Leave Your Message

The Ultrasonic Welder Machine is transforming manufacturing processes across various industries, boasting efficiency and precision that are game-changers for businesses. According to a recent market analysis by Grand View Research, the ultrasonic welding market is anticipated to reach USD 5.57 billion by 2025, driven by increasing demand for high-quality, durable products. As industries prioritize automation and consistent output, this technology has emerged as an essential tool for streamlining operations while minimizing material waste. In this ultimate guide, we will explore seven surprising benefits of incorporating an Ultrasonic Welder Machine into your business strategy, highlighting how it enhances productivity and reduces costs, ultimately making it a must-have asset in today's competitive market.

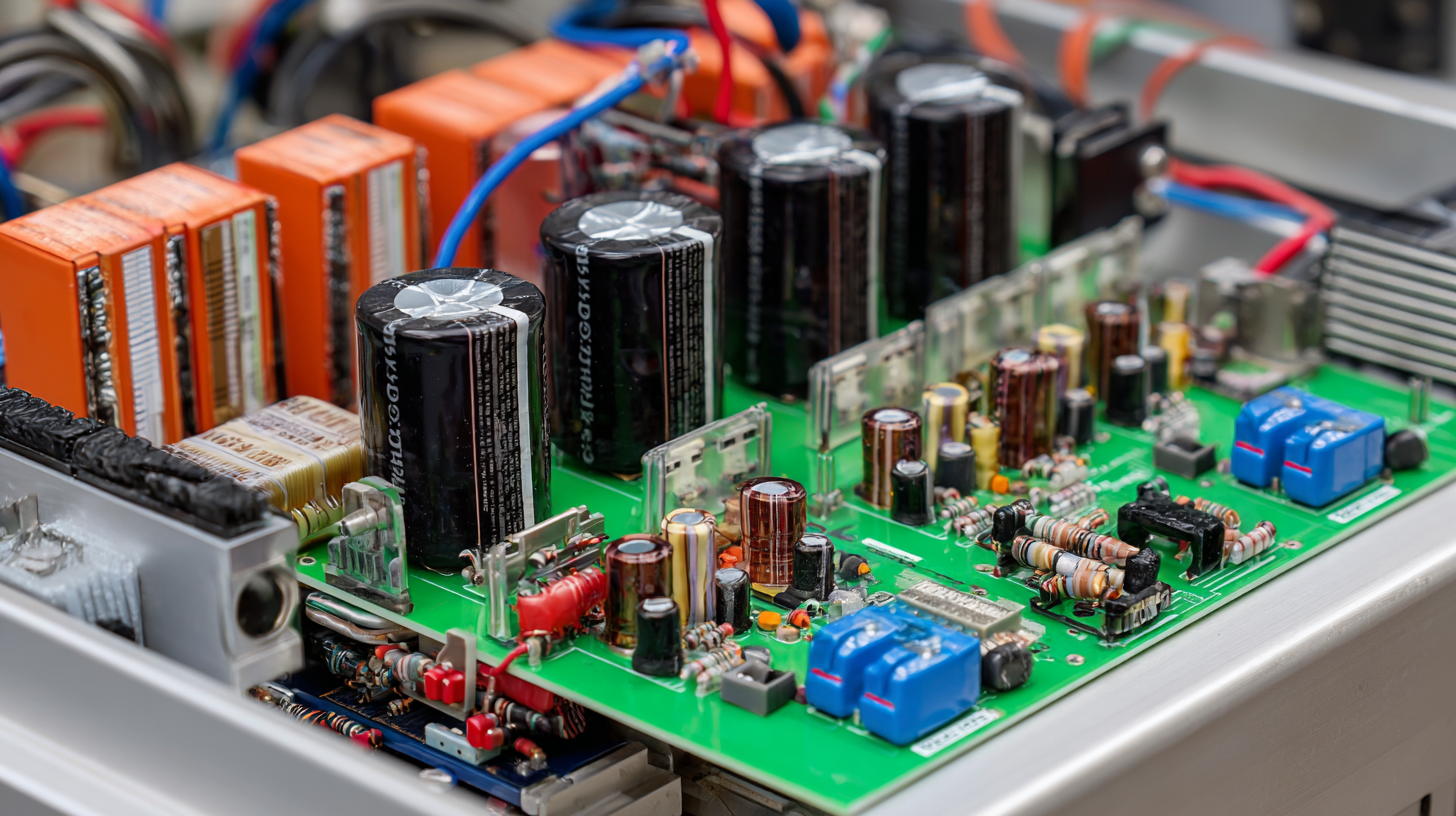

Ultrasonic welding (UW) is revolutionizing the way industries approach durable connections, especially in transportation sectors like electric vehicles and aerospace. Compared to traditional welding methods, UW offers remarkable advantages such as reduced heat input, which minimizes thermal distortion and allows for the joining of dissimilar materials. This capability is crucial in contexts where lightweight and strong connections are essential. The process is significantly faster, enabling higher production rates without compromising the integrity of the weld.

When considering adopting ultrasonic welding in your business, it's beneficial to focus on design strategies that enhance the strength and toughness of the welded joints. Using needle-like structures on aluminum alloys, for instance, can significantly improve performance. Additionally, maintaining consistency in ultrasonic parameters ensures that weld quality remains high.

Tips: To optimize your ultrasonic welding process, regularly calibrate your equipment to prevent wear and ensure uniform energy delivery. Training your staff on the latest techniques will also ensure they can effectively troubleshoot and maximize the system's capabilities for dissimilar metal joints.

When it comes to enhancing your business operations, investing in an ultrasonic welder is a game changer, particularly in terms of cost efficiency. Ultrasonic welders utilize high-frequency vibrations to create energy, which results in quick and reliable bonding processes. Unlike traditional welding methods, they consume less power and reduce material waste, allowing companies to significantly lower operational expenses. This efficiency translates into lower utility bills and improved profit margins over time.

Tip: To maximize the cost benefits of ultrasonic welding, regularly maintain your machines. Routine inspections and timely repairs prolong the lifespan of your equipment, ensuring that you continue to enjoy economic advantages without interruption.

Moreover, ultrasonic welders require less labor compared to conventional welding techniques. This reduction in labor not only saves on salary costs but also allows your team to focus on more critical, value-added tasks. By minimizing the personnel needed for welding operations, businesses can streamline their workforce effectively.

Tip: Train your staff on how to operate ultrasonic welders efficiently. Well-trained employees can quickly adapt to the technology, which boosts productivity and further reduces costs associated with errors or downtime.

In the fast-paced world of manufacturing, enhancing production speed is essential for maintaining a competitive edge, and ultrasonic technology stands out as a powerful solution. Ultrasonic welders, known for their ability to join materials quickly and efficiently, dramatically reduce cycle times compared to traditional welding methods. By creating high-frequency vibrations, these machines facilitate rapid bonding without the need for excessive heat, which minimizes energy consumption and preserves the integrity of temperature-sensitive materials.

Moreover, the incorporation of ultrasonic welding into manufacturing processes can lead to increased consistency and reliability. This is particularly relevant in industries like automotive and electronics, where precision is crucial. The technology not only boosts productivity but also aligns with sustainability goals by reducing waste and energy use. As industries move toward advanced manufacturing practices, integrating ultrasonic technology ensures that companies can keep pace with evolving market demands while promoting eco-friendliness in their operations.

Ultrasonic welding has emerged as a game-changer across various industries, thanks to its remarkable versatility and efficiency. The technology is particularly advantageous in sectors such as automotive, aerospace, and medical, where precise and robust joining solutions are critical. Ultrasonic welders utilize high-frequency vibrations to generate heat, allowing materials to fuse without the need for adhesives or additional bonding agents. This not only streamlines manufacturing processes but also enhances product durability and reduces production costs.

In recent years, there has been a growing trend towards integrating innovative materials in ultrasonic welding applications. For instance, the combination of piezoelectric nanogenerators with conductive nanofibers showcases the potential for enhanced performance in energy-harvesting devices. Additionally, advancements in the understanding of ultrasonic vibrations have facilitated their application in metal processing, paving the way for more efficient manufacturing techniques. As industries continue to seek ways to optimize their production capabilities, ultrasonic welding stands out as a reliable and effective solution, driving innovation and growth in diverse applications.

Ultrasonic welding is gaining traction in various industries due to its precision and strong welds, transforming manufacturing processes. According to a report by Grand View Research, the ultrasonic welding market size is projected to reach USD 4.1 billion by 2025, driven by the increasing demand for high-quality and reliable welding solutions. The technology utilizes high-frequency sound waves to create vibration and heat, resulting in a bond that is often stronger than the base materials themselves. This precision eliminates the need for additional bonding agents, reducing the potential for defects and ensuring that products meet stringent quality standards.

Moreover, the strength of ultrasonic welds makes them ideal for applications in the automotive and electronics sectors, where durability is crucial. Data from the National Institute of Standards and Technology (NIST) highlights that ultrasonic welds can maintain integrity under extreme stress conditions, minimizing the risk of failure in critical components. Businesses leveraging ultrasonic welding can significantly enhance their quality assurance processes, ensuring consistency and reliability in production, which ultimately leads to improved customer satisfaction and reduced rework costs.

| Benefit | Description | Impact on Business |

|---|---|---|

| Increased Production Speed | Ultrasonic welding significantly reduces assembly times compared to traditional methods. | Higher throughput leads to increased revenue potential. |

| Lower Energy Consumption | Uses less energy by applying focused ultrasonic energy for quick welds. | Reduces utility costs, improving overall profitability. |

| High Weld Quality | Provides consistent weld quality and integrity, reducing defects. | Enhanced product reliability and customer satisfaction. |

| Versatility | Suitable for a wide range of materials including plastics and metals. | Allows for diverse product offerings and market adaptation. |

| Automation Capability | Can be easily integrated into automated production lines. | Reduces labor costs and improves manufacturing efficiency. |

| Environmentally Friendly | Minimizes waste and requires no adhesives or solvents. | Supports sustainability initiatives and compliance with regulations. |

| Reduced Labor Intensity | Simplifies the welding process, reducing physical strain on workers. | Improves worker satisfaction and retention while lowering injury rates. |