Leave Your Message

The field of manufacturing is experiencing significant advancements, particularly through the integration of Welding Ultrasound technologies. According to a recent market report from ResearchAndMarkets, the ultrasonic welding market is expected to grow at a CAGR of 5.3% from 2021 to 2026, reflecting an increasing adoption across various industries due to its efficiency and precision.

Welding Ultrasound offers innovative methods to join materials, especially in sectors like automotive and electronics, where lightweight and durable components are essential. This technology utilizes high-frequency sound waves to create strong molecular bonds without the need for additional materials, which not only enhances product quality but also minimizes environmental impact.

As industries strive for better performance and sustainability, understanding the innovations behind Welding Ultrasound is crucial for manufacturers looking to maintain a competitive edge in a rapidly evolving market.

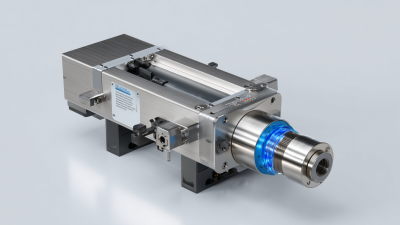

Welding ultrasound technology represents a significant advancement in the field of materials joining, leveraging high-frequency sound waves to enhance the welding process. By generating ultrasonic vibrations, this innovative method promotes better penetration and fusion of materials, particularly in difficult-to-weld materials like plastics and metals. The key principle involves using ultrasonic transducers, which convert electrical energy into mechanical vibrations, resulting in a more efficient welding process that minimizes thermal impact on the surrounding materials.

The applications of welding ultrasound technology are diverse and expanding rapidly. In the automotive industry, this technique is employed for assembling lightweight components, contributing to fuel efficiency while maintaining structural integrity. Moreover, in the medical field, it plays a crucial role in bonding delicate instruments and prosthetics, ensuring precision and reliability. As industries increasingly seek sustainable and efficient manufacturing methods, welding ultrasound technology stands out as a promising solution, enhancing productivity while reducing waste and energy consumption.

This bar chart illustrates the different applications and their respective adoption rates of welding ultrasound technology across various industries in 2023. The data reflects a growing trend in utilizing this innovative technology to enhance welding processes and ensure quality control.

Recent advancements in ultrasonic welding technology have significantly transformed the way industries approach the joining of materials. One of the key innovations has been the integration of digital controls, which enables precise management of energy input and process parameters. This ensures consistent weld quality and enhances the reliability of the Ultrasonic welding process. With real-time monitoring capabilities, manufacturers can quickly identify and rectify issues, leading to increased efficiency and reduced downtime in production lines.

Another notable development is the refinement of ultrasonic transducer designs. New materials and engineering techniques have improved the performance and durability of these transducers, allowing for higher power output and better resonant frequencies. This has expanded the range of materials that can be successfully welded, including challenging thermoplastics and composite materials. As a result, companies are not only achieving stronger welds but also benefiting from improved energy efficiency, which is crucial for sustainable manufacturing practices. These innovations are paving the way for broader applications of ultrasonic welding across diverse industries, from automotive to electronics.

Ultrasonic welding technology is emerging as a revolutionary alternative to traditional welding techniques, particularly in industries where precision and efficiency are paramount. Unlike conventional welding methods that rely on high heat and filler materials, ultrasonic welding uses high-frequency sound waves to create solid-state joints between materials. A comparative analysis reveals that ultrasonic welding can reduce cycle times by up to 80% while providing a higher consistency in bond strength, with studies indicating joint strengths exceeding 90% of the base material. This makes it particularly advantageous for industries such as automotive and electronics where minimizing stress on components is crucial.

Tips for successful ultrasonic welding include ensuring proper alignment of the materials to be joined, as misalignment can greatly affect bond quality. Additionally, selecting the right amplitude and pressure settings can significantly enhance the effectiveness of the weld. Regularly maintaining and calibrating ultrasonic equipment is essential to maintain optimal performance and minimize downtime, as industry reports suggest that improper maintenance can lead to a 25% increase in operational costs.

In contrast, traditional welding techniques often demand significantly more energy and longer cooling times, which can result in thermal distortion and weakened joints. Implementing ultrasonic welding processes not only boosts operational efficiency but also improves overall product durability in applications ranging from medical devices to consumer electronics, thereby aligning manufacturing practices with the growing focus on sustainability and waste reduction in the industry.

| Criteria | Ultrasonic Welding | Traditional Welding |

|---|---|---|

| Energy Source | Ultrasonic vibrations | Heat from an electric arc or flame |

| Temperature | Lower temperature (below melting point) | High temperature (above melting point) |

| Materials Used | Plastics, metals, and composites | Metals, ceramics, and more |

| Speed of Joining | Very fast (seconds) | Relatively slower (minutes to hours) |

| Heat Affected Zone (HAZ) | Minimal HAZ | Larger HAZ |

| Cost Efficiency | Higher initial setup cost but lower operational costs | Lower initial setup cost but higher operational costs |

| Skill Level Required | Moderate skill | Varies from basic to advanced skill |

The growing adoption of ultrasound technology in manufacturing is reflected in various sectors, particularly in the portable ultrasound market, which is on a robust upward trajectory. Valued at $2.16 billion in 2024, the market is projected to reach $3.84 billion by 2030, representing a compound annual growth rate (CAGR) of 9.0%. This surge indicates a significant shift towards the integration of advanced ultrasound systems in operational processes, enhancing productivity and efficiency across different manufacturing environments.

In a related domain, the urology ultrasound devices market is also witnessing impressive growth. Expected to be valued at USD 1.21 billion in 2024, it is forecasted to grow at a CAGR of 6.17% from 2025 to 2030. This trend underscores the critical role of ultrasound technology in medical and healthcare applications, ensuring high-quality diagnostic capabilities. As industries recognize the immense benefits of ultrasound technology—from precision in manufacturing to improved patient outcomes in healthcare—the demand for innovative solutions is set to expand significantly.

As the welding industry continues to evolve, innovations in ultrasound technology

are paving the way for enhanced precision and efficiency. The integration of this technology in welding processes allows for

real-time monitoring and analysis, ensuring higher quality results and minimizing defects.

As we look to the future, several exciting trends are emerging that are likely to shape the next phase of welding ultrasound innovations.

As the welding industry continues to evolve, innovations in ultrasound technology

are paving the way for enhanced precision and efficiency. The integration of this technology in welding processes allows for

real-time monitoring and analysis, ensuring higher quality results and minimizing defects.

As we look to the future, several exciting trends are emerging that are likely to shape the next phase of welding ultrasound innovations.

One significant trend is the increasing application of artificial intelligence

and machine learning. By leveraging vast amounts of data collected during the welding process, these systems can predict potential failures

before they occur, leading to proactive measures that enhance operational efficiency. Additionally, advancements in sensor technology are enabling even greater detail

and accuracy in data collection, transforming how weld quality is assessed. With these developments, the welding sector can look forward

to a new era defined by smart, adaptable processes that not only increase productivity but also ensure safety and reliability in critical applications.

Moreover, as industries demand more sustainable practices, welding ultrasound technology is expected to contribute to

greener methodologies. By optimizing energy consumption and reducing

material waste through precise measurements and adjustments, companies can align themselves with environmental goals while still

achieving high-performance results. The growing emphasis on sustainability will likely drive further research and development in ultrasound

technologies, fostering innovations that cater to both quality and ecological responsibility.