Leave Your Message

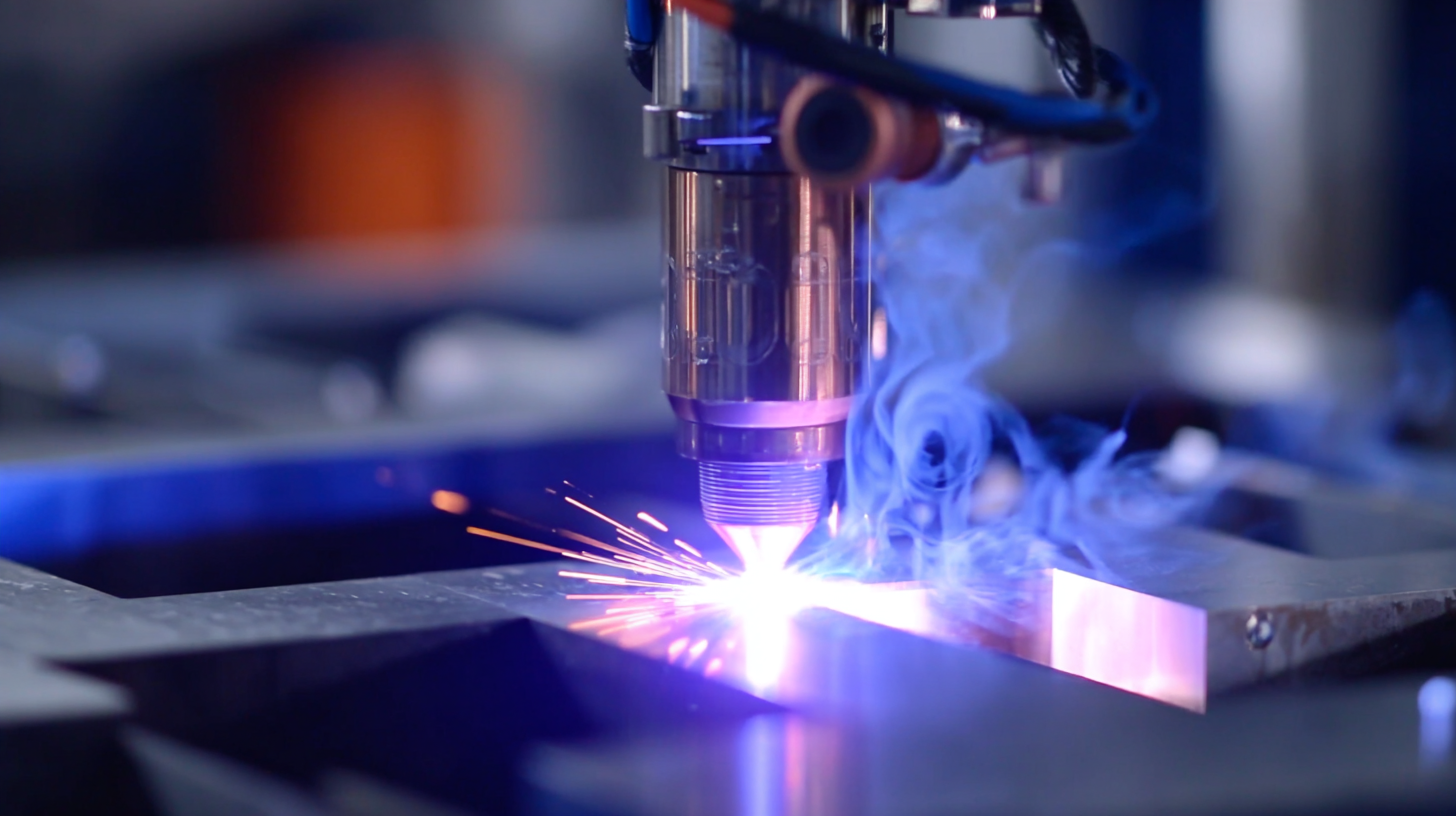

In the quest for enhanced manufacturing efficiency, the integration of

Welding Ultrasound technology has emerged as a groundbreaking solution.

This innovative approach employs high-frequency sound waves to make significant

improvements in the welding process, offering remarkable precision and speed. Manufacturers are increasingly turning to

Welding Ultrasound to not only reduce production times but also to enhance the quality of welds, minimizing

defects and ensuring stronger bonds. As industries face growing

demands for tighter tolerances and reduced operational costs, leveraging this

cutting-edge technology proves critical. In this overview, we will explore essential tips on how to effectively

implement Welding Ultrasound processes in manufacturing settings, highlighting its transformative impact on operational

workflows and overall productivity. Whether you're a seasoned professional or new to the field, understanding and

utilizing Welding Ultrasound can revolutionize your approach to manufacturing challenges.

In the quest for enhanced manufacturing efficiency, the integration of

Welding Ultrasound technology has emerged as a groundbreaking solution.

This innovative approach employs high-frequency sound waves to make significant

improvements in the welding process, offering remarkable precision and speed. Manufacturers are increasingly turning to

Welding Ultrasound to not only reduce production times but also to enhance the quality of welds, minimizing

defects and ensuring stronger bonds. As industries face growing

demands for tighter tolerances and reduced operational costs, leveraging this

cutting-edge technology proves critical. In this overview, we will explore essential tips on how to effectively

implement Welding Ultrasound processes in manufacturing settings, highlighting its transformative impact on operational

workflows and overall productivity. Whether you're a seasoned professional or new to the field, understanding and

utilizing Welding Ultrasound can revolutionize your approach to manufacturing challenges.

Ultrasound technology is rapidly transforming the welding landscape, marking a significant step forward in manufacturing efficiency. As industries strive for optimal performance, the application of ultrasound in welding processes stands out for its ability to enhance precision and control. By utilizing high-frequency sound waves, manufacturers can achieve superior weld quality with less energy consumption, making it a sustainable choice for modern production lines.

Tips: To get started with ultrasound welding, consider investing in equipment with advanced monitoring capabilities. This will allow real-time feedback and adjustments, ensuring optimal weld strength and consistency.

Moreover, the integration of ultrasound technology can streamline operations by reducing cycle times and minimizing scrap rates. This not only leads to cost savings but also enhances the overall productivity of manufacturing facilities. As the industry continues to evolve, embracing ultrasound technology will be crucial for companies looking to remain competitive.

Tips: Regular training for staff on the latest ultrasound techniques will improve their efficiency and adaptability, fostering a culture of innovation within your teams.

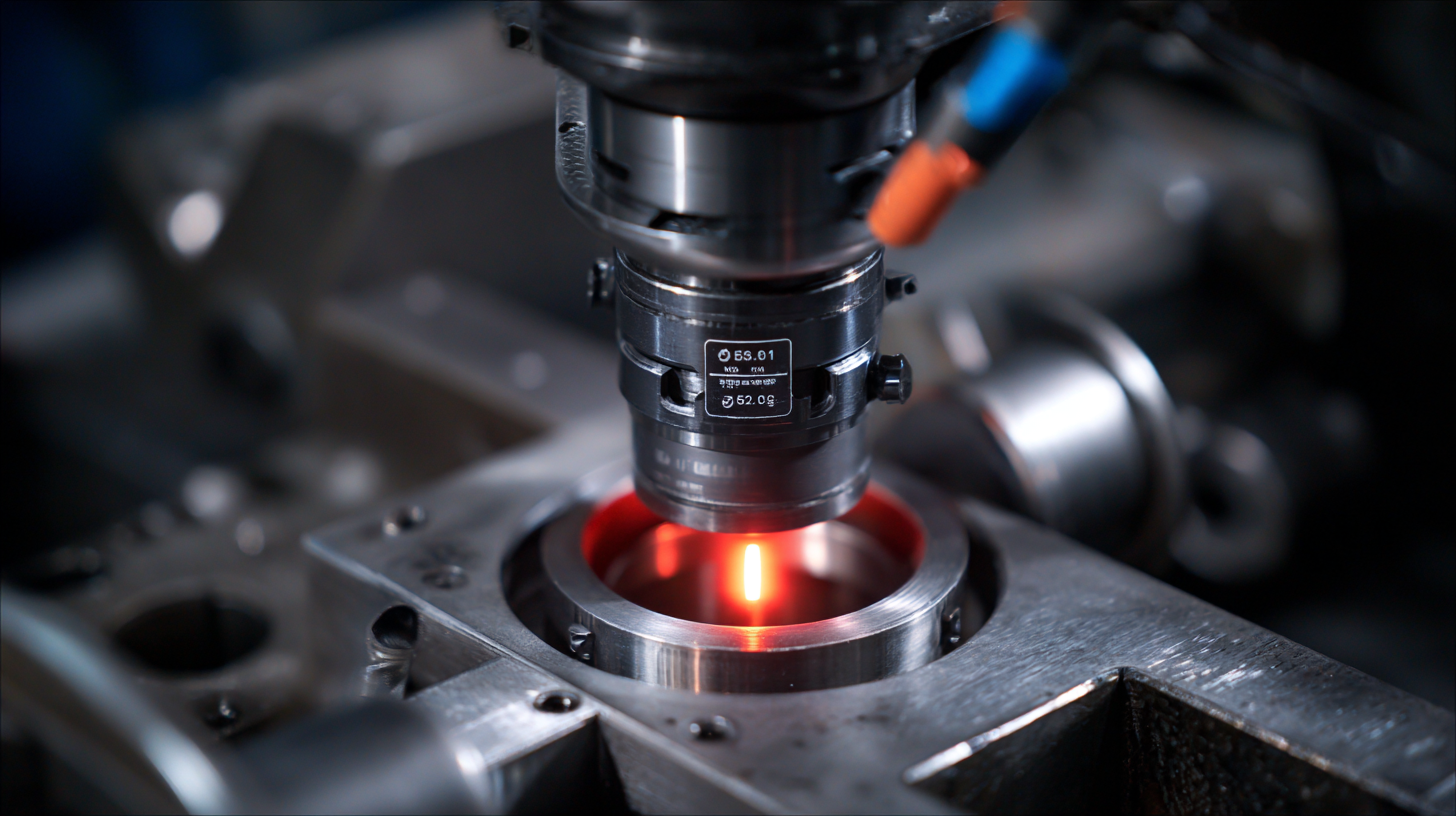

Welding ultrasound technology is transforming the manufacturing landscape by enhancing precision in welding processes, ultimately leading to improved product quality. According to a report by MarketsandMarkets, the global ultrasonic welding market is expected to reach $850 million by 2025, driven by the growing demand for high-quality assembly in industries such as automotive and aerospace. The ability to generate precise ultrasonic vibrations translates into a more controlled and effective welding process, reducing the likelihood of defects that can compromise structural integrity. As a result, manufacturers can deliver products that not only meet stringent quality standards but also exceed customer expectations.

To maximize the benefits of ultrasound technology, manufacturers should consider integrating real-time monitoring systems into their welding processes. These systems can provide valuable insights into the welding conditions, allowing for immediate adjustments to optimize the quality of the welds. Additionally, regular training programs for welding operators on the latest techniques and technologies can significantly enhance the overall efficiency and effectiveness of the welding operation.

Tip: Always conduct regular maintenance on ultrasound equipment to ensure optimal performance and minimize downtime. Additionally, maintaining a clean workspace can help reduce contamination, which is critical for achieving high-quality welds.

| Parameter | Traditional Welding | Ultrasound Welding | Improvement (%) |

|---|---|---|---|

| Weld Porosity | 3.5% | 1.2% | 65.71% |

| Weld Strength (MPa) | 250 | 320 | 28.00% |

| Cycle Time (seconds) | 60 | 45 | 25.00% |

| Material Waste (%) | 10% | 4% | 60.00% |

| Customer Satisfaction (Rating) | 3.8 | 4.6 | 21.05% |

The adoption of welding ultrasound technology is rapidly transforming the landscape of manufacturing efficiency by significantly minimizing production costs. According to a report by the International Institute of Welding, the integration of ultrasonic techniques in manufacturing can lead to cost reductions of up to 30%. This is primarily attributed to its ability to streamline processes, reduce energy consumption, and enhance material integrity while minimizing waste. By utilizing ultrasonic waves, manufacturers can achieve superior weld quality in a shorter duration, thereby enhancing throughput and reducing labor costs.

Moreover, a study published in the Journal of Manufacturing Processes indicates that ultrasonic welding technologies can operate effectively on a variety of materials, including plastics and metals, which broadens their application range and further drives down costs. This versatility allows manufacturers to optimize their operations and reduce the need for multiple machinery setups, thus lowering capital expenditures. As industries seek innovative solutions amidst rising operational costs, the integration of welding ultrasound technology not only positions companies to improve their bottom line but also augments their competitive edge in an evolving market landscape.

In today’s rapidly evolving manufacturing landscape, innovative technologies like welding ultrasound are increasingly essential for maintaining competitiveness. These advanced techniques not only enhance efficiency but also improve product quality and minimize waste. By integrating ultrasound technology into traditional welding processes, manufacturers can achieve precise control over the weld quality, leading to stronger bonds and reduced defects. This technological leap effectively transforms production methods, pushing the boundaries of what is possible in manufacturing.

Tip: To stay competitive, consider investing in training programs that familiarize your workforce with advanced technologies. This knowledge can maximize the benefits of new tools and processes, ensuring they are utilized to their full potential.

Implementing such innovative technologies offers manufacturers a dual advantage: higher operational efficiency and the capacity to produce superior products. Embracing these advancements creates a foundation for sustained growth and a stronger market position. As businesses adopt such forward-thinking approaches, they are not only responding to the demands of modern consumers but also setting the stage for future improvements in manufacturing processes.

Tip: Regularly assess your technology adoption strategies and be open to integrating emerging solutions. This mindset can lead your company to uncover new avenues for efficiency and innovation.

Sustainable practices in welding are becoming increasingly vital as industries transition into Industry 4.0. This new era emphasizes the integration of cutting-edge technology, enhanced automation, and data exchange, all of which hinge on sustainable methodologies. By adopting eco-friendly welding techniques and materials, manufacturers can significantly reduce waste, energy consumption, and harmful emissions. This not only complies with stringent environmental regulations but also enhances the overall efficiency of manufacturing processes.

Furthermore, the incorporation of ultrasonic technology in welding exemplifies a key advancement in sustainable practices. Ultrasonic welding has proven benefits, including reduced heat input and minimal distortion of materials, which results in less energy waste and improved precision in joinery. This technology aligns perfectly with the goals of Industry 4.0—promoting sustainability while increasing productivity. By embracing such innovations, manufacturers can ensure they remain competitive and environmentally responsible, setting a robust precedent for future industrial practices.