Leave Your Message

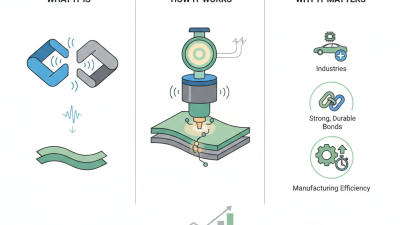

As we approach 2026, understanding what to look for in a top ultrasonic welder factory is crucial for industry stakeholders. John Smith, a renowned expert in ultrasonic technology, states, "Choosing the right factory can make or break your production efficiency." This highlights the significance of making informed choices.

An effective ultrasonic welder factory should prioritize quality and innovation. Look for advanced technology and skilled workforce. These elements are vital for ensuring consistent and reliable welding. However, not all factories meet these criteria. Many may claim excellence but lack the essential certifications or experience.

It's worth reflecting on past choices. Some companies have faced issues due to poor factory selection. Analyzing previous partnerships can help avoid similar mistakes in the future. Thus, visiting potential ultrasonic welder factories and assessing their operations is a wise move. Ultimately, the right factory can enhance production processes and lead to long-term success.

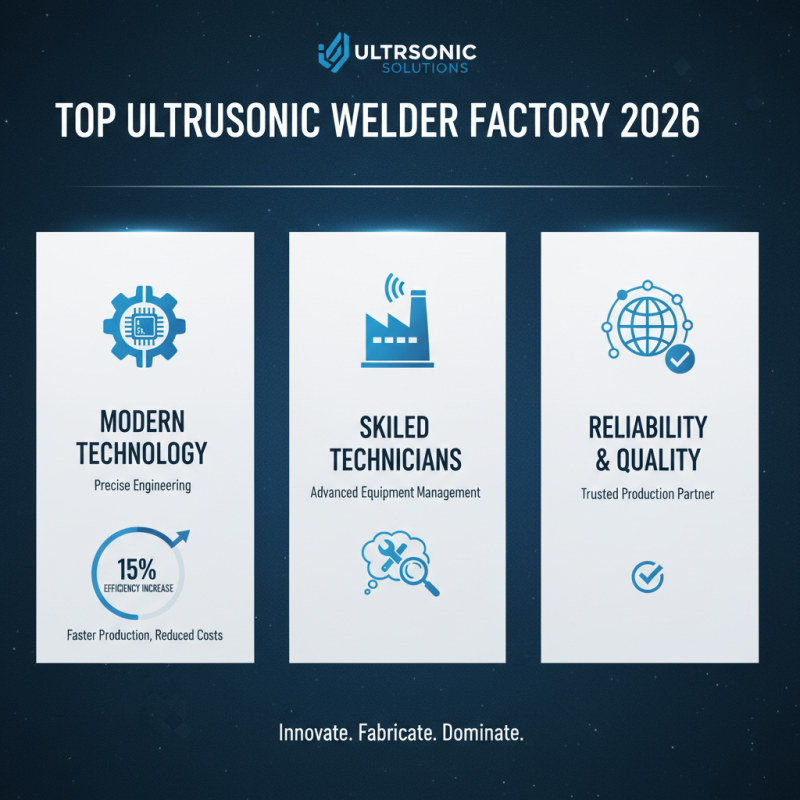

When choosing a top ultrasonic welder factory in 2026, several key features should stand out. A reliable factory must possess modern technology and precise engineering capabilities. Reports indicate that ultrasonic welding technology has seen a 15% increase in efficiency over the past five years. This efficiency translates to faster production times and reduced costs. It is essential that the factory employs skilled technicians who can manage advanced equipment.

Moreover, quality control is critical. Look for factories that implement rigorous testing protocols. According to industry standards, 90% of defects can be caught with proper quality assurance checks. Factors like material compatibility and weld strength should be thoroughly evaluated. Many factories overlook these aspects, leading to increased waste and customer dissatisfaction.

Another important feature is the factory’s flexibility. The ability to adapt to changing demands can set a factory apart. With market trends shifting rapidly, factories that can pivot effectively tend to outperform their competitors. Yet, some may struggle to achieve this level of agility. Always investigate how a factory plans to stay competitive in the evolving market landscape.

When evaluating a top ultrasonic welder factory in 2026, certifications and industry standards play a pivotal role. These elements ensure that manufacturers adhere to quality and safety protocols. ISO 9001 certification is a must-have. This standard guarantees consistent quality in manufacturing processes. Factories with ISO certifications often see 20% fewer defects. This can significantly impact your production line efficiency.

Additionally, look for compliance with ASTM and IEC standards. These guidelines define performance and safety benchmarks. A factory's adherence to these can assure you of its dedication to quality. According to industry reports, 70% of manufacturers consider these standards vital when choosing suppliers.

Tips: Check for recent audits. A factory should provide clear documentation of compliance. Regular updates reflect commitment. Invest time in assessing their quality management processes. A factory without updated certifications may raise red flags about its operations.

Staying informed on relevant certifications is essential. The landscape of manufacturing changes rapidly. Not every factory keeps up with new regulations. Confirming their adherence to current standards can save complications later. A factory should be a partner, not just a supplier.

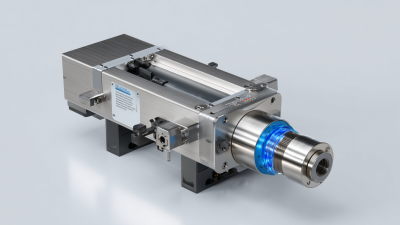

Ultrasonic welding machines have evolved significantly. In 2026, technological advancements will play a key role in their efficiency. New models will feature enhanced precision. They will reduce energy consumption. This makes them more sustainable. Also, automated processes are becoming common. They increase productivity and minimize human error.

When choosing a factory, consider the types of machines they produce. Look for factories that offer customization options. This allows for tailored solutions that fit specific needs. Pay attention to the materials they use for production. High-quality materials often result in better durability.

Tip: Always check client reviews. This can give insight into a factory's reliability.

Furthermore, factories that invest in R&D often lead the market. Innovation in ultrasonic welding technology is crucial. Yet, not all advancements are flawless. Some new features may require adjustments. Relying too heavily on technology can cause oversights.

Tip: Regular training for staff is essential. An informed team can better handle new technologies.

When assessing an ultrasonic welder factory in 2026, production capacity takes center stage. A factory’s ability to scale up operations directly affects its competitiveness. Look for facilities that can adapt quickly to demand changes. Flexibility in production lines can lead to greater efficiency and lower costs.

Efficiency is also critical in evaluating a factory. Analyze the workflows and processes in place. Are they streamlined? Inefficiencies could lead to delays and increased costs. Pay attention to how quickly orders are fulfilled. Timely delivery impacts customer satisfaction.

Moreover, consider the technology used in production. Modern ultrasonic welders incorporate advanced automation. This can increase both output and precision. However, over-reliance on technology may come with risks. What happens if systems fail? A factory should balance technology use with skilled labor. Human oversight can help mitigate potential issues that arise from automation.

When searching for a top ultrasonic welder factory in 2026,

customer service is paramount.

Efficient communication can make a significant difference. A responsive team is crucial,

especially when urgent issues arise. Fast email replies and phone support can enhance the overall experience.

You want to feel valued and heard.

Technical support is equally important. Factories should offer training on their machines.

This ensures users understand equipment operation and maintenance. Comprehensive manuals and online resources also help.

However, not all factories provide enough information. This can lead to difficulties during usage.

Adequate support fosters a better understanding of the technology.

Look for factories that prioritize these aspects. Transparency

about their support structures is vital. Engaging with their customer service can reveal their commitment.

Observing how they respond to inquiries can be telling.

Ultimately, effective customer service and technical support lead to improved operations

and satisfaction in the long run.