Leave Your Message

In the ever-evolving landscape of manufacturing, maximizing production efficiency is crucial for maintaining competitiveness and profitability. Recent industry reports indicate that the market for Ultrasonic Welding Machines is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 5.4% from 2020 to 2027. This growth is driven by the machine's ability to deliver precision, speed, and energy efficiency, making it an indispensable tool in various sectors, including automotive, electronics, and medical devices. Ultrasonic Welding Machines not only enhance product quality but also reduce operational costs by minimizing waste and maximizing throughput. By leveraging the unique capabilities of these machines, manufacturers can streamline their processes, improve end-product integrity, and ultimately boost their bottom line, illustrating the critical importance of effectively optimizing production efficiency in today's competitive market.

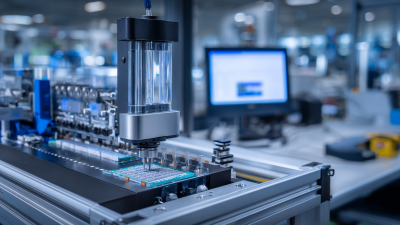

Ultrasonic welding has become an indispensable part of modern manufacturing processes, primarily due to its efficiency and versatility. This technology utilizes high-frequency sound waves to create strong and reliable bonds between various materials, making it ideal for applications in industries such as automotive, electronics, and medical devices. The integration of ultrasonic welding into production lines not only speeds up the manufacturing process but also ensures high-quality results with minimal waste, which is crucial in today’s environmentally conscious market.

Ultrasonic welding has become an indispensable part of modern manufacturing processes, primarily due to its efficiency and versatility. This technology utilizes high-frequency sound waves to create strong and reliable bonds between various materials, making it ideal for applications in industries such as automotive, electronics, and medical devices. The integration of ultrasonic welding into production lines not only speeds up the manufacturing process but also ensures high-quality results with minimal waste, which is crucial in today’s environmentally conscious market.

Tips: To maximize the benefits of ultrasonic welding, ensure that the materials are compatible and properly aligned before the welding process. Additionally, regular maintenance of the welding equipment can prevent downtime and ensure consistent performance.

The ability to weld a wide range of thermoplastics and metals without additional adhesives or mechanical fasteners simplifies the production process. This contributes to reduced assembly times and lower production costs. Moreover, ultrasonic welding is a clean process, generating minimal thermal damage to the materials being joined, which is essential for sensitive components.

Tips: Investing in advanced ultrasonic welding machines with precise control features can enhance the quality of your output and adapt to various product designs. Training operators on best practices will also help leverage the technology effectively.

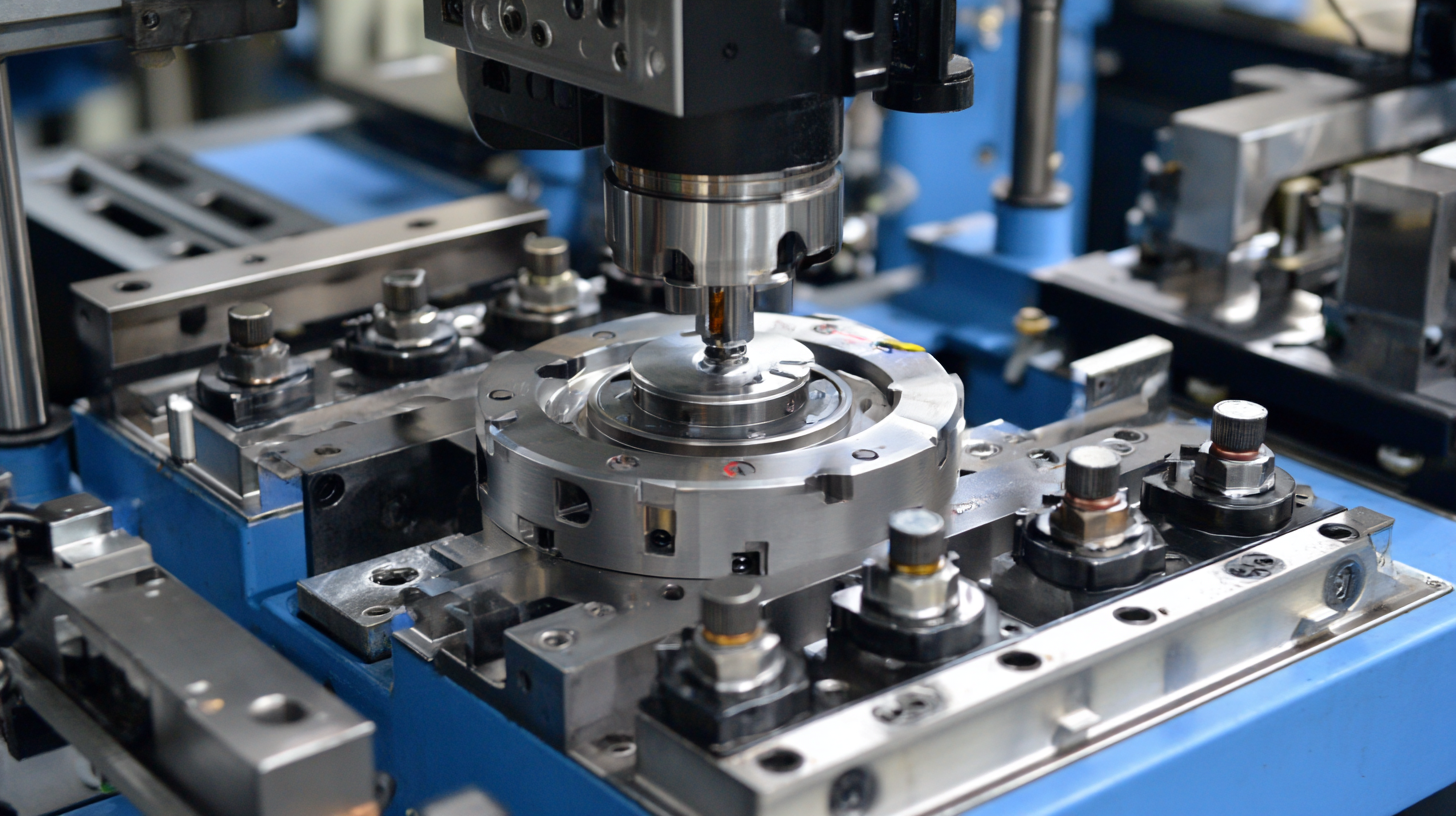

Ultrasonic welding machines have revolutionized production efficiency in various industries by providing fast, reliable, and energy-efficient joining methods. One key feature that enhances efficiency is the ability to deliver consistent and precise ultrasonic vibrations, which minimizes the time required for every weld. This precision ensures a strong bond while reducing material waste, ultimately contributing to lower production costs. Additionally, their quick setup and adjustment capabilities enable manufacturers to shift between different welding tasks with ease, maintaining high throughput.

Another important aspect is the integration of advanced control systems in ultrasonic welding machines. These systems allow for real-time monitoring of the welding process, ensuring optimal parameters are maintained for each job. This not only improves the quality of the welds but also decreases the likelihood of errors and defects. Furthermore, the automation features, such as programmable cycles and integration with robotic systems, greatly enhance production flow. By minimizing manual intervention, manufacturers can achieve higher output rates and reduce labor costs, making ultrasonic welding a preferred choice for optimizing production efficiency.

To optimize production efficiency with ultrasonic welding machines, it's essential to adopt best practices when setting up ultrasonic welding processes. According to a report by Research and Markets, the global ultrasonic welding equipment market is projected to reach USD 1.3 billion by 2025, driven by increasing demand for automation and precision in manufacturing. Proper setup of these systems can significantly enhance throughput and reduce operational costs.

One critical aspect of setting up an ultrasonic welding process is ensuring proper material compatibility. Different materials require specific frequencies and amplitude settings for optimal bonding. For example, thermoplastic materials often perform best at frequencies between 20 kHz and 40 kHz. In addition, maintaining precise control over parameters such as weld time and pressure can lead to improved joint strength and consistency, thus minimizing the risk of defects. According to the International Journal of Advanced Manufacturing Technology, optimizing these parameters can lead to efficiency increases of up to 30%, making a compelling case for meticulously planned setups in ultrasonic welding applications.

| Parameter | Value | Best Practice |

|---|---|---|

| Process Time | 45 seconds | Optimize cycle time for maximum throughput |

| Welding Frequency | 20 kHz | Utilize the correct frequency for material type |

| Force Applied | 50 N | Balance force to prevent material damage |

| Material Type | Polypropylene | Select materials compatible with ultrasonic welding |

| Cooling Time | 30 seconds | Allow sufficient cooling to ensure bond strength |

| Machine Maintenance | Weekly | Regular inspection to avoid downtime |

Troubleshooting common issues in ultrasonic welding operations is essential for maintaining optimal production efficiency. One prevalent issue is improper amplitude settings, which can lead to weak welds or excessive part deformation. According to a report by the International Ultrasonic Technology Association, nearly 30% of welding failures can be attributed to incorrect amplitude adjustments. Ensuring that the amplitude is calibrated to match the material being welded is crucial.

Tip: Regularly calibrate your ultrasonic welding machines and conduct amplitude tests with control samples to identify the optimum settings for different materials. This practice can significantly reduce setup errors and improve weld consistency.

Another common challenge is inadequate surface preparation, which can result in contamination and poor bonding. A study published in the Journal of Manufacturing Processes indicates that approximately 20% of ultrasonic welding defects are caused by unclean or improperly finished surfaces. To combat this, implementing a strict cleaning protocol and using surface inspection techniques can enhance the quality of welds.

Tip: Invest in a quality surface inspection tool and establish a cleaning routine for your components. This proactive approach ensures that all surfaces are ready for effective welding, ultimately improving overall production efficiency.

Ultrasonic welding machines are revolutionizing production efficiency across various industries by leveraging advanced technology to join materials with precision. To effectively measure and analyze production efficiency with ultrasonic technology, companies should focus on key performance indicators such as cycle time, waste reduction, and energy consumption. According to a recent industry report by Grand View Research, ultrasonic welding can reduce cycle times by up to 30%, leading to increased throughput and faster project completion rates.

To maximize these efficiency gains, manufacturers should implement real-time monitoring systems to collect data on the welding process. This data allows for continuous analysis and optimizations. For instance, adjusting the amplitude and welding time based on feedback can significantly enhance weld quality and reduce defects. As reported by the Welding Institute, ultrasonic welding can achieve a defect rate as low as 0.1%, which is markedly lower than traditional welding methods.

**Tip:** Regularly calibrate your ultrasonic welding equipment to maintain optimal performance and ensure consistent weld quality.

**Tip:** Conduct routine training sessions for operators on the latest ultrasonic technology advancements to further enhance efficiency and reduce learning curves in the production process.