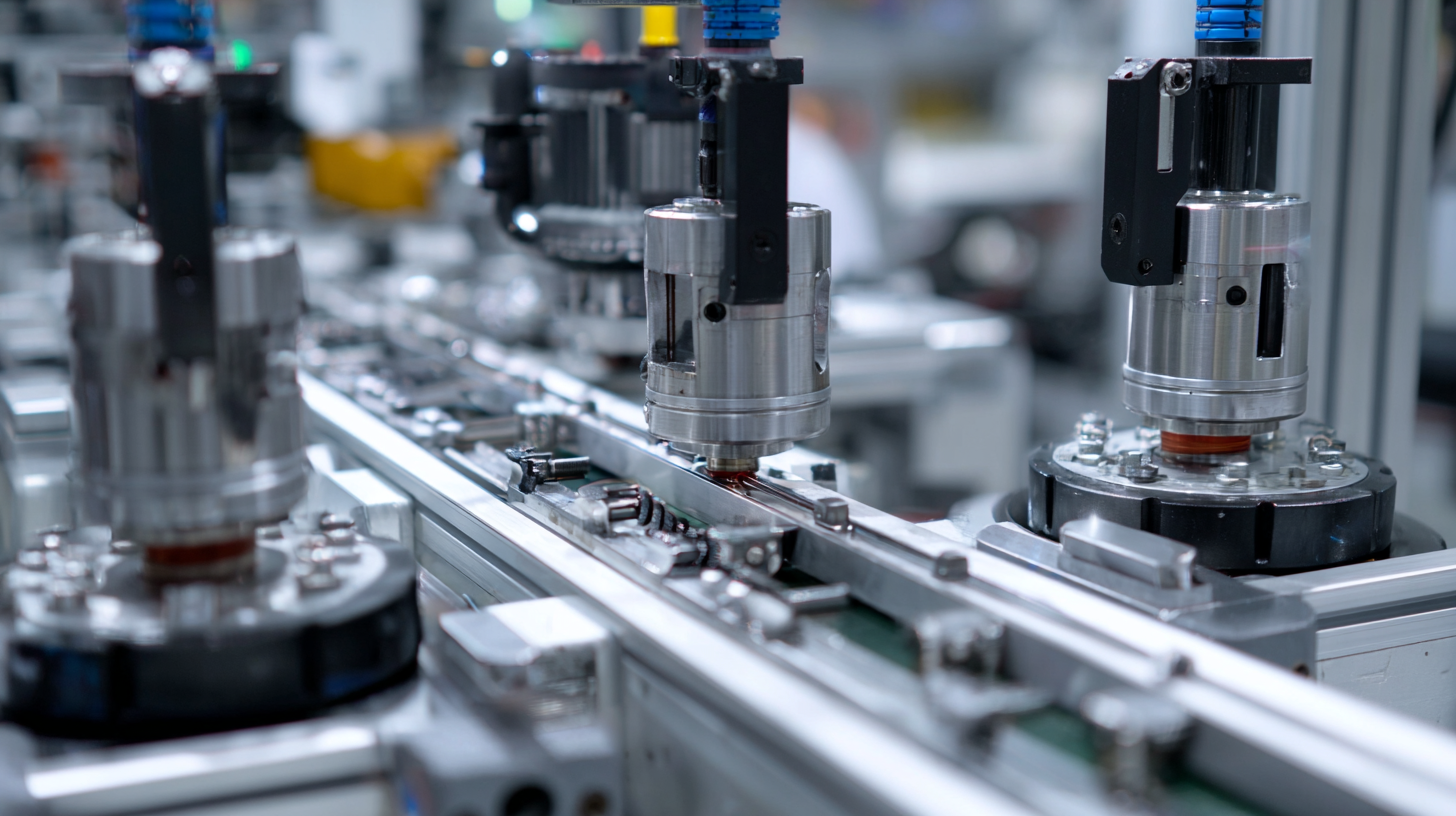

Advancements in ultrasonic welding transducers are also pivotal as the global market outlook brightens for industrial automation. Companies are optimizing these transducers to achieve faster cycle times and improved weld quality, which are essential for the rising demand in precision joining applications, especially in electric vehicle (EV) battery modules. Furthermore, the increasing utilization of ultrasonic technologies in the skin care devices market reflects a broader trend where ultrasonic processes are embraced across diverse industries, creating opportunities for innovation and growth that will shape the future landscape of the ultrasonic welding sector.

Modern ultrasonic welding solutions have transformed manufacturing processes, offering significant advantages that enhance productivity, quality, and precision. By leveraging innovative approaches, manufacturers are now able to achieve superior weld quality through a controlled manipulation of three critical variables: amplitude, duration, and force. These factors are pivotal in ensuring that welds meet stringent quality standards, while simultaneously minimizing waste and reducing cycle times—key considerations in today’s fast-paced manufacturing environment.

Additionally, advancements in ultrasonic technology, such as the integration of servo-driven systems, have further improved functionality and reliability. These systems facilitate greater control over the welding process, allowing for adjustments in real-time to accommodate varying material properties and thicknesses. As a result, manufacturers not only enhance their competitive edge but also open up new possibilities for applications across various sectors, including automotive, electronics, and medical devices. The continuous evolution of ultrasonic welding technology signifies a substantial shift towards more efficient and sustainable production methodologies.

The rapid evolution of ultrasonic welding technologies presents unique challenges for manufacturers looking to implement these innovations. According to a recent report by MarketsandMarkets, the ultrasonic welding market is projected to reach $4.68 billion by 2025, growing at a CAGR of approximately 7.8%. This growth is driven by industries such as automotive and aerospace, where the need for lightweight and efficient joining methods is critical. However, the integration of new ultrasonic welding systems can be hindered by factors such as high initial investment costs and the need for specialized training.

In addition to financial barriers, companies often face challenges related to the adaptation of existing manufacturing processes to accommodate new technologies. A study from Technavio highlights that 34% of manufacturers cite insufficient technical knowledge as a significant obstacle in optimizing ultrasonic welding applications. To tackle these challenges, many firms are investing in employee training programs and collaborating with technology providers to facilitate smoother transitions. By addressing these hurdles, organizations can leverage ultrasonic welding's advantages, including increased speed and reduced thermal damage, to enhance their productivity and competitiveness in the evolving marketplace.

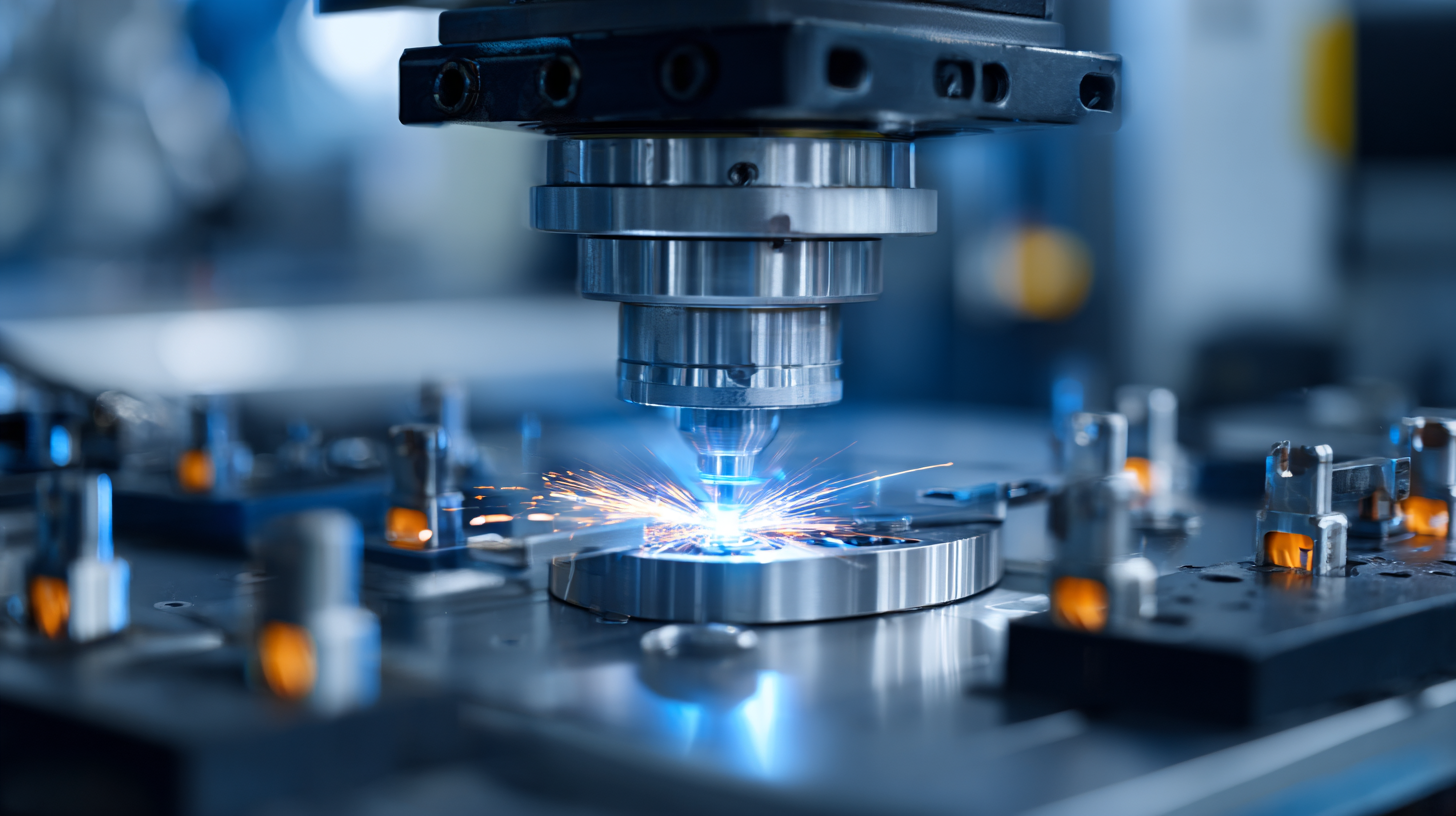

Ultrasonic welding is rapidly transforming various industries, with groundbreaking applications being observed in both aerospace and commercial sectors. Significant advancements in ultrasonic welding technology are now enabling manufacturers to fabricate complex components essential for NASA missions, showcasing remarkable precision and reliability. For instance, this innovative welding technique is being utilized in the assembly of spacecraft components, where typical welding methods may fail due to the lightweight materials involved or the need for minimal thermal distortion.

Case studies underscore the successful applications of ultrasonic welding, particularly in the electric vehicle (EV) market, where it is employed for critical connections such as battery tab and terminal welding. Recent reports indicate a growing demand for reliable energy solutions, with the lithium-ion battery market projected to reach $129 billion by 2027. The integration of ultrasonic welding ensures high-quality joints that enhance battery performance while minimizing material waste. Additionally, ongoing research focused on tool wear monitoring for ultrasonic metal welding demonstrates its viability in mass production, supporting the industry's shift towards more sustainable manufacturing processes.

As universities introduce specialized programs in welding engineering, the education around innovative welding techniques is expanding, promising to further revolutionize manufacturing approaches across multiple sectors. Current studies emphasize the importance of understanding welding process optimization principles, which are crucial for advancing the capabilities of ultrasonic welding in the ever-evolving landscape of industrial applications.