Leave Your Message

The ultrasonic cable welding industry is rapidly evolving. Market research shows a projected growth rate of 8.5% annually from 2023 to 2026. This trend creates a pressing need for effective methods in using an Ultrasonic Cable Welder. Industry expert, Dr. Emily Harper, emphasizes, "Efficiency is the key to maximizing the benefits of ultrasonic technology."

Despite its advantages, many still face challenges with the Ultrasonic Cable Welder. Improper setup can lead to weak welds and high rejection rates. It is crucial to understand the machine settings, materials, and techniques. Reports indicate that up to 30% of projects fail due to inadequate training. Training and hands-on experience should not be overlooked.

Moreover, calibration and maintenance of the Ultrasonic Cable Welder are vital to ensure optimal performance. Regular checks can prevent errors that might lead to wasted materials and time. A commitment to continuous improvement is necessary for success. Addressing these aspects can significantly enhance productivity and weld quality. Industry standards need to be met; otherwise, the outcome may fall short of expectations.

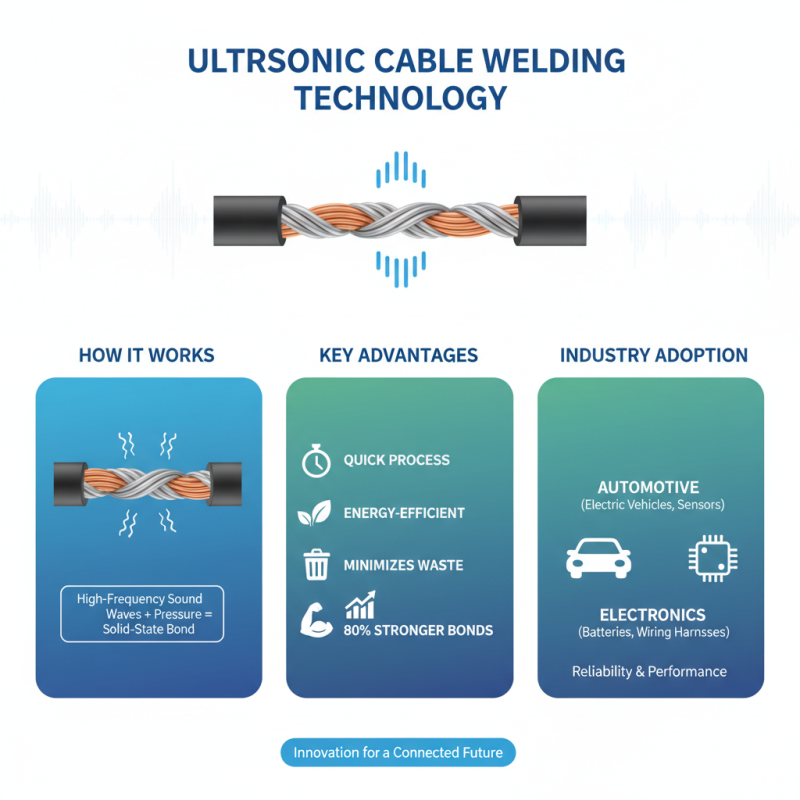

Ultrasonic cable welding technology has gained traction in various industries. This approach uses high-frequency sound waves to create a solid bond between materials. The process is quick and energy-efficient, minimizing waste. Recent industry reports indicate that ultrasonic welding can achieve bond strengths up to 80% higher than traditional methods. It is gaining popularity in the automotive and electronics sectors, where reliability is paramount.

One key to effective use of ultrasonic welding is understanding the parameters involved. Different materials require specific settings for optimum results. Factors such as frequency and pressure play significant roles in the welding process. Adjusting these parameters can lead to variable outcomes, making it essential to conduct initial tests before full-scale production.

Tips: Regularly monitor and calibrate your equipment. A well-maintained welder ensures consistent performance. Don't be afraid to experiment with settings. Sometimes, unexpected configurations yield excellent results, while over-familiarity could lead to stagnation. Always document changes. This practice will help refine processes over time, improving efficiency and output quality.

Ultrasonic cable welders are fascinating machines. They work using high-frequency sound waves to join materials. Understanding the key components is essential for effective use. Let's explore these parts in detail.

One vital component is the ultrasonic transducer. It converts electrical energy into mechanical energy. This transducer vibrates at a high frequency, creating intense pressure. It is usually paired with a booster. The booster amplifies the ultrasonic energy. The combination ensures a strong weld.

Another important part is the sonotrode or ultrasonic tip. This is the component that directly contacts the materials. It focuses the vibrational energy on the weld area. Proper selection of the sonotrode is critical. The size and shape affect the weld quality. Additionally, the fixture holds the cables firmly in place. Issues can occur if the cables shift during the process. Careful setup is essential to avoid mistakes. Attention to these components can lead to better results.

This bar chart displays the various efficiency metrics associated with an ultrasonic cable welder, including Weld Time, Power Consumption, and Material Thickness. These metrics are essential for assessing operational performance.

Setting up an ultrasonic cable welder can seem daunting. However, a straightforward process can ensure effective results. Begin by ensuring that all components are clean and in good condition. Dirt or defects can affect performance. According to recent industry reports, improper setup is a leading cause of operational failures, impacting up to 30% of production lines.

Next, configure the parameters based on your materials. Different materials require specific settings. Analyze previous results and adjust as necessary. Many operators overlook this, resulting in inconsistent welds. A study showed that 45% of issues stemmed from incorrect parameter adjustments. It's crucial to test small batches first.

After initial adjustments, monitor the welding process closely. Look out for inconsistencies in sound quality or weld strength. If any problems occur, revisit your settings. It's easy to miss details during busy production periods. Adapting quickly is key. Your goal is to achieve strong, uniform welds consistently. Remember, effective use of ultrasonic welders comes with practice and attention to detail.

| Step | Description | Time Required | Tools Needed |

|---|---|---|---|

| 1 | Prepare the materials | 15 minutes | Cable, ultrasonic welder |

| 2 | Set up the welder | 30 minutes | Screwdriver, manual |

| 3 | Test the equipment | 10 minutes | Multimeter |

| 4 | Perform welding | Varies | Protective gear |

| 5 | Inspect the weld | 5 minutes | Visual inspection tools |

Operating an ultrasonic cable welder requires precision and attention to detail. Best practices ensure effective and efficient welding. According to industry reports, improper adjustments can lead to weak welds or scrap materials. It is crucial to regularly calibrate the machine to maintain optimal performance.

Tips: Always check the amplitude settings before starting. Low amplitude may result in inadequate fusion. Periodically inspect the ultrasonic stack for wear. Worn components often lead to inconsistencies in weld quality.

Ultrasonic welding can be tricky. Many users face common challenges when working with this technology. Understanding these issues can make all the difference.

One frequent problem is poor weld strength. This can happen if the materials are not aligned correctly. Sometimes, the settings are simply off. Adjusting the amplitude or time can help. A machine running too fast may not fuse materials effectively. It’s vital to monitor these parameters closely.

Another issue arises from inconsistent heat distribution. This could lead to weak spots in the weld. Operators need to ensure that the parts are clean and dry. Contaminants can disrupt the welding process. Regular maintenance of the equipment is also crucial. Neglecting small details can lead to significant production issues.

Reflection on these aspects helps improve outcomes.