01

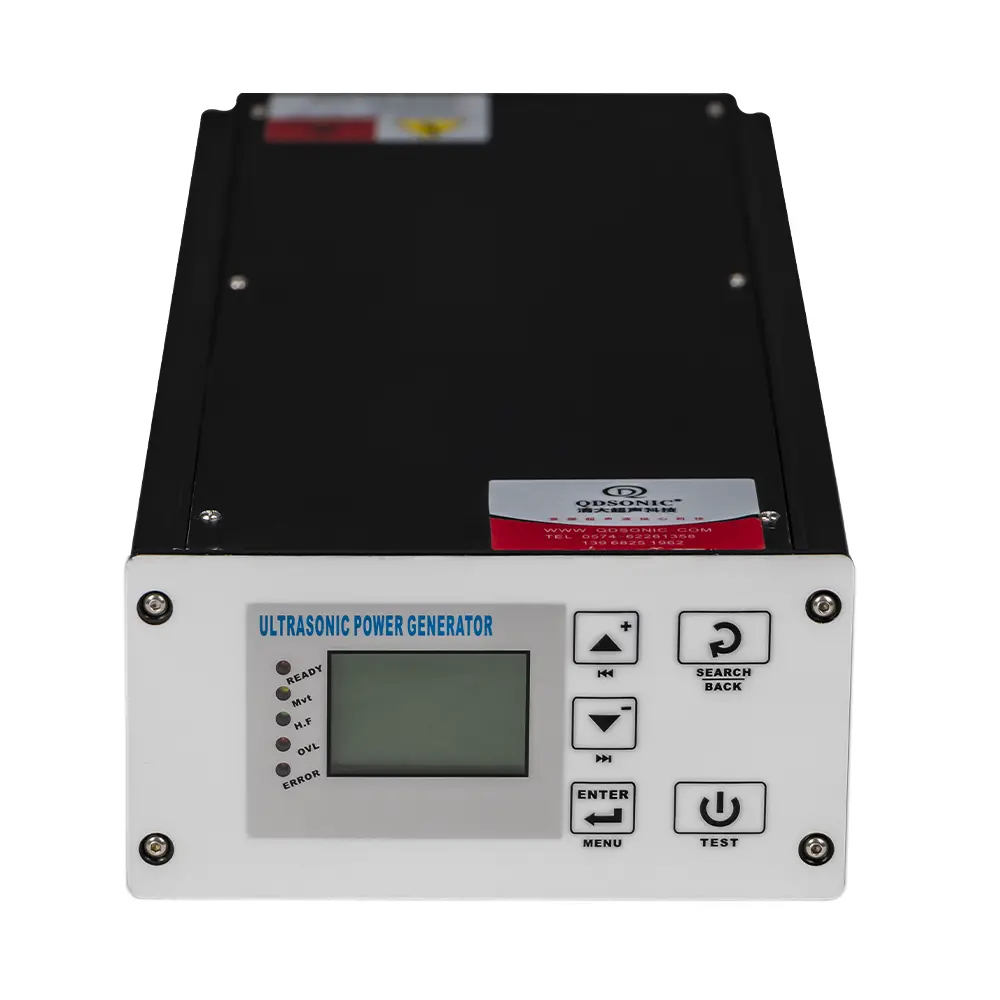

Industrial Ultrasonic Cleaning Machine Generato

Product Description

This generator offers the best adaptability for every application thanks to its intuitive interface, which lets you change the amplitude from 0 to 100. You can obtain excellent welds that are customized to meet your unique requirements, regardless of whether you're working with delicate materials or robust components. In addition to improving usability, the digital control circuit ensures system dependability, which lowers downtime and boosts overall production in a variety of industries.

This cutting-edge generator, which is built with accuracy and efficiency in mind, delivers remarkable output power that boosts your production capacities by automatically tracking and locking the frequency in real-time. It is therefore a vital tool for manufacturers seeking to improve their operations since it guarantees quicker cycle times and reliable results each and every time.

Selecting our Ultrasonic Digital Generator means making an investment in technology that puts performance first without sacrificing quality. Bid farewell to trial-and-error techniques; you'll experience smooth operation and reduced material waste with real-time frequency adjustment and strong design characteristics. Use the cutting-edge solution from Ningbo Qingda to improve your production process right now!

Selecting our Ultrasonic Digital Generator means making an investment in technology that puts performance first without sacrificing quality. Bid farewell to trial-and-error techniques; you'll experience smooth operation and reduced material waste with real-time frequency adjustment and strong design characteristics. Use the cutting-edge solution from Ningbo Qingda to improve your production process right now!

Product Advantages

● The entire ultrasonic industry chain is conducted independently, including research and development, production, and manufacture.

● Three welding modes: time mode, energy mode, and grounding mode.

● Protection against overload, amplitude correction, and mold impedance analysis and protection.

● Product power ranges from 800W to 4200W, and frequency ranges from 15K to 40K.

● Digital circuit system with real-time automatic frequency tracking and locking.

● Amplitude can be adjusted in steps of 10%-100%.

● voltage protection for the transducer and input.

● Aviation plug-in interface and PLC interface are options.

Product Precautions of use

1. Installation of the equipment:

Ensure that the equipment is installed in a smooth, dry environment to avoid the effects of humidity and high temperature environments on the equipment.

Follow the instructions provided by the manufacturer when installing the unit and ensure that all connections are firm and reliable.

2. Power Requirements:

Ensure that you use a power supply that meets the specifications of the equipment to avoid damage to the equipment caused by unstable voltage or overloading.

Periodically check the power cord and plug to ensure there is no wear or damage.

3. Frequency setting:

Before use, make sure the frequency setting of the equipment is correct and adjusted according to the characteristics of the material.

Avoid operating at an unsuitable frequency, which may affect welding quality or damage the equipment.

4. amplitude adjustment:

Before starting operation, adjust the amplitude to the proper level to avoid excessive amplitude that may cause material damage or poor welding.

During operation, adjust the amplitude gradually as needed to ensure welding quality.

5. SAFETY PROTECTION:

Wear appropriate personal protective equipment (e.g., gloves, goggles, etc.) during operation to prevent accidental injury.

Avoid placing hands or other body parts near the working area of the ultrasonic generator.

6. Regular Maintenance:

Clean and maintain the equipment on a regular basis to ensure its proper operation.

Check the condition of the ultrasonic transducer and other critical components and replace worn or damaged parts in a timely manner.

7. Operation Training:

Ensure that operators are properly trained on the operating procedures and safety precautions of the equipment.

It is not recommended that untrained personnel operate the equipment to avoid accidents caused by misuse.

8. Monitor the operating status:

During the operation of the equipment, regularly monitor its working status, note any abnormal sound or vibration, and stop the machine for inspection in time.

If equipment malfunction or abnormality is detected, stop using it immediately and contact a professional for overhaul.

By following these precautions for use, you can effectively improve the safety and efficiency of the digital ultrasonic power generator.