Leave Your Message

Welding Ultrasound technology is evolving rapidly. Experts in the field highlight its potential to revolutionize the industry. Dr. Emily Johnson, a prominent figure in welding innovation, noted, "Welding Ultrasound reduces defects and enhances precision."

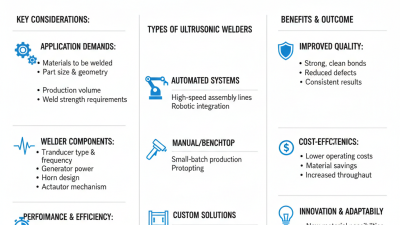

This technology employs high-frequency sound waves to improve weld quality. As the demand for stronger, more reliable welds grows, so does the interest in this method. Many companies are exploring how Welding Ultrasound can ensure better results. However, this innovation does come with challenges.

While the benefits are clear, implementation may not always be straightforward. Training technicians to use this technology effectively is essential. Additionally, understanding the limitations of Welding Ultrasound is crucial. As we look ahead, reflection on these aspects will guide future advancements. The journey of embracing Welding Ultrasound will be critical for the industry's future.

Welding ultrasound technology is evolving rapidly in 2026. This innovation focuses on improving welding quality and efficiency across various industries. Reports indicate that ultrasonic testing can enhance structural integrity. In aerospace, it can reduce welding defects by up to 30%. This accuracy contributes to safety in high-stakes environments.

The introduction of portable ultrasonic devices allows for on-site inspections. These devices are user-friendly, requiring minimal training. They can streamline manufacturing processes. Many operators report a learning curve, but consistent use leads to improved outcomes.

Tips: Always calibrate your equipment before use. Regular training sessions can cut down errors. Encourage feedback from operators to enhance procedures. Reflect on past projects to identify areas for growth. The journey in ultrasonic welding is ongoing, and adaptation is key.

| Innovation Type | Description | Benefits | Applications | Future Prospects |

|---|---|---|---|---|

| Automated Ultrasonic Testing | Integration of AI for real-time monitoring and analysis. | Increased accuracy and efficiency in defect detection. | Pipeline inspection, aerospace components. | Wider adoption in complex fabrication settings. |

| Portable Ultrasonic Welders | Compact devices for onsite welding applications. | Enhanced mobility and convenience. | Field repairs, automotive assembly. | Increased demand for onsite service capabilities. |

| Advanced Welding Sensors | Sensors that provide real-time feedback during welding. | Improved quality control in welds. | Manufacturing processes, construction. | Innovation in quality assurance processes. |

| Integrated Software Solutions | Comprehensive software for design and analysis. | Streamlined workflow and enhanced data management. | Design optimization, simulation. | Growth in digital manufacturing platforms. |

| Hybrid Welding Technologies | Combination of different welding techniques for improved outcomes. | Enhanced material properties and joining strength. | Heavy industry, fabrication shops. | Continued exploration in material joining technologies. |

In recent years, ultrasonic equipment has seen remarkable progress in welding applications. New technologies have enhanced the precision of welds, particularly in challenging materials. These advancements allow for tighter tolerances and higher-quality finished products. Ultrasonic welding can now process materials like plastics and metals more effectively than ever before. This technology enables manufacturers to meet rising production demands.

The latest innovations focus on improving the efficiency of ultrasonic transducers. Enhanced designs provide greater energy output while reducing power consumption. Such developments lead to faster welding cycles. When production speeds increase, quality often suffers. However, these new systems include better monitoring technology to maintain weld integrity. Manufacturers must remain vigilant, as even minor adjustments can impact performance.

User-friendly interfaces on ultrasonic equipment allow operators to configure settings easily. This feature minimizes training time for new employees but could lead to overconfidence. An intuitive design should not replace the need for thorough understanding. As technology evolves, the balance between automation and human skill remains essential. Continuous education in welding technology is crucial for both efficiency and safety.

This chart illustrates the key advances in ultrasonic equipment for welding applications, showcasing the technological improvements across various parameters in 2026.

The impact of ultra-high frequency waves on welding efficiency is profound. These frequencies enhance the energy transfer during welding processes. Traditional welding methods struggle with heat dispersion. However, ultrasound technology offers a solution. The precise application of high-frequency waves concentrates energy. This focused energy reduces the time needed to achieve the desired weld strength.

Moreover, the use of ultra-high frequency waves leads to finer control over the welding process. It minimizes defects in the welds, which can often result from overheating or improper fusion. However, the technology is not without challenges. Manufacturers must grapple with integrating this advanced technique into existing systems. Training personnel to utilize this technology effectively can also be an obstacle. Ensuring quality while adopting innovations requires a thoughtful approach.

Another area worth reflecting on is the energy consumption involved. While ultra-high frequencies are efficient, they may present higher initial costs. Balancing these costs with the potential for increased productivity is crucial. As the industry continues to evolve, these innovations could redefine welding practices. Nonetheless, it’s essential to continuously assess their practicality in real-world applications.

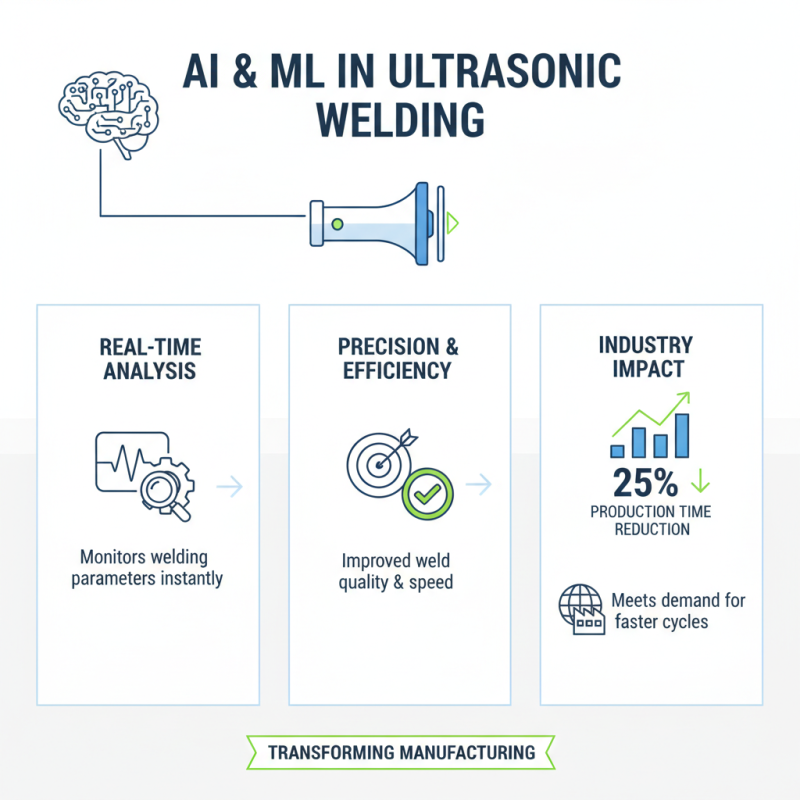

The integration of AI and machine learning in ultrasound welding is transforming the industry. By analyzing welding parameters in real-time, these technologies ensure better precision and efficiency. Recent industry reports show that implementing AI can reduce production time by up to 25%. This enhancement is vital for meeting growing demands for faster production cycles.

Machine learning algorithms process vast amounts of data collected during welding operations. This allows for predictive maintenance, reducing downtime significantly. Surprisingly, about 30% of welding defects occur due to human error. AI systems can help minimize these mistakes. They suggest adjustments to the welding process based on historical data, helping operators make better decisions.

Despite these advancements, challenges remain. The technology requires skilled personnel to interpret AI recommendations effectively. There's also a risk of over-reliance on automated systems, which could lead to complacency. As we move forward, balancing human oversight with AI efficiency is crucial. This combination could shape the future of welding technology in ways we are just beginning to understand.

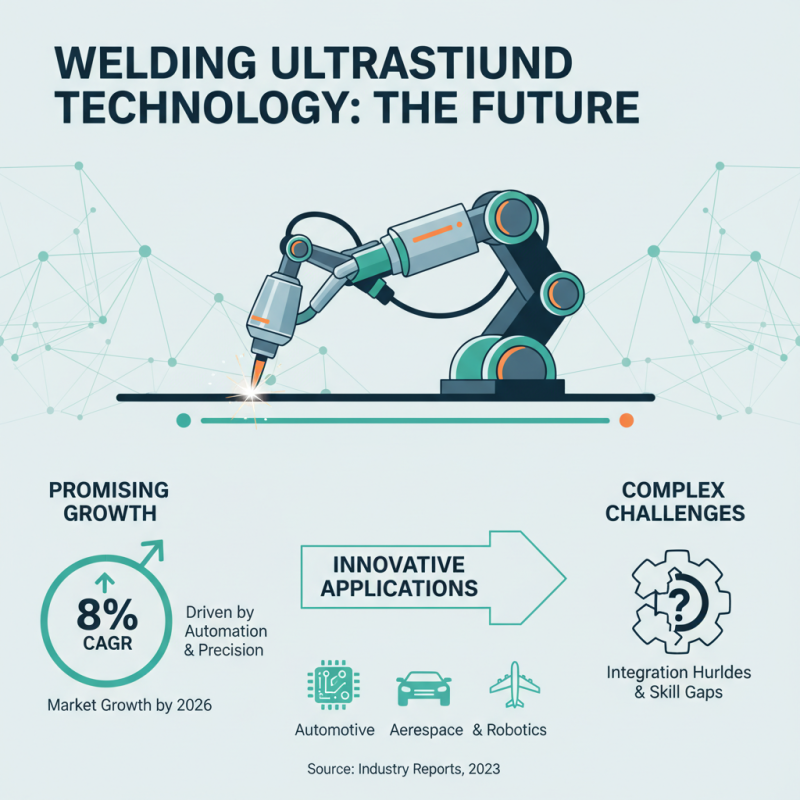

The future of welding ultrasound technology is both promising and complex. Recent industry reports indicate that the market is expected to grow at a CAGR of over 8% by 2026. This growth is driven by increased automation and the need for precise welding techniques. Innovative applications are emerging, yet challenges remain.

Advancements in sensor technology are crucial. Modern sensors enhance accuracy but also bring higher costs. Integrating these sensors with existing systems proves tricky. The industry must address interoperability to maximize efficiency. Moreover, training personnel on new technologies can slow adoption rates.

Another trend is the focus on sustainability. As companies seek to reduce waste, ultrasound technology can help ensure precise material usage. However, there is a lack of standardized practices in the application of ultrasound in welding. Addressing these gaps is important for widespread acceptance. As we move forward, balancing innovation with practicality will be key to the success of welding ultrasound technology.