Leave Your Message

In an increasingly competitive global market, the demand for efficient and reliable joining techniques has surged, making the Ultrasonic Hand Welder an essential tool across various industries. According to a recent market research report by Fortune Business Insights, the ultrasonic welding equipment market is projected to reach $1.1 billion by 2026, driven by the increasing need for precision and quality in manufacturing. The Ultrasonic Hand Welder stands out for its ability to bond materials such as plastics and metals without the need for additional adhesives, thus ensuring cleaner, stronger joins and higher production efficiency. As industries strive to enhance their export capabilities, leveraging the expertise in ultrasonic welding can significantly elevate product quality and operational productivity, leading the way in global exports. Embracing this cutting-edge technology not only aligns with sustainability initiatives by reducing waste but also positions businesses at the forefront of innovation in manufacturing practices.

Ultrasonic hand welders have emerged as a critical tool in modern manufacturing, revolutionizing how materials are joined together. Their ability to create strong and durable bonds without the need for adhesives or additional fasteners has streamlined production processes across various industries, from automotive to electronics. These welders utilize high-frequency ultrasonic vibrations to produce heat at the molecular level, enabling quick and efficient welding. This technology not only enhances product quality but also reduces waste and energy consumption, aligning with sustainable manufacturing practices.

The versatility of ultrasonic hand welders makes them indispensable in today’s competitive market. They can be used on a wide range of materials, including plastics, textiles, and even metals, expanding their application in product development. As manufacturers strive for greater efficiency and faster turnaround times, the integration of ultrasonic hand welding technology becomes increasingly valuable. This method not only speeds up production but also ensures consistent and reliable welds, meeting the evolving demands of quality assurance in manufacturing. Consequently, investing in ultrasonic hand welder expertise is essential for companies aiming to lead in global exports and stay ahead in the manufacturing landscape.

In the ever-evolving landscape of global exports, the integration of ultrasonic technology is revolutionizing various industries, particularly in enhancing efficiency and sustainability. One significant advantage of employing ultrasonic methods is the reduction of resource consumption during production processes. Studies have shown that ultrasonic-assisted techniques can lead to a 30% reduction in dye usage in textile applications compared to traditional methods, promoting a cleaner production environment. This aligns seamlessly with the global push towards sustainable practices, appealing not just to environmentally-conscious consumers but also to regulatory bodies aiming for stricter environmental compliance.

Furthermore, ultrasonic technology enhances product quality, which is paramount for exporters looking to gain a competitive edge. The ability to achieve superior bonding in materials through ultrasonic welding translates into stronger, more durable products. In the textile dyeing industry, for instance, ultrasonic assistance enables improved dye uptake, resulting in vibrant colors and a uniform finish, thereby increasing the overall marketability of exported goods. These advantages, coupled with the economic benefits of reduced waste and enhanced product integrity, make ultrasonic technology an invaluable asset for exporters navigating the complexities of the global market.

When investing in an ultrasonic hand welder, understanding the key features is crucial to ensure optimal performance and reliability. A high-quality ultrasonic hand welder should offer adjustable frequency settings, typically ranging from 20 kHz to 40 kHz. This versatility allows manufacturers to tailor the welding process to various materials, enhancing efficiency. According to industry reports, ultrasonic welding technology is projected to reach a market value of $4 billion by 2026, highlighting its growing importance in sectors such as automotive and electronics.

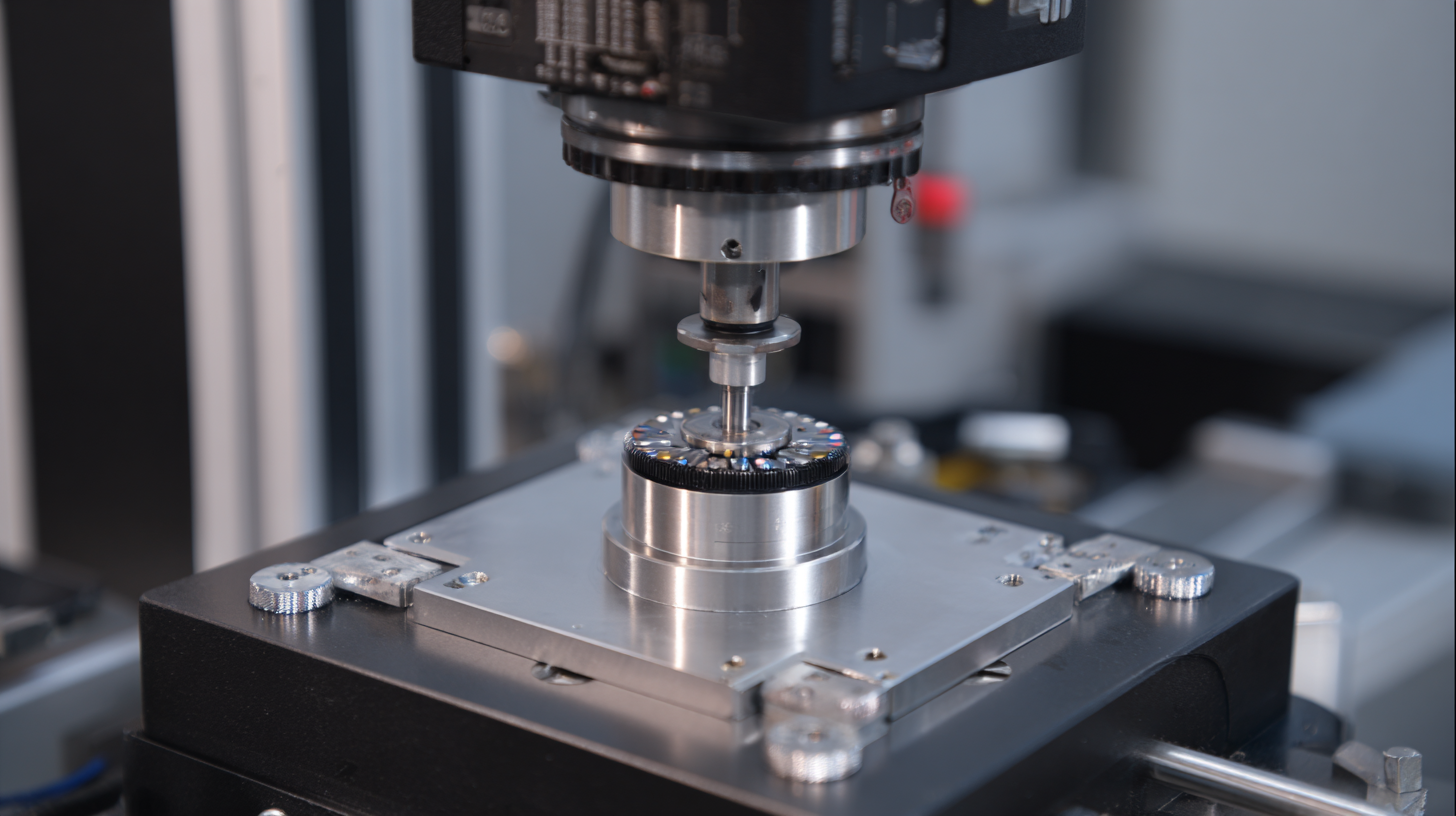

Another critical feature to consider is the transducer's material quality. A robust transducer significantly impacts the welder's durability and the quality of the weld. Look for welders with piezoelectric transducers made from high-grade materials, which ensure consistent performance and long service life. Additionally, some models include advanced cooling systems to prevent overheating during prolonged use, further extending the equipment's life and reliability.

Tips: When choosing an ultrasonic hand welder, always check for user-friendly controls that allow for precise adjustments. This ensures that operators can adapt to different welding requirements quickly and effectively. Also, consider the availability of technical support and service options from the manufacturer, as reliable after-sales support is essential for maintaining high production standards.

Ultrasonic hand welding has emerged as a transformative technology in the manufacturing sector, significantly enhancing product durability and quality across various industries. According to a report by Research and Markets, the ultrasonic welding market is projected to reach $6.3 billion by 2026, driven by increasing demand for high-quality welding techniques that can produce stronger and more reliable joints. This method operates by converting high-frequency electrical energy into mechanical vibrations, which creates heat through friction, allowing materials to bond without the need for additional adhesives or fasteners.

The benefits of ultrasonic hand welding extend beyond mere efficiency; they include improved product lifespan and reduced material waste. A study published in the Journal of Material Processing Technology found that ultrasonic welding can increase joint strength by up to 30% compared to traditional welding methods. This not only implies longer-lasting products but also fewer failures in the field, which can dramatically lower replacement costs and improve customer satisfaction. Manufacturers that leverage ultrasonic welding techniques are better positioned to meet consumer demands for quality and reliability, reinforcing their competitive edge in the global marketplace.

In the rapidly evolving landscape of global exports, ultrasonic welding techniques are at the forefront of innovation. This advanced technology offers manufacturers significant advantages, including faster production times and enhanced joint strength, which are critical in meeting the demands of international markets. Utilizing ultrasonic hand welders not only improves operational efficiency but also minimizes material waste, leading to a more sustainable production process.

Tip: To maximize the effectiveness of ultrasonic welding, ensure that your materials are compatible with this technique. Always conduct preliminary tests to find the ideal parameters, such as frequency and amplitude, for optimal results.

Moreover, the future of ultrasonic welding lies in continuous innovation. As industries increasingly seek automation and precision, integrating sophisticated technologies, such as AI-driven process optimizations, can further enhance the capability of ultrasonic welders. These developments not only improve quality control but also facilitate real-time monitoring and adjustments during the welding process.

Tip: Stay ahead in a competitive market by investing in training for your team. Familiarizing them with the latest ultrasonic welding technologies and techniques can ensure that they harness the full potential of the equipment, leading to improved product quality and efficiency.