Leave Your Message

As the global market increasingly emphasizes efficiency and precision in manufacturing, the demand for advanced technologies in welding processes is surging. Specifically, the "Ultrasonic Welder For Wire" is gaining traction in various industries due to its ability to provide high-quality joins with minimal thermal distortion. According to a recent market analysis report by ResearchAndMarkets, the ultrasonic welding equipment market is projected to grow at a CAGR of 6.5% from 2021 to 2026, reaching a valuation of over $1.5 billion by the end of the forecast period. This growth trajectory highlights the critical role of ultrasonic welding in sectors such as automotive, electronics, and medical devices.

The upcoming 2025 China Import and Export Fair, known as the 138th Canton Fair, serves as an ideal platform for industry players to explore new opportunities and innovations in ultrasonic welding technology, particularly in wire applications, paving the way for enhanced manufacturing capabilities in this fast-evolving market.

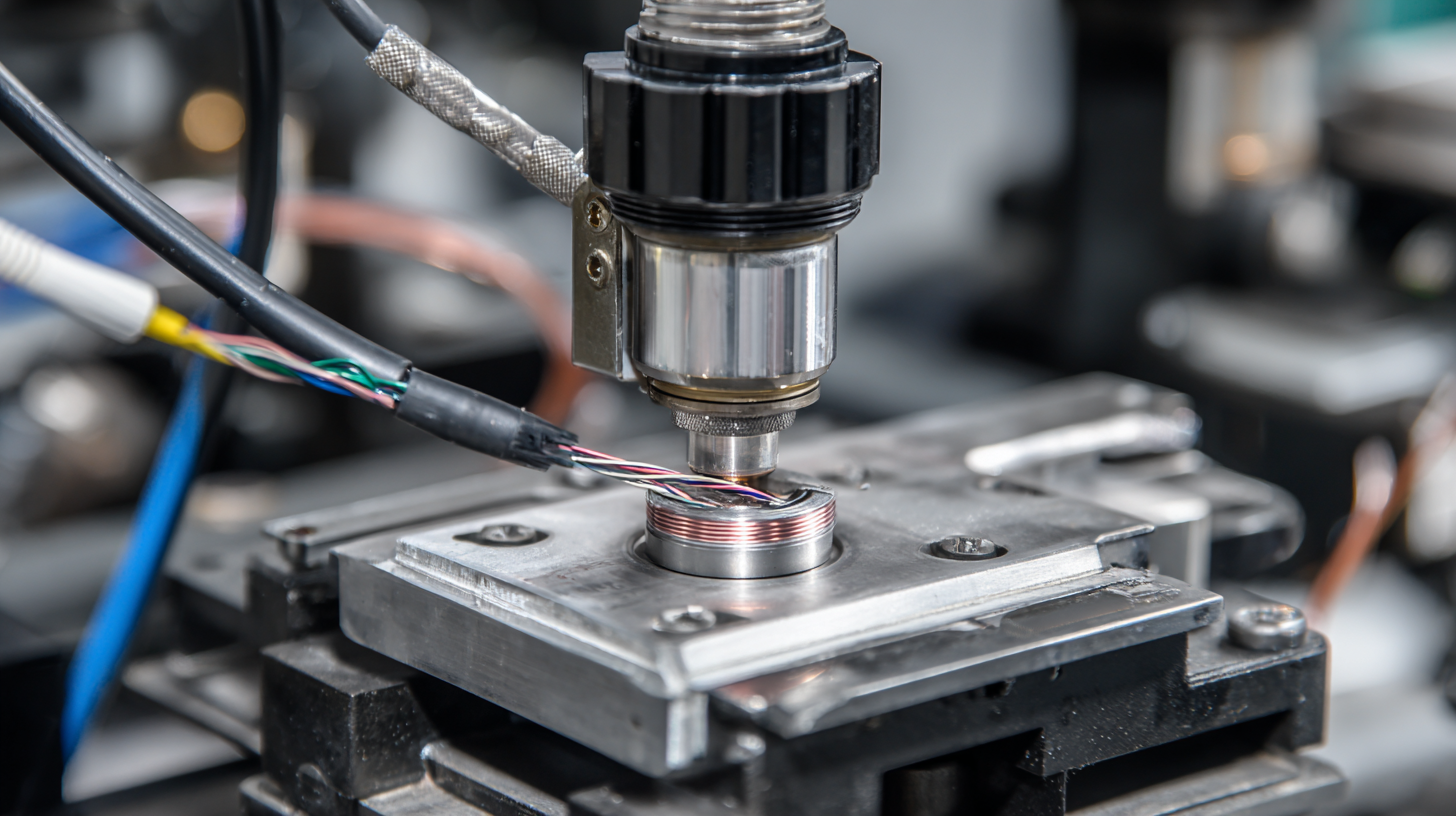

Ultrasonic welding has emerged as a transformative technology in the field of wire manufacturing, providing innovative solutions that enhance productivity and product quality. By utilizing high-frequency ultrasonic vibrations, manufacturers can achieve strong, precise welds without the need for additional materials or significant heat, which can compromise the integrity of the wire. This method is particularly advantageous for joining dissimilar metals and delicate wire components, making it ideal for industries like electronics, automotive, and telecommunications.

At the 2025 China Import and Export Fair, the opportunities for integrating ultrasonic welding in wire fabrication will be prominent. Exhibitors will showcase advancements in machinery and techniques that demonstrate the efficiency and reliability of ultrasonic technology. From faster processing times to reduced energy consumption, the benefits are clear. As manufacturers seek to optimize their processes and improve product performance, the adoption of ultrasonic welding technology could meet the growing demand for high-quality wire products in an increasingly competitive market.

The ultrasonic welding industry is poised for significant growth, particularly as we approach the 2025 China Import and Export Fair. With advancements in technology driving efficiency and innovation, ultrasonic welders are becoming essential tools across various sectors, including automotive, electronics, and medical devices. Companies are increasingly recognizing the advantages of ultrasonic welding, such as its ability to bond dissimilar materials and generate strong joints without the need for adhesives or additional fasteners.

Market insights indicate that the demand for ultrasonic welders is set to rise, with an increasing number of manufacturers seeking to incorporate this technology into their production lines. The trend towards automation and the push for more sustainable manufacturing processes are further fueling the interest in ultrasonic welding. As industries strive to improve productivity and reduce waste, ultrasonic welding presents a compelling solution that aligns with global sustainability goals, ultimately enhancing the competitiveness of businesses in the international market.

The demand for ultrasonic welding solutions is witnessing significant growth due to various key factors. Industries are increasingly adopting these technologies for their efficiency, precision, and ability to join dissimilar materials without the need for additional fasteners or adhesives. The push for automation in manufacturing processes has also contributed to the rising popularity of ultrasonic welding, as companies seek to enhance their production rates and reduce labor costs.

Tips for those considering ultrasonic welding include evaluating the compatibility of materials, as this technology excels at joining certain combinations that traditional methods struggle with. It's vital to conduct preliminary tests to determine the optimal parameters for successful welding. Additionally, investing in quality equipment can greatly affect the reliability and longevity of the welding process, ensuring consistent outcomes.

Other driving factors include the growing emphasis on sustainability, as ultrasonic welding reduces material waste compared to conventional methods. Coupled with advancements in sensor technology and digital integration, manufacturers can achieve higher levels of quality control, making ultrasonic welding an increasingly attractive option.

The advancement of ultrasonic welding technology presents both challenges and solutions, particularly in the context of the 2025 China Import and Export Fair. One of the primary challenges in ultrasonic welding for wires lies in ensuring optimal joint strength while maintaining the integrity of the materials involved. Variations in wire diameters, materials, and surface conditions can complicate the welding process. Manufacturers must address these inconsistencies to achieve reliable and reproducible welds.

To overcome these challenges, the industry is focusing on innovative solutions, such as the use of advanced monitoring systems that provide real-time data during the welding process. These systems can detect anomalies and adjust parameters on-the-fly, ensuring that weld quality remains consistent despite fluctuations in input variables. Additionally, research into new techniques and materials is paving the way for more effective ultrasonic welding applications, making the technology more accessible and versatile for a broader range of uses at the upcoming fair and beyond.

The 2025 China Import and Export Fair will serve as a pivotal platform for networking, especially for industries focused on ultrasonic welding technologies. As the market for ultrasonic welders continues to expand—with a projected growth rate of 8.5% annually, reaching an estimated value of $2.3 billion by 2026—manufacturers and suppliers will gather to explore collaborative opportunities. This fair will attract key decision-makers and innovators, allowing participants to establish valuable connections that can lead to synergistic partnerships and advancements in ultrasonic welding applications for wire processing.

Attendees can expect to interact with industry experts who will share insights on the latest advancements in ultrasonic welding technology. With an increasing demand for efficient, high-quality joining processes in various sectors such as automotive, electronics, and medical devices, the fair will highlight how ultrasonic welding can enhance productivity and reduce production costs. Reports indicate that companies utilizing ultrasonic welding methods have seen a reduction in material waste by up to 30%, further demonstrating the technology's attractiveness. As the industry evolves, the networking opportunities at this event will be instrumental in fostering innovation and driving growth in the ultrasonic welding sector.