Leave Your Message

The 138th Canton Fair in 2025 is poised to showcase a plethora of innovative trends in the realm of manufacturing and assembly technologies, with a significant focus on DIY Ultrasonic Welder solutions. As industries increasingly adopt automation and advanced technologies, the global ultrasonic welding market is projected to reach approximately $7.5 billion by 2026, growing at a CAGR of 6.5% from 2021. The rising demand for high-quality joining processes across sectors such as automotive, electronics, and medical devices drives the need for efficient and customizable solutions, positioning DIY Ultrasonic Welders as a pivotal tool for both small-scale operations and larger manufacturing firms. This event will not only highlight cutting-edge designs and applications but also emphasize the importance of accessible technology in empowering manufacturers and hobbyists alike to integrate ultrasonic welding into their production workflows.

The 138th Canton Fair in 2025 will showcase innovative DIY ultrasonic welding solutions that are particularly beneficial for small to medium enterprises (SMEs). Emerging technologies in this field are set to revolutionize how SMEs approach manufacturing and assembly processes, presenting affordable yet efficient methods to produce high-quality products. With advancements like advanced servo drives and immediate performance feedback, businesses can optimize their production capabilities while maintaining flexibility in their operations.

The 138th Canton Fair in 2025 will showcase innovative DIY ultrasonic welding solutions that are particularly beneficial for small to medium enterprises (SMEs). Emerging technologies in this field are set to revolutionize how SMEs approach manufacturing and assembly processes, presenting affordable yet efficient methods to produce high-quality products. With advancements like advanced servo drives and immediate performance feedback, businesses can optimize their production capabilities while maintaining flexibility in their operations.

Incorporating ultrasonic welding into SME practices not only enhances productivity but also aligns with sustainability goals. The focus on lightweight and greener materials in manufacturing is especially pertinent as industries seek to meet growing environmental standards. Additionally, ultrasonic welding has found widespread applications, including in sectors like aerospace and even space exploration, indicating its versatility and reliability. As these technologies become more accessible, SMEs stand to gain a competitive edge by leveraging innovative welding solutions that cater to their unique needs.

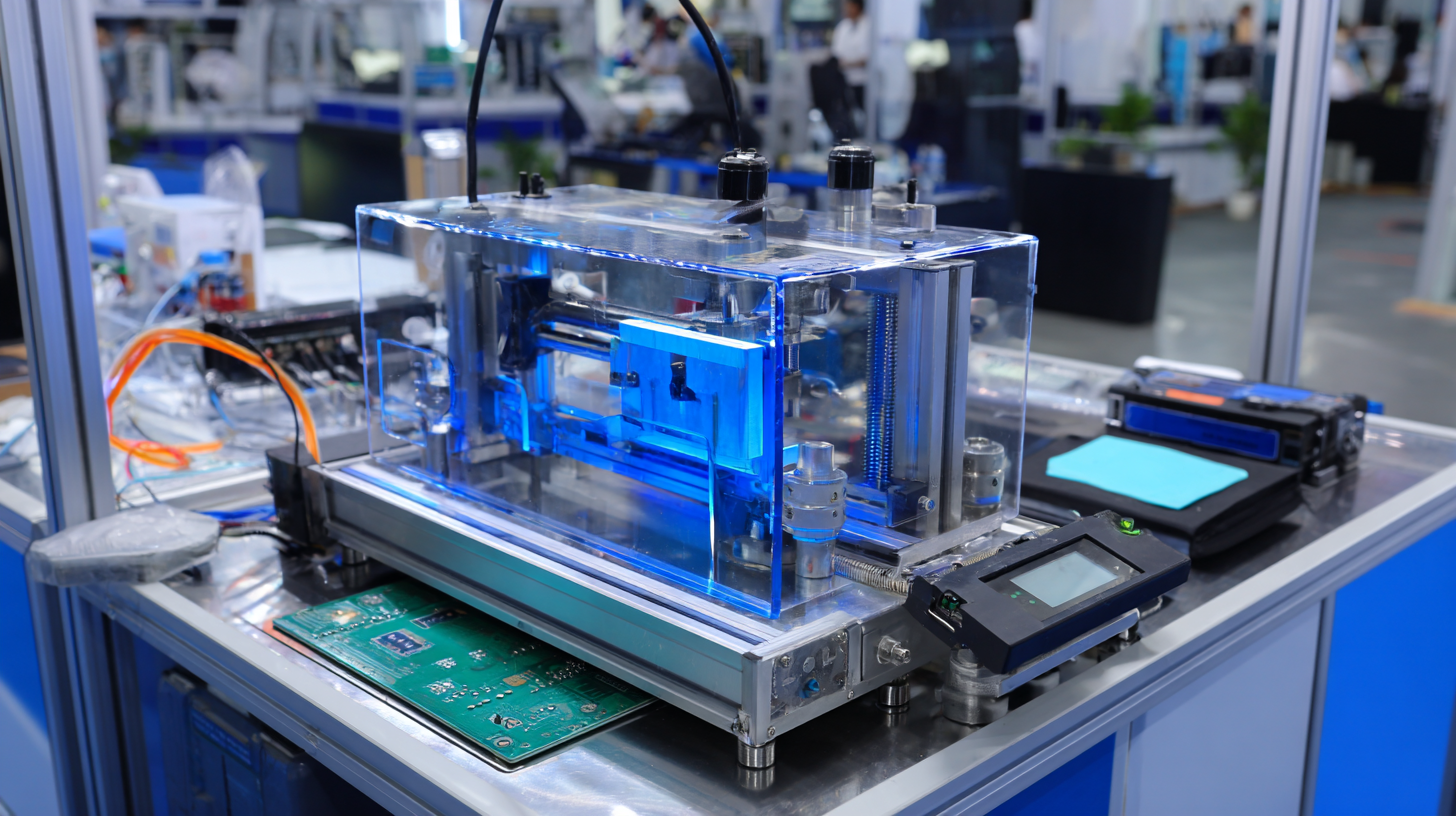

The consumer electronics sector has witnessed a surge in demand for innovative ultrasonic welding solutions, a trend that was evident at the 138th Canton Fair 2025. As manufacturers seek to enhance product durability and assembly efficiency, the use of ultrasonic welding technology has become increasingly prevalent. This technique not only improves the strength of electronic components but also supports tighter tolerances necessary for the miniaturization of devices.

Tips for manufacturers: Consider integrating ultrasonic welding into your production line to meet the growing consumer expectations for seamless design and longevity. Furthermore, invest in training for your workforce to ensure optimal operation of ultrasonic welding equipment. This can lead to reduced defects and improved overall product quality, giving you a competitive edge in the ever-evolving electronics market.

The market demand is fueled by the continuous innovation in consumer electronics, including smartphones, wearables, and smart home devices. These products require advanced assembly techniques to achieve lightweight and compact designs without sacrificing performance or aesthetics. By embracing ultrasonic welding, companies can not only address these demands but also streamline manufacturing processes, ultimately leading to faster time-to-market and increased profitability.

The economic impact of DIY ultrasonic welders in the manufacturing industry cannot be overstated. With the capability to bond various lightweight materials, which are becoming increasingly critical in automobile production, these welders present a cost-effective solution for manufacturers. A recent systematic review highlighted that the integration of lightweight materials can enhance fuel efficiency, contributing positively to the overall economy. For instance, it is estimated that the adoption of advanced manufacturing technologies in the automotive sector could lead to a decrease in production costs by 10-15%, a significant benefit for manufacturers operating on tight margins.

When considering the investment in DIY ultrasonic welders, businesses must perform a comprehensive cost-benefit analysis. Factors such as setup costs, operational efficiency, and long-term savings on material wastage should be taken into account. According to industry reports, assembly plants can achieve energy efficiency improvements of up to 30% through optimized processes, translating directly to reduced operational costs.

Tips: To maximize the benefits of DIY ultrasonic welders, it's essential to regularly monitor equipment performance and maintain a close watch on emerging lightweight material trends. Additionally, investing in staff training can ensure that operators are proficient in using these specialized tools, leading to improved productivity and reduced downtime.

The 138th Canton Fair 2025 showcased a remarkable evolution in welding technologies, particularly highlighting the efficiency advantages of innovative ultrasonic solutions over traditional welding methods. Traditional welding techniques often struggle with speed and precision, resulting in potential drawbacks such as extended production times and diminished material integrity. In contrast, ultrasonic welding incorporates high-frequency vibrations, significantly improving the bonding process. This method not only reduces heat-affected zones but also enhances the strength of the weld joints, leading to improved overall efficiency.

A comparative study sheds light on these advancements, illustrating how ultrasonic solutions can streamline production processes. For instance, the integration of ultrasonic vibration assistance in milling operations has been demonstrated to enhance performance when working with complex materials like carbon fiber reinforced plastic (CFRP). By combining optimized tool structures with ultrasonic technology, manufacturers can achieve sharper and cleaner cuts, minimizing waste and maximizing output. This innovative approach highlights a shift towards smarter manufacturing practices, where precision meets efficiency in an increasingly competitive landscape.

| Aspect | Traditional Welding | Innovative Ultrasonic Solutions |

|---|---|---|

| Welding Speed (items/hour) | 25 | 50 |

| Energy Consumption (kWh) | 1.5 | 0.5 |

| Initial Setup Time (minutes) | 45 | 20 |

| Material Compatibility | Limited | High |

| Joint Strength (MPa) | 15 | 25 |

| Maintenance Frequency (per month) | 3 | 1 |

At the 138th Canton Fair in 2025, the spotlight is set on innovative trends in DIY ultrasonic welder solutions, particularly concerning the increasing focus on sustainability. As industries strive to reduce their environmental footprints, the adoption of eco-friendly materials in ultrasonic welding applications has become a defining trend. Manufacturers are exploring and integrating biodegradable composites and recycled plastics into their products, which not only minimises waste but also caters to a growing consumer demand for green technologies.

The shift towards sustainable materials does not compromise the efficiency and precision that ultrasonic welding is known for. New developments in ultrasonic welding technology allow for effective bonding of these eco-friendly materials without sacrificing performance. Furthermore, this approach enhances competitiveness in the market, appealing to environmentally-conscious consumers. As the industry evolves, the combination of technical innovation and sustainable practices at events like the Canton Fair highlights a future where eco-friendliness is integral to manufacturing processes, paving the way for a more responsible approach to design and production.

The chart above illustrates the major focus areas for innovative DIY ultrasonic welder solutions anticipated at the 138th Canton Fair in 2025. It highlights the emphasis on eco-friendly materials leading the market trends, reflecting the growing need for sustainability in manufacturing processes.