Leave Your Message

In the ever-evolving landscape of technology, the demand for

efficient and reliable sensing solutions has propelled

waterproof ultrasonic transducers into the spotlight. According to a recent industry report, the global ultrasonic

sensor market is expected to reach $5.5 billion by 2026, with a significant portion

attributed to the increasing application of waterproof ultrasonic transducers in industries such as

manufacturing, automotive, and

environmental monitoring. These devices offer unparalleled advantages in

harsh and wet environments, ensuring optimal performance despite challenging

conditions. By harnessing advanced ultrasonic technology, these transducers not only enhance measurement accuracy

but also improve safety and operational efficiency.

This step-by-step guide aims to equip industry professionals with the essential knowledge

needed to select and utilize waterproof ultrasonic transducers effectively, thereby maximizing their performance

and application potential.

In the ever-evolving landscape of technology, the demand for

efficient and reliable sensing solutions has propelled

waterproof ultrasonic transducers into the spotlight. According to a recent industry report, the global ultrasonic

sensor market is expected to reach $5.5 billion by 2026, with a significant portion

attributed to the increasing application of waterproof ultrasonic transducers in industries such as

manufacturing, automotive, and

environmental monitoring. These devices offer unparalleled advantages in

harsh and wet environments, ensuring optimal performance despite challenging

conditions. By harnessing advanced ultrasonic technology, these transducers not only enhance measurement accuracy

but also improve safety and operational efficiency.

This step-by-step guide aims to equip industry professionals with the essential knowledge

needed to select and utilize waterproof ultrasonic transducers effectively, thereby maximizing their performance

and application potential.

When it comes to choosing waterproof ultrasonic transducers, understanding the technology behind them is crucial for optimal performance. Ultrasonic transducers are devices that convert electrical energy into ultrasonic waves, allowing for applications such as level measurement, flow measurement, and object detection in various environments. The waterproof aspect is particularly important in industries such as marine engineering, food processing, and wastewater treatment, where exposure to water or harsh conditions can compromise the functionality of standard transducers.

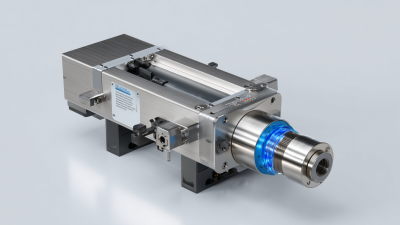

Waterproof ultrasonic transducers are designed with robust materials and sealing techniques that protect against moisture ingress. These transducers typically feature hermetically sealed casings and specialized connectors, which ensure that they can operate reliably even in submerged or high-humidity settings. Additionally, understanding frequency selection is vital; lower frequencies are better suited for long-range applications, while higher frequencies provide improved resolution for detecting closer objects.

By grasping the intricacies of waterproof ultrasonic transducer technology, users can make informed decisions that enhance their operations and ensure longevity in their equipment.

When selecting waterproof ultrasonic transducers, several key factors must be taken into account to ensure optimal performance. Firstly, the material composition is crucial; transducers made from high-grade ceramics or polymers are generally preferred for their durability and resistance to water ingress. According to a report by the International Journal of Acoustics, transducers constructed from these materials can maintain over 90% efficiency even after prolonged exposure to moisture, significantly enhancing their lifespan in aquatic environments.

Another critical consideration is the frequency range of the ultrasonic transducer. Depending on the application, different frequencies are necessary. For instance, lower frequencies (typically around 20 kHz) are often employed in non-destructive testing, while higher frequencies (above 1 MHz) are utilized for precision measurements in fluid analysis. Industry data reveals that selecting the appropriate frequency can lead to a 40% increase in signal clarity and detection capabilities, making it essential for engineers to match the transducer frequency to their specific use case.

This chart compares various performance metrics of selected waterproof ultrasonic transducers based on frequency response, sensitivity, and operational depth.

When choosing waterproof ultrasonic transducers, it is crucial to follow a structured selection process to ensure optimal ultrasonic performance. Start by evaluating the application requirements, such as the operating frequency and environmental conditions. According to a report by the Ultrasonic Industry Association, transducers operating in the 20 kHz to 1 MHz frequency range are typically optimal for most industrial applications, providing a balance between penetration depth and resolution. Understanding these parameters will guide you in selecting a transducer that matches your specific needs.

Tip: Always consider the material compatibility of the transducer with the fluids or solids it will be interfacing with. Certain transducer materials can degrade when exposed to aggressive chemicals, which can severely impact performance.

Furthermore, pay attention to the transducer's packaging and sealing mechanisms. A study by Research and Markets indicated that well-designed waterproofing can enhance the lifespan of a transducer by up to 50%. This aspect is critical for applications in harsh conditions, where moisture ingress could lead to failures. By systematically analyzing these factors, you can ensure that you select an ultrasonic transducer that operates efficiently and withstands the environmental stresses it may encounter.

When it comes to installing waterproof ultrasonic transducers, adhering to best practices is crucial for ensuring optimal performance and reliability. As noted in recent advancements in fetal monitoring technologies, the right choice of tools can significantly impact outcomes. For instance, properly selecting ultrasonic transducers that are not only waterproof but also compatible with the application’s specific conditions can enhance the accuracy of monitoring systems.

One key tip is to ensure that the installation environment is clean and free from contaminants, as dust and moisture can affect transducer functionality. Additionally, it's vital to verify the transducers' frequency and sensitivity specifications against the operating conditions to prevent any signal interference, which can lead to inaccuracies in measurements.

Furthermore, proper calibration of the transducers before usage is essential. Regular maintenance checks and recalibration, as indicated by industry reports, can help in sustaining consistent performance and prolonging the lifespan of the equipment. Investing time in these best practices can lead to improved safety and efficacy in applications such as fetal monitoring, where precision is non-negotiable.

Waterproof ultrasonic technology has become increasingly vital in various industries due to its robust capabilities and versatility. One of the most common applications of waterproof ultrasonic transducers is in marine environments, where they are employed for sonar systems and underwater sensing. These transducers enable accurate measurements of distance and object detection beneath the water surface, contributing significantly to navigation, underwater mapping, and fishing expeditions. Their ability to withstand harsh conditions while maintaining signal integrity makes them indispensable in oceanographic research and underwater construction.

Additionally, waterproof ultrasonic transducers are widely used in industrial applications, such as in oil and gas exploration, where they facilitate non-destructive testing and monitoring of pipelines and equipment. By providing precise data in corrosive environments, these transducers help optimize operational efficiency and safety. Their application extends to medical fields as well, where waterproof ultrasonic devices assist in patient monitoring in aquatic therapy or during procedures requiring sterilization. The integration of waterproof ultrasonic technology thus not only enhances performance across various sectors but also underscores its importance in advancing technology solutions for both commercial and scientific endeavors.