Leave Your Message

As industries continue to evolve amidst rapid technological advancements, the field of welding is undergoing a transformative shift with the integration of innovative techniques such as Welding Ultrasound. This groundbreaking approach leverages the power of ultrasonic technology to enhance quality control and improve safety in welding processes. By exploring the nuances of Welding Ultrasound, we uncover its potential to significantly mitigate risks associated with traditional welding methods. These innovations not only streamline operations but also foster a safer working environment, thereby addressing the critical need for enhanced industry safety measures. As we delve into the future of welding technology, it becomes essential to understand how these advancements can reshape best practices and redefine safety protocols, ultimately leading to a more resilient and efficient industrial landscape.

The integration of ultrasound innovations into modern welding techniques is poised to redefine industry safety protocols and efficiency. Ultrasound technology, initially recognized for its diagnostic capabilities in medicine, has found applications in manufacturing, particularly in welding processes. By utilizing high-frequency sound waves, this technology can detect imperfections in welded joints with unprecedented accuracy, ensuring structural integrity and reducing the risk of failure. Such advancements not only enhance product quality but also significantly lower the chances of workplace accidents, thereby promoting a safer environment for workers.

The integration of ultrasound innovations into modern welding techniques is poised to redefine industry safety protocols and efficiency. Ultrasound technology, initially recognized for its diagnostic capabilities in medicine, has found applications in manufacturing, particularly in welding processes. By utilizing high-frequency sound waves, this technology can detect imperfections in welded joints with unprecedented accuracy, ensuring structural integrity and reducing the risk of failure. Such advancements not only enhance product quality but also significantly lower the chances of workplace accidents, thereby promoting a safer environment for workers.

Moreover, the versatility of ultrasound technology extends beyond just quality assurance in welding. As industries continuously seek ways to optimize processes and reduce costs, ultrasound innovations provide a non-destructive testing method that can be seamlessly integrated into existing workflows. This adaptability not only streamlines operations but also supports a sustainable approach to manufacturing by reducing waste generated from defective products. The adoption of ultrasound in welding is a prime example of how technological advancements can lead to a safer and more efficient industrial landscape.

Ultrasound technology is transforming the welding industry, bringing significant safety enhancements that are increasingly recognized by professionals. Recent studies indicate that the integration of ultrasonic methods can lead to a reduction in defects by up to 30%, particularly in high-stakes environments such as aerospace and automotive manufacturing. This is critical, as even minor welding flaws can lead to catastrophic failures, emphasizing the importance of rigorous quality control measures.

Furthermore, the use of ultrasound in real-time monitoring of weld integrity allows for earlier detection of anomalies, which enhances operational safety. According to a report by the International Welding Institute, industries that have adopted ultrasound technology have reported a 25% decrease in workplace accidents related to welding. The ability to conduct non-destructive testing without interrupting workflow not only boosts productivity but also fosters a safer workspace, allowing operators to focus on their tasks with greater confidence. Such advancements underline the vital role of modern technologies in improving safety standards across welding applications.

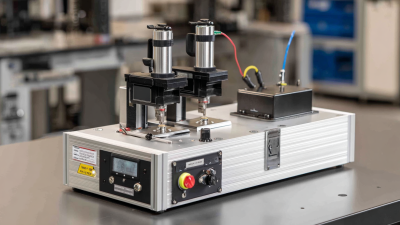

Ultrasonic welding has emerged as a game-changing technology in various industries, offering a cost-effective solution that enhances productivity while ensuring high-quality results. By employing high-frequency ultrasonic vibrations, this method creates a solid-state bond between materials without the need for additional adhesives or mechanical fasteners. This not only reduces material costs but also minimizes the time required for assembly, significantly improving production efficiency. Manufacturers can achieve a rapid return on investment as the streamlined process allows for faster throughput and reduced labor expenses.

Moreover, the safety benefits of ultrasonic welding cannot be overstated. Traditional welding methods often involve hazardous fumes, high temperatures, and complex setups that may pose risks to workers. In contrast, ultrasonic welding operates at lower temperatures and generates minimal emissions, creating a safer working environment. This technology also reduces the risk of fire or accidents related to hot materials, further enhancing workplace safety. As industries continue to prioritize cost-effectiveness and safety, the adoption of ultrasonic welding solutions represents a significant advancement that will shape the future of manufacturing and assembly processes.

| Dimension | Ultrasonic Welding Technology | Traditional Welding Methods |

|---|---|---|

| Safety Level | High | Moderate |

| Cost Effectiveness | High Efficiency | Variable Costs |

| Material Compatibility | Wide Range | Limited |

| Waste Generation | Minimal | High |

| Energy Consumption | Low | High |

| Training Requirement | Moderate | Low |

Ultrasound applications in welding technology are redefining industry standards, particularly when juxtaposed with traditional welding methods. Traditional welding processes, such as MIG and TIG welding, have dominated the industry for decades but come with inherent challenges, including high thermal input, warping, and the risk of defects. According to a report by the International Welding Institute, conventional welding techniques can incur defect rates as high as 20%, significantly impacting safety and reliability in critical applications across sectors like aerospace and automotive.

In contrast, ultrasonic welding offers a safer and more efficient alternative. Utilizing high-frequency vibrations, this technology minimizes thermal distortion and is particularly effective in joining materials like plastics and thin metals. A study published in the Journal of Welding Engineering indicates that ultrasonic welding can achieve defect rates below 5%, thus enhancing overall product integrity. Moreover, with advancements in ultrasound technology, the induced mechanical properties lead to increased strength of the joints, making it an attractive option for industries that require stringent safety standards, such as medical device manufacturing and electronics. By embracing these innovations, organizations can substantially reduce the risks associated with weld failures and improve operational efficiency.

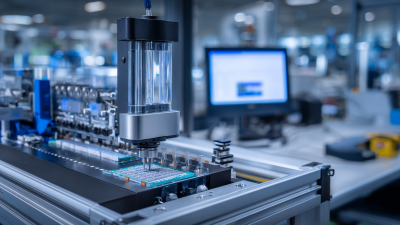

The integration of artificial intelligence (AI) and ultrasound technology is revolutionizing the welding industry, particularly in enhancing safety measures. AI algorithms can analyze data collected from ultrasound inspections, detecting potential faults in welds before they become critical. This predictive capability not only increases the reliability of welded structures but also significantly reduces the risk of accidents, protecting both workers and valuable assets.

Tips: Regular training on new technologies should be a priority for welding professionals. Understanding how AI and ultrasound integration works can empower teams to recognize early signs of weld failure. Additionally, companies should invest in the right tools and software to facilitate real-time monitoring, ensuring that all personnel are equipped to respond swiftly to any identified risks.

Furthermore, the adaptability of AI-driven systems allows for continuous improvement in safety protocols. As these technologies evolve, they can provide tailored solutions based on specific working environments, further enhancing safety standards. Embracing these innovations not only helps comply with industry regulations but also fosters a culture of safety within the workspace.

Tips: Invest in ongoing education and workshops focused on emerging welding technologies. Engaging employees in these learning opportunities promotes a proactive safety culture and gets everyone involved in improving welding practices.